carbon fiber parts cnc machining Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very competitive prices. Contact us now! Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time. CANTEX LEZ55QNB EZ BOX is a 55 cu. in. 4-gang nail-on electrical switch and outlet box for residential or light commercial new construction (new work) electrical installations. It features an adjustable metal bracket for quick mounting between studs as well as 12 wire clamps and enhanced angled nails for EZ installation.

0 · water jet cutting carbon fiber

1 · how to cut carbon fibre

2 · end mill for carbon fiber

3 · desktop cnc for carbon fiber

4 · cnc carbon fiber sheets

5 · cnc carbon fiber cutting service

6 · carbon fiber machining near me

7 · carbon fiber cnc cutting

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), .

Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very . Carbon fiber surpasses conventional CNC machining materials such as .

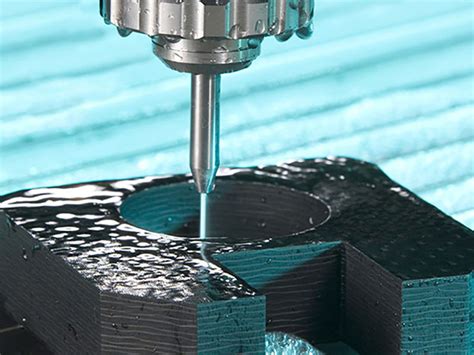

Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very competitive prices. Contact us now! Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router. However, other standard machining methods are also effective. Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in .

What is Carbon Fiber Machining? Carbon fiber machining involves a series of cutting and fashioning composites of carbon fiber to give you functional carbon fiber components like heat shields and golf clubs. The unique nature of carbon fiber presents a number of machining challenges meaning you have to adopt specialized machining techniques.

Whether you need one part or 1,000, we have the tools and equipment to make precise cuts to the most stringent requirements. With three CNC machines available to accommodate varying needs, our in-house machining team can cut your carbon fiber parts to a tolerance of 0.005” to ensure a perfect fit every time.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

As an ISO 9001:2015, AS9100 Rev D, and ITAR certified company, our CNC carbon fiber parts are manufactured and designed with the quality and reliability you can depend on for high-performance carbon fiber composite parts.

Tech Part d.o.o. specialises in delivering high-quality Carbon Fibre Reinforced Polymer (CFRP) products through state-of-the-art CNC machining and moulding techniques. Our expert team and cutting-edge technology ensure precision, reliability, and excellence in every project.

RapidDone utilizes typical CNC turn machines to create round-shaped carbon fiber parts with diameters up to 300mm. Our in-house turn mill machines enable the production of complex turned parts with milling features.Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very competitive prices. Contact us now! Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time.

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router. However, other standard machining methods are also effective.

Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in . What is Carbon Fiber Machining? Carbon fiber machining involves a series of cutting and fashioning composites of carbon fiber to give you functional carbon fiber components like heat shields and golf clubs. The unique nature of carbon fiber presents a number of machining challenges meaning you have to adopt specialized machining techniques.

Whether you need one part or 1,000, we have the tools and equipment to make precise cuts to the most stringent requirements. With three CNC machines available to accommodate varying needs, our in-house machining team can cut your carbon fiber parts to a tolerance of 0.005” to ensure a perfect fit every time.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.As an ISO 9001:2015, AS9100 Rev D, and ITAR certified company, our CNC carbon fiber parts are manufactured and designed with the quality and reliability you can depend on for high-performance carbon fiber composite parts.

Tech Part d.o.o. specialises in delivering high-quality Carbon Fibre Reinforced Polymer (CFRP) products through state-of-the-art CNC machining and moulding techniques. Our expert team and cutting-edge technology ensure precision, reliability, and excellence in every project.

water jet cutting carbon fiber

how to cut carbon fibre

The Mainstays Under Cabinet Baskets have helped me organize my pantry. Both baskets are the color white and are built out of metal. The baskets are easy to hang and slide onto any shelf size.

carbon fiber parts cnc machining|water jet cutting carbon fiber