how to draw sheet metal fittings How to Draw Duct and Fittings | UTM. Let us know what you like or dislike. or don't! See what other HVAC training videos we have. Link to Cut Sheets (teammechanical.com/daily-forms). There are some box/brackets that attach to steel studs without fasteners (for certain cases.) https://www.hubbell.com/raco/en/Products/Electrical-Electronic/Boxes/Nonmetallic-Boxes-Accessories/BOX-LOC-Metal-Stud-Clip/p/141362?queryID=62bcc279f65754c9b8357a90624134fb&indexName=Products

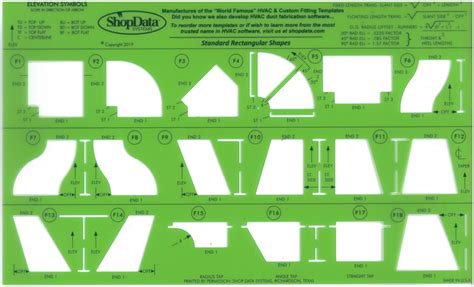

0 · sheet metal fitting template

1 · sheet metal duct work template

2 · sheet metal duct fitting template

3 · sheet metal die design pdf

4 · sheet metal design guidelines pdf

5 · sheet metal design calculations pdf

6 · free sheet metal layout software

7 · free sheet metal layout patterns

Round Boxes for Light Fixtures. Round electrical boxes are used for wall-mounted light fixtures, such as sconces. They are designed to support .

How to Draw Duct and Fittings | UTM. Let us know what you like or dislike. or don't! See what other HVAC training videos we have. Link to Cut Sheets (teammechanical.com/daily-forms). This is a simple video showing one functional way to begin drawing a sheet metal fitting or piece of duct isometrically in freehand and not to scale. Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creating rectangular duct, end caps, radius.

You would have your external sheet metal duct or fitting material (#1) with acoustical liner (#2) fasten with adhesive and sandwiched with the perforated metal (#3). This is done in all shapes of ductwork and fittings, .

From the shop drawings the detailer will either draw the required duct and fittings onto an order form or the CAD software will download the information to the shop fabrication equipment with or without the shop . Learn how to create sheet metal fabricated parts with our free online tutorials.

Twisted Fitting. Because the top and bottom are parallel, triangulation from plan view will be used. This is a much quicker way to develop the pattern, compared to using elevation view. Draw a plan view complete with element lines and .

Our Transitional elbow will be offset from one side only. Here you will layout a 90 Deg. elbow 8/12 to 8/10 keeping one side straight. Draw your flat side pattern and bisect the heel and throat curves, establishing points 3 & 6.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points . While we were building our new sealed room we needed a custom duct made to connect this our air filtration’s exhaust to the outside of the room. We go throug.

Draw a plan view complete with element lines and labeling. Label the top with 1-4 and A-D for the bottom. This is one of the only fittings I like to label a square or rectangle with numbers. Draw a true length diagram (TLD) with the vertical .Double wall, or dual wall, spiral duct fittings are another popular type of duct fitting. These dual-wall round ducts are often used when the duct will be exposed, such as in industrial settings. DC Duct and Sheet Metal LLC offers acoustical . Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control

7 Snap-Lock Technology Galvanized Pipe, Round and Oval 14" Pipe 16" Pipe 18" Pipe 20" Pipe 24" Pipe 12" Pipe 10" Pipe 9" Pipe Length Gauge Item# 2' 24 140209 Drawings will need to be converted to a flat pattern for fabrication, however, and 2D drawings are far more useable in sheet metal manufacturing. Where 3D drawings are used, they should be made with a sheet metal module, and good design practices should be followed so that the 3D dimensions match the 2D design.the video contains the illustrations and a steps by steps guidance to draw a given right cone.Msogiji Drawing academy is always there for you, ️😍for other .

i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a .JJ Electrofab is Specialist in sheet metal fabrication and manufacturing of Electrical Control Panels, Enclosure for automation, Cabinets, Acoustic Enclosures. . the best way to see the true lengths in a square to round fitting is to draw a top view of the fitting as we did above. You need to develop a true length bar. Using your dividers or .

