sheet metal cone development formula We are providing this example solution Checking Method to you so that you can easily verify your calculated values with some standard . See more Here's an update on my $100 bargain purchase of an 8-year old Summit. Most of you know - but perhaps some do not - that the firebox on the Summit (including the current version) is NOT made of a single piece of cast aluminum.

0 · truncated cone template calculator

1 · printable cone template calculator

2 · frustum cone weight calculator

3 · cone weight calculator in mm

4 · cone template calculator

5 · cone sheet metal calculator

6 · cone layout calculator

7 · cone development calculator online

This small and cute bento box from WeeSprout is perfect for kids. Aside from the right capacity and organized interior, it highlights skid-proof silicone sleeves to prevent sliding or slipping due to wet hands or on slippery surfaces.Stainless Steel — Ultra-durable & unbreakable stainless steel bento box; Tall Compartment Dividers — Food stays exactly how you pack it; 8.2 x 6.1 x 2.1 — Fits perfectly in purses, work .

Geometrical Method of Full Cone Fabrication Layout Development is also called Graphical Method of Full Cone Layout Development, in this layout, Method layout markings are developed using direct measuring of the Geometrical shape of Full Cone. This Method is Basic Method for fabrication Layout but it . See more

Numerical Method for Full Cone layout Development is a very faster and time-saving method for layouting, you can calculate the values of layout dimension by solving manually on a scientific calculator or you can use any computerized tool for solving such as MS . See moreWe are providing this example solution Checking Method to you so that you can easily verify your calculated values with some standard . See more

Example:Generate Fabrication Layout Development Markings of Full Cone for Following Sizes: Solution: Step 1: Note Down the Given Data of the Example. Given Data: D = 500 H = 750. Step 2:Calculate Development Radius R R = √ ( H2 + (D/2)2) R = √ ( . See more Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .

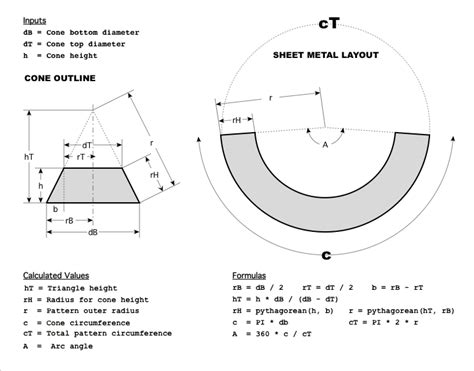

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with .Online calculator for calculating the development of truncated and straight cones will help find the angle of the lateral surface, radius, and arc length of the development. Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.Sheet Metal Cone Layout Calculator - Kzell.com. Enter Finished Cone Dimensions: D = DIAMETER OF LARGE END. D1 = DIAMETER OF SMALL END. H = HEIGHT OF CONE. N = NUMBER OF PLATES.

The calculator computes parameters of a right circular cone or truncated right circular cone development. The picture below illustrates the task. We have the lower base radius, radius of the upper base (in case of a truncated cone), and .

Now to help produce your accurate cone development use this formula: Angle = (D1 x 360) / D2. Where: Angle = the included angle between the outside lines of the main development; D1 = the diameter is of the base of the .Sheet Metal Cone Layout Calculator. Click Here for Cone Instructions ». Enter your inputs below: JOB NAME. D = DIAMETER OF LARGE END. D1 = DIAMETER OF SMALL END. H = HEIGHT OF CONE. N = NUMBER OF .Frustum of a Cone. Draw an elevation view, including the apex point. Profile the base of the elevation view and divide it into 6 equal parts. Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the .

Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is. First you must find the difference between the large and the small Dia. Multiply the large dia. by the vertical height, Divide this product by the difference first obtained large dia and small dia)

1. You know how long your frustum needs to be, how wide you want it at the base and how wide you want it at the shnozzle end. Draw the base of your frustum. A frustum is a portion of a cone, or a cone with the tip chopped off. I have . These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD .20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.Ever wanted to figure out the pattern to cut out a cone shaped object from Sintra, Foam, Worbla or any other material? . Sheet Metal Drawing. Cone Template. Metal Pitcher. Pattern Outer. Sheet Metal Work. Woodstock 1969. Sheet Metal Fabrication. Math Formulas. Patrick Parsley. 1 follower. Comments. No comments yet! Add one to start the .

