cnc machines use linear and circular __ for cutting moves G02 and G03 can be written in two versions Version 1 – “R” Syntax: 1. X, Y – The target coordinates at the end of the movement. 2. R – The arc’s radius. 3. F – The feedrate(Speed) at which the machine will move from the current position to the target position. . See more Junction box for waterproof underground connections • Cable box AK1-IP65 M20/M25 as complete cast resin joint package for water-tight underground connections. • Including 2-component PUR cast resin in transparant mixing bag.

0 · linear interpolation on cnc

1 · cnc linear and circular interpolation

2 · circular interpolation cnc machine

Outdoor Extension Cord Box, Large Waterproof Electrical Cord Box Plug Protector Cable Connection Safety Cover IP54 Water-Resistant for Power Strip, Holiday Light and Decorations, Black

linear interpolation on cnc

emt electrical boxes

G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the effective mode (G90 or G91). This type of movement is called Circular interpolation. See moreWith both commands, the machine will move from its current position to the same target coordinate. In G02, the movement will be clockwise (CW), and in G03, counter-clockwise (CCW). See moreG02 and G03 can be written in two versions Version 1 – “R” Syntax: 1. X, Y – The target coordinates at the end of the movement. 2. R – The arc’s radius. 3. F – The feedrate(Speed) at which the machine will move from the current position to the target position. . See moreOur recommendation is that the IJK format should always be used as it is fully defined, eliminating any confusion or errors! See more

Example #1 – CW movement along the Blue Arc in AbsoluteMode – “R” Syntax. Example #2 – CCW movement along the Orange Arc in AbsoluteMode – “IJK” Syntax. Example #3 . See more

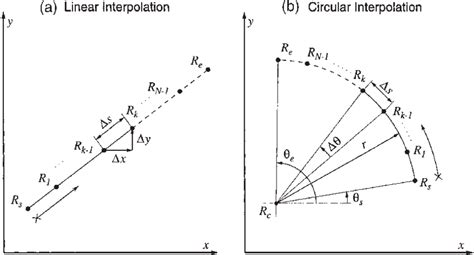

CNC machines therefore require linear and circular interpolation. In this context, linear cutting movement is one of the most common movements in part processing. The C and R parameters, which are used with the G01 code, . G-codes focus on controlling the geometry and movement of the CNC machine, dictating how the tool should move along different axes and the paths it should follow to create . Linear interpolation involves the cutting tool moving in a straight line between two points, while circular interpolation follows a circular path. Interpolation in CNC machines is crucial for achieving high-quality machining .CNC programming involves writing instructions that dictate how a CNC machine operates, including movements, speeds, and tool changes. These instructions are typically written in a .

G01 – Linear interpolation (Cutting in a straight line): Moves the tool in a straight line at a specified feed rate. G02 – Circular interpolation (Clockwise arc): Moves the tool in a .

Common G-code commands include G00 for rapid positioning, G01 for linear interpolation (cutting in a straight line), G02 and G03 for circular interpolation (clockwise and counterclockwise arcs), and G17/G18/G19 for .Milling machines use G and M codes to control the movement of the cutting tool in three linear axes (X, Y, and Z). They're used for creating flat or contoured surfaces, slots, pockets, and . During thread milling, the machine must move in a circular manner along two axes (usually X and Y) at the same time a third axis (usually Z) moves in a linear manner. This .

cnc linear and circular interpolation

G00 – Rapid Travel. Often referred to as rapid traverse, G00 moves the CNC at the highest speed possible from its current position to its next one. Rapid moves can be placed anywhere in the program, especially at its . Using a constant feed rate for linear and circular milling leads to chatter — most times, increase feed rate on external arcs and decrease it for internal. . a CNC machine where to position the cutting tool during the .7.How does a cutting tool move during a G86 rough-boring cycle after it feeds into the hole? Once the tool reaches the hole's Z depth, the: . 11.Which two types of canned cycles are specialized for CNC machines designed for conversational programming? . One of the internal circular milling cycles initiates circular pocket milling: In a .Linear interpolation moves the cutting tool in a(n) _____ line path between two points. straight. Most modern CNC machines employ a high-tech modernized version of ways called _____. linear guides. Programming code that the CNC machine can understand is called _____ address.

I found out that my Y axis linear bearings were way too tight. Once I disconnected the Y motor, I could barely move it along the rails. The linear bearings have small set screws that will tighten the bearing around the rail - so I loosened them up so I had free movement along Y and did another circular pocket test and now all is well.

It looks like there's more and more high end cnc machines with linear motors instead of servo's and ballscrews. . It was the only time I witnessed a cut on such a machine. John . B. BobWelland Stainless. Joined Sep 30, 2002 Location . Again, they are linear as opposed to circular but the concept is identical. Sometimes, the coils avoid the . But if you're painting, or arc welding, or laser-cutting, or laying a glue pattern, Linear is really the only way to go. Circular moves are the same as Linear moves, it's just that the tool follows a defined curve instead of a straight line. For short distances, the difference between a Joint and Linear move can become almost inconsequential .

