2 types of sheet metal screws What Are The Two 2 Types Of Sheet Metal Screws? Sheet metal screws are primarily used for connecting metal sheets, allowing them to be fastened not only to other metal objects but also to surfaces made of various . Mix and match the 222 and 773 series connectors to suit the job with up to 24 individual terminations; Dimensions: 108 x 44 x 39mm; Complies with BS EN 60670-22; Configurable to BS 5733-MF; Meets all the requirements of the 17th Edition of BS 7671The 222 Series Lever-Nuts® is the original lever-operated connector for standard or solid wires. It supports various wire sizes, combines different types, and ensures low cost, safety, .

0 · strongest screws for metal

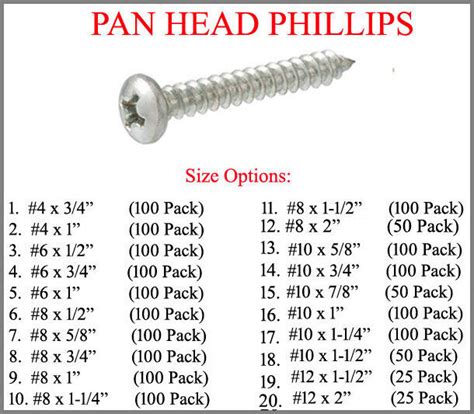

1 · standard sheet metal screw sizes

2 · size 16 sheet metal screws

3 · sheet metal screws for shelving

4 · sheet metal screw sizes explained

5 · self tapping screws for metal

6 · metal screw 1 2 inch

7 · 5 inch sheet metal screws

headlight bucket support panel; front floor/ floor sections; front wheel wells/repair sections; fatlip 2 piece doglegs 56/62; thinlip 2 piece doglegs 62/67; front doors; b pillar driver's side lhd bus and d/c (left side), from 59/67; bus/double cab cabin separation panel; rear. rear bumpers; rear engine area sheet metal; rear corners; battery .

strongest screws for metal

What Are The Two 2 Types Of Sheet Metal Screws? Sheet metal screws are primarily used for connecting metal sheets, allowing them to be fastened not only to other metal objects but also to surfaces made of various . Commonly there are two types of metal sheet screws available in the market. While standard units feature a pointed tip, which is ideal for cutting into the metal surface, the thread-cutting or self tapping screws feature a notched .

Choose the right type of screw with the necessary coating: zinc plating screws for minimal basics protection, screws with a hot-dip galvanising for the outside purposes steel ЛС118, or grades .

holzinger sheet metal

For some projects, screws are placed 24 inches apart in sheet metal. What are the two types of sheet metal screws? Self-tapping and self-drilling screws are the most common screws used with sheet metal. Both . Sheet metal screws are versatile fasteners that can be used with various materials, including metal, plastics, rubber, and plywood. When working with sheet metal . Sheet metal screws are used for a variety of applications, including metal, wood, fibreglass, and plastic. They are fully threaded for a strong, secure hold and are reusable and . The real difference between these two types of sheet metal screws is in the threaded portion of the fastener. Type A sheet metal screws feature a coarse thread, while Type AB sheet metal screws feature a fine thread. .

There are two main types of sheet metal screws: self-tapping and self-drilling. Self-tapping screws have a gimlet point and require pre-drilling, while self-drilling screws have a . There are two basic types of sheet metal screws, self-tapping screws and self-drilling screws. Self-tapping screws have a sharp tip that is designed to cut through metal, but the metal must be pre-drilled before these .

Sheet Metal Screw Types. Like any hardware, fasteners are available in different materials, lengths and gauges. They also have different point, head and slot variations. The two main types of sheet metal screws are self-tapping and self-drilling, each having many features to choose from. Self-Tapping Sheet Metal Screws What Are The Two 2 Types Of Sheet Metal Screws? Sheet metal screws are primarily used for connecting metal sheets, allowing them to be fastened not only to other metal objects but also to surfaces made of various materials such as plastic, aluminum, plywood, hard rubber, or wood.