1.5 Pressure Loss in Supply Fittings...1.17 1.5.1 Loss Coefficients . Sheet Metal and Air Conditioning Contractors National Association (SMACNA), 1990 Chantilly, VA...A. 95 . Duct System Design . Duct System Design .The fab was the easy part dawg. Puttin that 1 3/8" duct-mate frame on a 1" flange and still get that fuckin' rawend to hit that sweet gooey mastick inside lol.On this lazy Sunday, I show you step by step how to build sheet metal rectangular duct, and how to make a field Pittsburgh seam. HVAC has been very good to .A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create. This article will focus on how to prepare accurate and easy to interpret sheet metal drawings so .

Here we show you how to adjust a round sheet metal duct elbow for 90°, 45°, 35° or from 0° to 90° or anything in between. It may seem confusing adjusting a r. Sheet Metal Takeoff We will cover the steps needed in order to do an accurate and thorough takeoff of the sheet metal. Now that you have learned how to recognize round and rectangular ductwork, fittings and specialties, we . This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.

Sheet metal elbows can be fabricated from a variety of materials, including galvanized steel, stainless steel, aluminum, and copper. The choice of material will depend on factors such as the application, environmental conditions, and budget. The thickness of the sheet metal used in elbow fabrication is also an important consideration.Discover top-quality sheet metal fittings at HVAC Premium. We offer elbows, reducers, stick-on collars, end caps, 90-degree elbows, straight & angled register boots, straight stack boots, and much more. Free shipping, various sizes, and excellent customer service. Shop now for competitive prices and fast delivery!I bought a book for a sheet metal class I took at my local college. Practice drawing the examples in the book with graph paper. Be precise, use rulers and compass, etc. Do some of the same examples with different dimensions. When you get to bringing your drawing into reality make sure you use a sharpie to indicate what piece is which.

Use the last marks to draw a straight line across the width of the sheet metal. Cut the sheet metal along this line. Insert the end of the cut piece of metal marked at 1 inch into the lock-former machine. Turn the machine on. Open the clamp mechanism of your sheet-metal break and insert the end of the metal with the lock-form. More often, transitions are made in four pieces in order to save both time and sheet metal. . Draw a true length triangle (Figure 5A) to determine the true length of the centerline (KL) of Side 1 in Figure 4. . Excerpted and reprinted from Layout for Duct Fittings by Leo A. Meyer, one of the books in the Indoor Environment Technician's .

“Duct Guardian” is a sheet metal program that calculates flat (unfolded) sheet development of ducts, rectangle to round transitions, cylinders, cones, pipe intersections, connections, bifurcations, elbows, etc. . or mid cross sectional dimensions and / or height specifications; to draw or not the 3D surface, and the unfolded sheet as a . These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD software provides related tools and functions for sheet metal design. For example, Creo offers a variety of methods for . Michael Housh from Housh Home Energy Experts shares his expertise with HVAC School. In this video, he shows how to make a sheet metal duct transition in the .Not too long ago I, like many of you, sincerely thought that the way of making any kinds of sheet metal fittings is only possible by using sheet metal brake and metal forming machines! Not anymore: From late Fall and Winter of 2015 through May 2016 I made more than twenty most frequently-used sheet metal fittings without using any of these very .

Here is how spiral fittings can help prevent serious and potentially costly ductwork leakage: Low Weight — Spiral fitting ducts have the lowest weight availalbe with the same pressures, airflows, and friction loss.; Fewer Supports — Spiral fitting ducts require fewer supports per foot.; Affordable — Spiral fitting ducts are the least expensive to seal in order to reduce air leakage. Tips to calculate bend deduction in CAD software: Create sheet metal part: Start by creating or importing your 3D sheet metal model in SolidWorks. Define material and thickness: Ensure that you have defined the correct material and thickness for your sheet metal part. This information is crucial for calculating the bend deduction accurately.

sheet metal fitting template

sheet metal duct work template

sheet metal duct fitting template

Magnesium, an alternative to aluminum, is used as a primary alloy for an increasing number of laptop designs. It's lighter by volume than aluminum by approximately 30% (it's actually the lightest structurally-used metal in the world), while having a .

how to draw sheet metal fittings|sheet metal design guidelines pdf