lancing operation in sheet metal SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. . But 18 gauge cold roll is just the sweetest stuff for fabricating pans. We got 4 x 10' sheets for the shop I work at on the last purchase and I don't know the price. But it could be high and still beat the alternatives.

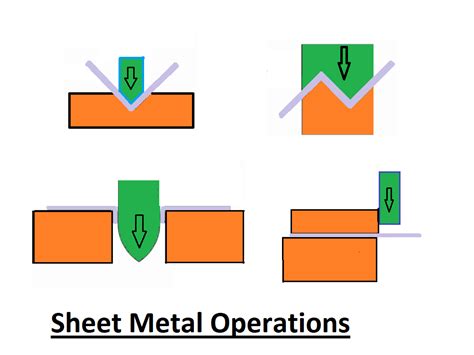

0 · sheet metal operations with diagrams

1 · sheet metal operation pdf

2 · sheet metal bending process pdf

3 · restrike process in sheet metal

4 · forming operation in sheet metal

5 · difference between blanking and punching

6 · cutting clearance for sheet metal

7 · blanking operation in sheet metal

$209.99

SolidWorks II Sheet Metal II Lancing Operations, Lancing Features & Lancing Tool Design In this video, I am going to explain about Lancing operations in Sheet Metal , create Lancin.

Learn about different cutting processes in sheet metal stamping, including lancing, which slices or slits the metal without creating a slug. Lancing can save material and eliminate scrap removal systems.

sheet metal operations with diagrams

sheet metal operation pdf

Learn about different types of sheet metal cutting processes, such as shearing, blanking, punching, slotting, nibbling, perforation, piercing, notching, trimming, and deburring. Lancing is a type of punching operation that cuts and bends . This video demonstrates the working of Lancing operation.SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. .Sheet metal operations are usually carried by using punch and die. The mechanism of operation of punch and die is shown in Figure 6.2. Die is having the negative shape of the contour and punch has the positive contour of the shape .

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is . There are several punching procedures based on the punched-out geometry, such as piercing, lancing, notching, nibbling, and perforating. 3. Broaching is a standard sheet metal cutting technique in which a tool with . Sheet metal piercing using high quality piercing punches and oil. Learn how to improve tool life, increase productivity and solutions to common problems. Skip to content. . Lancing is a partial cutting operation where . Zip Tech lance and form tool fabricates snaps to join metal parts together without time consuming and labor-intensive welding and grinding operations, spot welding or other fastening methods. Available in any style NC .

SHEET METAL OPERATIONS. SHEET METALWORKING Cutting and forming thin sheets of metal usually performed as cold working Sheet metal = 0.4 (1/64) to 6 mm (1/4in) . LANCING OPERATION. Maximum force, P required to be exerted by the punch to shear out a blank from the sheet can be Lancing is a process in a metal sheet in which metal is cutting a sheet of metal through part of its length and then bending the cut portion. . More Sheet Metal Operation Questions . Q1.Load Vs Displacement curve shown in the following figure pertains to Q2. For full video, please click the link below https://youtu.be/M9eO1YMNn3A

Punching is an operation that involves punching holes or other more complex shapes to remove material from metal sheets. The removed material ends up as scrap which is the complete opposite of blanking wherein the punched-out shapes are the product. There are a variety of different punching operations available which we’ll cover shortly. #sscje #mechanical #gearinstitute Click here to download our apphttps://edumartin.page.link/jLFrJoin telegram channelhttps://t.me/gearinstituteSSC JE / RRB J. Sheet Metal Lancing Operation - Louver tool Design in Solidworks Sheet Metal Lancing Operation - Louver tool Design in Solidworks / Loading . Custome lance.SLDPRT. sldprt. October 5th, 2018 Custome lance.SLDFTP. sldftp. October 5th, 2018 2018-09-30_20-57-30.png. png. October 5th, 2018 louv1a.jpg .