In this video we will learn how to find concentric cone development with simple school mathematics.Cone layout,Trigonometry formulas tan€= opposite side/adja.Flat Top Cone Calculator. Calculates the measurements for the pattern to construct a flat top cone. Length A (mm) Length B (mm) Length C (mm) Arc Angle = _ (degrees) Radius R1 = _ (mm) Radius R2 = _ (mm) Join my newsletter to keep updated! 💌 .Overlap Normally, the flat pattern dimensions are are exact and dont have any extra material for overlapping the edges. If you want extra material on the edges of the cone then add here. The material is added evenly along the edge. If you enter 0.5" for overlap the shape of the original will be produced on the screen with the addition of red lines offset from each edge by 0.25.

blue box electrical outlet

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt.BLANK DEVELOPMENT For Formed Sheet Metal Parts There are many systems employed by a variety of industries (aircraft, electronics, architectural, automotive, etc.) . The formula for this is SB= .43r + 1.372t r = The radius on the inside curve of the bend. t = The thickness of the sheet or plate 2.000 2.000Development Pattern Construction: CONSTRUCTING DEVELOPMENT SHAPES WITH MATHEMATICS The construction of 3-D models from pieces from flat cardboard or thin sheet metal requires some mathematical and geometrical application. Starting with simple 3-D forms, we can calculate the shape of. Any pitch will work) see Fig.1 The next step would be to add a profile of the fitting to the base.We need to divide the cone up into equal areas and to do this we need to see the base in a true form and the only way to see the base of .

Additionally, the calculator is beneficial for calculating surface development and side development, which is especially important for drawings and creating parts from metal. Our online calculator has built-in formulas, allowing the calculation of these parameters simply by selecting the type of cone and entering the absolute values in the .Pattern Development: Sheet Metal Level 1. Radial Line Pattern Development. 21 Pyramid Any number of sides can be developed with this same method. Draw a plan and elevation view. . the hypotenuse of a cone, outside edge. The slant height is always a true length in the elevation view. The second flat-blank-development example adds the two dimensions (from edge to the apex), and subtracts a bend deduction. . More Than One Sheet Metal Bending Formula. Press brake technicians can use .

Please watch: "Learn Fabrication Layout development of all shapes in by reading Master in Fabrication layout eBook" https://www.youtube.com/watch?v=dzeZCENqM. 'sheet metal cone development formula Grinding Mill China June 19th, 2018 - Learn how to layout a cone in sheet metal Sheetmetalworld com Posts Related to sheet metal cone development formula » pattern roll For Economy Rolling Mill' 'Cone Layout Free download and software reviews CNET June 22nd, 2018 - Cone Layout is a program to unfold a .Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .

For creating a cone from sheet metal or any flat material. Added the function of saving the development of a straight and truncated cone to a DXF file. Export the flat pattern as a dxf file, then you can open it with any CAD program like Acad. You can use the dxf file to cut the sheet on a laser or cnc machine.enter finished cone dimensions: d = diameter of large end: d1 = diameter of small end: h = height of cone: n = number of plates: lr = large layout rad * sr = small layout rad * ang = angle of segment: How to calculate and draw out a Right Cone Development using Pythagoras's Theorem and a Chord Length. Drawn using Autocad 2018. I also have a Lightboard vid.Please watch: "how to make mug drawing in solid work" https://www.youtube.com/watch?v=6Ohq84bfDJ0 --~--THIS VIDEO SHOWING HOW TO DEVELOPMENT CONE USING ANDRO.

I would cut the parts out of sheet metal and roll them up to form the parts. So I need the generic mathematical formula for the intersecting curve for the cylinder, where the formula describes the curved edge when the cylinder is laid flat and then rolled up so that it exactly meets the truncated cone. The cylinder could intersect at any angle.In this comprehensive guide, we will take you through the process of fabricating a sheet metal cone from start to finish. Materials and Tools You'll Need . Before we dive into the fabrication process, let's gather the necessary materials and tools. To fabricate a sheet metal cone, you'll need: Sheet metal (preferably steel, aluminum, or copper) About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

truncated cone template calculator

Yes, it is possible to weld sheet metal with a stick welding machine, but it is the most challenging option due to the aggressive nature of the stick welding process. We would only recommend using a stick welder on sheet metal if you have a very tight budget (and you don’t have access to a TIG or MIG welder) or you are working outdoors (stick .

sheet metal cone development formula|cone template calculator