Commonly there are two types of metal sheet screws available in the market. While standard units feature a pointed tip, which is ideal for cutting into the metal surface, the thread-cutting or self tapping screws feature a notched tip, which can easily cut into the metallic surface without pre-drilling.Choose the right type of screw with the necessary coating: zinc plating screws for minimal basics protection, screws with a hot-dip galvanising for the outside purposes steel ЛС118, or grades 304/ 316 stainless steel screws for the very tough conditions. For some projects, screws are placed 24 inches apart in sheet metal. What are the two types of sheet metal screws? Self-tapping and self-drilling screws are the most common screws used with sheet metal. Both types of screws are available at hardware stores. Sheet metal screws are versatile fasteners that can be used with various materials, including metal, plastics, rubber, and plywood. When working with sheet metal screws, it is crucial to select the appropriate size and type for your specific project.

Sheet metal screws are used for a variety of applications, including metal, wood, fibreglass, and plastic. They are fully threaded for a strong, secure hold and are reusable and removable, making maintenance and repair easy. The real difference between these two types of sheet metal screws is in the threaded portion of the fastener. Type A sheet metal screws feature a coarse thread, while Type AB sheet metal screws feature a fine thread. Because they feature a higher number of threads per inch, Type AB sheet metal screws offer broader functional capabilities than .

There are two main types of sheet metal screws: self-tapping and self-drilling. Self-tapping screws have a gimlet point and require pre-drilling, while self-drilling screws have a drill point and do not require pre-drilling.

There are two basic types of sheet metal screws, self-tapping screws and self-drilling screws. Self-tapping screws have a sharp tip that is designed to cut through metal, but the metal must be pre-drilled before these screws can be used. Self-drilling screws have a drill point tip that can easily cut through metal without a pre-drilled hole.

Sheet Metal Screw Types. Like any hardware, fasteners are available in different materials, lengths and gauges. They also have different point, head and slot variations. The two main types of sheet metal screws are self-tapping and self-drilling, each having many features to choose from. Self-Tapping Sheet Metal Screws What Are The Two 2 Types Of Sheet Metal Screws? Sheet metal screws are primarily used for connecting metal sheets, allowing them to be fastened not only to other metal objects but also to surfaces made of various materials such as plastic, aluminum, plywood, hard rubber, or wood. Commonly there are two types of metal sheet screws available in the market. While standard units feature a pointed tip, which is ideal for cutting into the metal surface, the thread-cutting or self tapping screws feature a notched tip, which can easily cut into the metallic surface without pre-drilling.Choose the right type of screw with the necessary coating: zinc plating screws for minimal basics protection, screws with a hot-dip galvanising for the outside purposes steel ЛС118, or grades 304/ 316 stainless steel screws for the very tough conditions.

For some projects, screws are placed 24 inches apart in sheet metal. What are the two types of sheet metal screws? Self-tapping and self-drilling screws are the most common screws used with sheet metal. Both types of screws are available at hardware stores. Sheet metal screws are versatile fasteners that can be used with various materials, including metal, plastics, rubber, and plywood. When working with sheet metal screws, it is crucial to select the appropriate size and type for your specific project. Sheet metal screws are used for a variety of applications, including metal, wood, fibreglass, and plastic. They are fully threaded for a strong, secure hold and are reusable and removable, making maintenance and repair easy.

The real difference between these two types of sheet metal screws is in the threaded portion of the fastener. Type A sheet metal screws feature a coarse thread, while Type AB sheet metal screws feature a fine thread. Because they feature a higher number of threads per inch, Type AB sheet metal screws offer broader functional capabilities than . There are two main types of sheet metal screws: self-tapping and self-drilling. Self-tapping screws have a gimlet point and require pre-drilling, while self-drilling screws have a drill point and do not require pre-drilling.

hogan box electrical

WABECO CC-D6000. CNC lathes with prismatic cast bed and NCCAD BASIC or PROFI control and turning software

2 types of sheet metal screws|sheet metal screw sizes explained