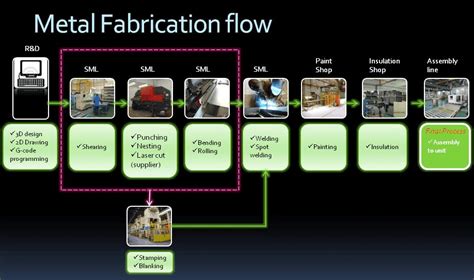

sheet metal fabrication process flow chart Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

Find Exterior electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

0 · sheet metal rib design guidelines

1 · sheet metal manufacturing process types

2 · sheet metal layout techniques

3 · sheet metal fabrication layout tools

4 · sheet metal fabrication handbook pdf

5 · sheet metal design guide pdf

6 · sheet metal basic design guidelines

7 · basic sheet metal fabrication techniques

Metal brackets come in various sizes, shapes, angles, and complexities to meet the demands of countless applications. Valued for their dependability, durability, strength, and versatility, they play a crucial role in structural designs.

sheet metal rib design guidelines

Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Sheet Metal Fabrication is the process of forming metal sheets into structures or parts using various techniques such as cutting, bending, and welding. This process commonly use for . An Overview of Sheet Metal Design Process flow. The comprehensive process flow for sheet metal design involves the following phases: Ideation. The first step in designing with sheet metal is establishing your .

fire code baltimore county electrical box access

sheet metal manufacturing process types

A complete guide on processes, applications, pros, and cons. Discover essential tips and techniques in our comprehensive guide to sheet metal fabrication for both beginners and professionals.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. In this blog, we explore the process of sheet metal fabrication and the various techniques involved. This includes heating, bending, notching, shrinking, and beading. We’ll delve into each step to give you a . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other . Sheet metal fabrication is a versatile manufacturing process with an extensive list of techniques and usable metals. Getting familiar with the technology, how it works, and its applications will help you decide if it is the .

\n\nTO-Steel Fabrication provides businesses with custom solutions to their steel fabrication needs. Our team can accurately assess, design and manufacture any steel structures with the highest quality standards. Our precision and attention to detail in fabrication allows us to ensure the safety and integrity of any structure during installation and beyond.

Basic-Fabrication-Process-Flowchart - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document outlines the fabrication process flowchart for welding steel components. It includes steps for material . Tim Heston, The Fabricator's senior editor, has covered the metal fabrication industry since 1998, starting his career at the American Welding Society's Welding Journal. Since then he has covered the full range of metal . What Are the Basic Steps of Metal Fabrication? Because the metal fabrication business has applications in nearly every industry, there are many different processes and techniques that are used to create an endless variety of products. The floor of a metal fabrication shop is a diverse place full of tools for cutting, stamping, bending, hole .

Review and understand the project specifications Take the time to thoroughly review and understand the project specifications. This task is crucial for ensuring that the fabrication process meets the required standards and the final product meets the client's expectations. Consider the materials, dimensions, design requirements, and any specific quality control measures . Sheet metal products processing flow chart by Suzhou Houdry. . Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. . in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the. China Internation . Rolled metal sheets are used for sheet fabrication. These sheets are rectangular and flat. Therefore, the first step of any sheet fabrication is cutting. In this process, a metal sheet is cut or removed by applying a strong force. Also, the sheet metal cutting process is performed using a variety of basic to advanced cutting tools. For instance .

fire proof electrical boxes

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms. . Here the metal flow is uniform along the bend axis with the inner .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight

The sheet metal fabrication process involves several fabrication techniques that cut, form, or join metal into custom parts and components that are further utilized in a wide range of applications. Whether building complex structures and advanced machinery or standard tools and devices, the process selectively removes, reforms, or combines material to create the .

Download scientific diagram | Flow chart of the fabrication process. from publication: Fabrication of Porous SiC Ceramics with Special Morphologies by Sacrificing Template Method | Sacrificial .The cutting sheet also serves to control the flow of material in the early stages of fabrication, traveling with a group of beams through each stage in the plant, allowing employees to know where a beam is at all times and which processes have already been performed on it. big Tools After the material handler locates our Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing. In this article, we cover the basics of sheet metal fabrication, from material selection to key .Sheet metal fabrication is the process of forming a metal sheet into a desired shape. This is a popular manufacturing process that uses metal sheets for creation of a product. The process is widely used in the metal manufacturing industry. There are a few steps involved in converting a metal sheet into the product. These

In this guide, you’ll learn the seven crucial steps in the sheet metal fabrication process, helping you understand how to achieve top-notch results for your business. So let’s get started! Step#1 Design and Development. The initial .This paper illustrates process flow chart and factors affecting the production of a jute mills in Bangladesh. Akij jute mills is a 100% export oriented Jute yarn Industry catering to the need to carpet manufacturers and other end users of .

Fasteners are riveted to sheet metal parts. Pressure riveting is commonly used in pressure riveting bolts, compression riveting nuts, pressure riveting screws, etc. . The above is the flow of metal stamping process and a .Sheet metal fabrication process flow chart Transport procedure for storage of inbound goods Operation / Function of organization of inspection edition 2-part function Decision 1 (TQM) Decision 2 (TQM) Multi in/out Decision (multiple inputs on the right) Multi in/out Decision (Multi-In input on the left) External organization External inspection . It is necessary to create a path for electricity to pass through according to the circuit pattern. This process is called the metal wiring process. It is a process that allows electricity to flow by depositing a thin metal film using materials such as aluminum, titanium or tungsten so that electricity can pass through the semiconductor wells. PS:

Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc.Download scientific diagram | Fabrication process flow chart. from publication: Evaluation of Mechanical Behavior of Jute Fibre-Aluminum Powder Reinforced Hybrid Polymer Composites | Abstract: The . The sheet metal fabrication process consists of two main processes; forming and cutting. . based on the direction of airflow and the location of any potential obstructions or obstacles that could affect the flow of air. . Here is a chart showing the recommended material thickness for some common metals used in sheet metal fabrication. Metal .ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents. It is includes rich examples, templates, process flowchart symbols. ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart .

The Language of Composition: Reading, Writing, Rhetoric 2nd Edition • ISBN: 9780312676506 Lawrence Scanlon, Renee H. Shea, Robin Dissin AufsesProcess Flow Chart: K.K. Metals manufacture the best quality hot closed die forgings. Good quality forgings are always a result of two things. Good intentions, values, and management commitment. Good Manufacturing process.

This document provides fabrication procedures for structural steel work. It outlines requirements for materials, shop drawings, fabrication, safety, inspection, and painting. The fabrication process includes cutting, drilling, assembling, welding, repair, and quality control checks. Tolerances for welding and fabrication are specified in appendices. The goal is to fabricate structural steel .

The term “sheet metal fabrication” describes the process of transforming flat metal sheets into metal products and structural designs. Most sheet metal processing techniques include converting various sheet metal types into components and parts by employing precision equipment like a CNC machine and several forming methods.

sheet metal layout techniques

We’ve put together this simple guide so you can pick all locks without having to rack your brain on how to do it and decide what types of lock is best for your particular needs. By learning about each lock type, you can become a better picker no matter what situation you find yourself in.

sheet metal fabrication process flow chart|sheet metal manufacturing process types