In this video, I am going to explain about creating different types of Louver in SolidWorks - Sheet Metal Module. Also, I am going to explain, how to creat. Subject - Manufacturing Processes, MetallurgyChapter - Difference between Blanking, Piercing, Punching, Lancing, Notching Process, Sheet metal WorkingTimecod.Some examples of products that use sheet metal are car bodies, airplane wings, kitchen utensils, and metal roofs. Sheet metal stock is specified by the dimensions of the sheet, the type of material, and the gauge. The gauge is a measure of the thickness of the sheet metal, and it varies depending on the material. For example, a 14-gauge steel . Sheet metal punching operation. Punching is a straightforward way of cutting sheet metal. A punching machine is used to create relatively small parts of different shapes. It involves using a punching press, which exerts a force on the sheet metal placed in the punching die to create the part of the desired shape. . Lancing: With a single hit .

sheet metal bending process pdf

In sheet metal, this question always creates some confusion. What is the difference between punching blanking and piercing? Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. 2. Introduction: Punching and blanking processes are sheet metal forming processes. In these two processes a finite volume of metal from a sheet is removed by using die and punch. The shape and size of the portion removed depends on the geometry of die and punch. Also the operation cost and time depends on die and punch design. Hi Friends,In this video you will learn Different types of Cutting operation in sheet metal | Sheet metal cutting operationsShearingCutoff Parting offBlankin.Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force.In this process, the piece removed, called the blank, is not scrap but rather the desired .

Lancing is a unique kind of sheet metal operation in which we partially cut some portion of the sheet metal but do not remove it completely. The partially cut parts remain attached to the sheet metal in bending to give the sheet metal a desirable shape. Sheet metal cutting is a vital operation in the fabrication industry, with many processes used to meet varied needs and material types. The chosen process has a considerable impact on the ultimate product's quality, efficiency, and cost-effectiveness. . Lancing: A single strike is used to shear and bend a section of a sheet metal component to .

Table 1 Sheet metal operations with shearing process Category Operations For creating blanks Blanking, ne blanking, cuto . For combination of cutting and non-cutting Lancing, louvering For nishing Trimming, shaving. Transactions of the Indian National Academy of Engineering (2023) 8:509–534 511 123 mechanisms that control the initiation and .

Systems and methods of conducting a time-marching simulation of manufacturing a sheet metal part that requires progressive lancing operation (PLO) are disclosed. The time-marching simulation is conducted with a connection-separation scheme for nodes along the lancing route to ensure a smooth timely separation of a lancing cut. The scheme includes creating a set of . SHEET METAL WORKING OPERATIONS AND APPLICATIONSDuring lancing operation sufficient degree of clearance should be maintained around the lance feature as the punch and die will need some degree of clearance around the feature in order to hold . Also, the ratio of return flange height to the sheet metal thickness should be greater than or equal to 4. Where, H = Return flange height D = Open .Systems and methods of conducting a time-marching simulation of manufacturing a sheet metal part that requires progressive lancing operation (PLO) are disclosed. The time-marching simulation is conducted with a connection-separation scheme for nodes along the lancing route to ensure a smooth timely separation of a lancing cut. The scheme includes creating a set of .

Sheet metal operations are usually carried by using punch and die. The mechanism of operation of punch and die is shown in Figure 6.2. . 6.3.10 Lancing Lancing is the operation of cutting a sheet of metal through part of its length and bending the cut portion. Lancing is shown in Figure 6.11. Figure 6.11 Lancing. 6.4 Mechanism of Blanking. Bending operation in sheet metal forming has been extensively used in manufacturing technology for mass production especially in automotive industry as one of the tools for shaping into a desired . (b) Examples of various die-cutting operations on sheet metal. Lancing involves slitting the sheet to form a tab. FIGURE 5 (a) Comparison of sheared edges produced by conventional (left) and by fine blanking (right) techniques. (b) Schematic illustration of one setup for fine blanking. FIGURE 6 Slitting with rotary knives.

Sheet Metal Operations, Blanking, Notching, Drawing, Punching, Perforating, Nibbling, Bending, Embossing

restrike process in sheet metal

forming operation in sheet metal

difference between blanking and punching

cutting clearance for sheet metal

Tormach makes CNC machines and automation tools that offer precision across a range of materials, without the need for expensive industrial three-phase power. Our machines cut wood, plastics, aluminum, steel, and titanium.

lancing operation in sheet metal|sheet metal operations with diagrams