For example, CNC machines and 3D printers use G-code to make parts. Programming arcs and linear movement in G-code can be a little tricky. I've noticed that there aren't many sources on the internet that address this topic. So, I decided to make my own guide. I will be presenting basics steps and tips in programming arcs and linear movement in . If we want the CNC machine to cut a circle pocket in a rightward trajectory, we use G12 for clockwise movements; otherwise, we should use this command but in a counterclockwise direction — g13. Despite having like parameters (center point of the pocket and depth), these commands fundamentally alter tool path and cutting dynamics. Most CNC machines use the G-code standard. Some machines have sophisticated features or numerous axes that are not controlled by regular G-code commands. . Shows a linear interpolated motion command. X10, Y5: Defines the end point of . Function: Without cutting, it quickly moves the tool to a designated position. Example: G00 X10 Y5. G01 . G-Codes control movements, ranging from simple linear motions to complicated circular interpolations. They include commands such as spindle speed, tool length compensation, cutter compensation, and work offsets. . enabling the CNC machine to move the cutting tool in a predetermined way. G Code Example for CNC Milling and Turning Processes. A .

Recognize the Original Position: Identify the arc’s starting point (X, Y). Set these points into motion through an initial move command as part of your CNC program. State G02 Order: Use a clockwise rotation to determine travel around an arc by putting G02 in a CNC program. This tells the machine that it will be doing circular interpolation. G00 is a G-code command that instructs the CNC machine to move the tool or the workpiece to a specified position at the maximum possible speed. . start spindle and set speed) G00 X10 Y10 (Rapid move to starting point of cutting) G01 Z-5 F100 (Linear move to cutting depth with feed rate) G01 X90 Y10 F200 (Linear move along X-axis with feed .

Generated g – code represents a set of instructions which tells CNC machine how to move cutting tools, spin spindle and apply coolant if needed. Different settings can be adjusted by users such as cutting speed and depth of cut to maximize production efficiency while ensuring quality finish for the part produced. Moves the machine at its maximum travel speed. G1: Linear interpolation command. Moves the machine in a straight line at a specified feed rate. G2 and G3: Circular interpolation commands. Moves the machine in a circular pattern. G20 and G21: Units selection commands. Set the units to inches or millimeters. G28: Return home command. Moves the . In order to show the effect of the proposed algorithm, two different tool paths consisting of three linear segments are given in which J max = 1000 mm / s 3, A max = 100 mm / s 2, V max = 50 mm / s and T s = 1 ms.Also, it is assumed that the machine is usual 3-axis CNC-Milling, the maximum angular acceleration value of the axis motors is 200,000 deg/ s 2 (3490 . 3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is .

CNC (Computer Numerical Control) part programming is the process of creating a set of instructions for CNC machines to manufacture parts. These instructions, or programs, are written using G-code (Geometric code), a programming language that CNC machines understand.A machine tool that uses computer numerical data to control cutting operations on flat, square, or rectangular workpieces. On a CNC mill, the cutting tool rotates against a workpiece that is fixed to a worktable. The G07 command is often used by CNC programmers in conjunction with G01 (linear interpolation) or G02/G03 (circular interpolation) commands to maneuver through intricate shapes. By allowing continual engagement between the cutting edge and workpiece, cylindrical interpolation can greatly reduce cutting time while improving finish quality.G02 and G03 are used for defining circular and helical motions. G02 stands for CW (Clockwise) circular interpolation,indicating a circular path that moves in the same direction as a clock. On the other hand,G03 represents CCW (Counter Clockwise) circular interpolation,marking a circular path that moves against the clock's direction. G04 - Dwell

The most recognizable coordinates can be found on the vertical CNC mill.When facing the machine, its coordinates follow the right-hand rule. The X axis describes left and right motion of the cutting tool, the Y axis describes motion of the tool in and out, or towards and away from the operator, and the Z axis describes up and down motion. Depending on the machine, .Study with Quizlet and memorize flashcards containing terms like G-code, Absolute Positioning, Linear Guides and more.

A method for programming circular tool movements that requires an I code and a J code to indicate the locations of the arc's center along with the X and Y codes that note a point along the arc's periphery . On a CNC lathe, the cutting tool moves against the rotating workpiece. . lubricate, and clear chips during metal cutting. Coolant use . IntroductIon Computer Numerical Control (CNC) systems are the "back-bones" of modern manufacturing industry for over the last 50 years and the machine tools have evolved from simple machines with .Circular interpolation. Commanded by the G-codes G2 or G3, a type of motion that causes the cutter's path to travel in an arc so that CNC machines can cut full or partial circles. . CNC motion used to move the tool in a straight line along one or more machine axis. Machining center. 1. Analysis of the Relationship Between Machine Tool and Workpiece Coordinate Systems. The machine tool coordinate system, also known as the mechanical coordinate system, is established by the machine tool manufacturers to determine the positions of the workpiece, cutting tool, and others within the machine.. Upon startup, the machine typically locates the .

Canned Cycles for the Mill provides an overview of the standard canned cycles used on CNC mills. A canned cycle is a repeatable block in a part program that acts as a programming shortcut for common cutting operations. CNC controls typically offer standard canned cycles, manufacturer cycles, and customized cycles. Most CNC mills offer holemaking canned cycles and some .

With a rating of IP66, Masterseal Plus™ offers total protection against dust, and is protected against high pressure jets of water from any direction. Masterseal Plus™ sockets can seal around virtually any standard 13A plug – including moulded plugs – .

cnc machines use linear and circular __ for cutting moves|cnc linear and circular interpolation