how is sheet metal bent Bending and Forming. Figure 1: A plate’s grains run parallel to the rolling direction. While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up . I received my 1099-R for making a 401k withdrawl from my former employer. The amount in box 1, however is not the amount I actually received when I got the check ($25,000). The amount reported in box 1, is the amount with the 20% tax I already paid ($31,250).

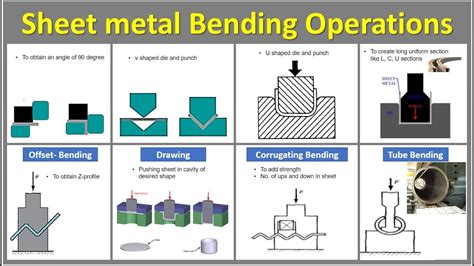

0 · types of bending sheet metal

1 · sheet metal cutting and bending

2 · sheet metal bending near me

3 · sheet metal bending dies

4 · maximum thickness sheet metal bending

5 · hand bending sheet metal

6 · bending tool for sheet metal

7 · bending galvanized sheet metal

What Does a Sheet Metal Mechanic Do? A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet . How sheet metal bends, k factor, bend allowance explained and more. This video includes drawings, animations, formulas and press brake bends. When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some allowance for the bend is taken . Bending and Forming. Figure 1: A plate’s grains run parallel to the rolling direction. While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up .

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. In this video, we'll dive deep into the world of sheet metal bending, covering everything from the basics to essent.

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . IF so, then you can bend the edges as you want. With a 2x4 longer than the metal to be bent, use your skill saw to cut a slot through the length of the board, just a little longer than the piece of metal to be bent. Place the metal into the slot to the point where you want to bend it, then bend it to the angle you want it.

types of bending sheet metal

The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part . Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

This article dives into the essential techniques and precautions for Z and N bending in sheet metal fabrication. You’ll learn about critical procedures, positioning principles, and special processing methods to ensure accurate and efficient results in your metalworking projects. Gain insights into how these bending techniques can enhance your .

Sheet metal bending with a press brake works by aligning and holding the metal to be bent in the press brake tool. Once it is aligned, the press can move down and exert a force onto the metal, forming it into a new shape by producing angles. Press brakes can exert forces well in excess of 100 tons to bend steel upwards of 3 mm thick.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.Welcome to contact with us if you have sheet metal parts want to custom make:Email: [email protected]: +86 13727008794#SheetMetalStamping#MetalStampi. When bending sheet metal, Inventor states the flange as being bent up when inserting bend notes on drawings but the bend line is actually bent down as would be the case on the press brake as the knife presses into the vee. Does anyone know of the BS or ISO standard drawing principle for this notatio. (A press brake is a simple machine employed in sheet metal bending processes, it forms desired bends on the sheet by working to clamp the sheet metal in position for press between the punch and the die) Roll Bending. The roll bending process uses 2, 3, or 4 rollers to shape metal sheets into desired curves. The most common setup is the 3-roll .

Add a double bend to a sheet metal face. On the ribbon, click Sheet Metal tab Create panel Bend. Select a model edge on each sheet metal face. Enter a Bend Radius if it is different from the default for the part. Click the down arrow to select Measure, Show Dimensions, or List Parameters to enter a different value.In sheet metal design, I would not be designing where I would require 15mil tolerance for anything to line up correctly. That's why god invented slotted holes. . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you .Sheet metal bending is the manufacturing process by which most enclosures, electrical boxes, brackets, and components are formed through the use of a machine known as a CNC press brake or (brake press). This technical article explains how fabrication companies bend sheet metal using these types of machines. We hope that after reading this . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) .

Sheet metal bending is a manufacturing process that deforms flat metal sheets into desired shapes with force. The process uses tools like punches and dies. Commonly, laser-cut sheet metals are bent using press brakes or . 3.2 Step Bending Metal Sheet Exceptions. Some of the metal sheets you will not find friendly to work with when it comes to step bending include: 3.2.1 6061 Aluminum. 6061 aluminum is a tampered material. So, it . Ever thought bending sheet metal could be so intricate? Closed bending, a critical technique in sheet metal processing, uses specialized methods to achieve precise, durable bends without needing a professional die. This . Sheet metal bending with a press brake works by aligning and holding the metal to be bent in the press brake tool. Once it is aligned, the press can move down and exert a force onto the metal, forming it into a new shape by producing angles. Press brakes can exert forces well in excess of 100 tons to bend steel upwards of 3 mm thick.

Finally, make sure the sheet is filed down smoothly, because otherwise you may get cracks in the metal. Place Forms and Sheet in Vise: Your form blocks should have the exact shape for bending your metal angle. When you clamp the sheet metal into the vise’s grip, make sure the bend lines on your blocks and sheet match up.

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more.

Welcome to RapidDirect's YouTube channel! In this video, we'll dive deep into the world of sheet metal bending, covering everything from the basics to essent. Bend Allowance Chart. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.The Basics of Sheet Metal. Understanding What Sheet Metal Is. Sheet metal is one of the fundamental materials used in metalworking, and it can be cut and bent into various shapes. Manufacturers fabricate countless everyday objects from sheet metal, using materials like steel, aluminum, brass, and even gold for specific applications.

need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication, Installation. Welding, HVAC, Roofing, commercial kitchen stainless, home renovation, sheet metal art & etc. ! This doesn’t just work with thin sheet metal. You can use this method to bend material that would make a sheet metal bending brake cry. So what is this 2-step diy bending process that can do the job of a press brake? Here’s the secret: Step 1 – Make relief cuts in your part along the line you want to bend. Step 2 – Bend. That’s it, no .

Sheet metal bending is the manufacturing process by which most enclosures, electrical boxes, brackets and components are formed through the use of a machine known as a CNC pressbrake (or sometimes known as a brake press). This technical article explains how fabrication companies bend sheet metal using these types of machines. As shown in Figure 2-2, the deformation grid of the sheet metal’s side view before and after bending is illustrated. Looking at Figure 2-2, it is evident that in the flat portion of the sheet metal, the grid maintains its pre-bend state, with significant changes only within the range of the central bending angle α.. This indicates that the bending deformation primarily occurs in .

stainless steel hood under cabinet

stainless steel jockey box coil

From the looks of the wiring to the Positive battery post Farmer John seems to have done his worst; The link wire seems to be Orange 10 gauge which seems to be .

how is sheet metal bent|sheet metal cutting and bending