tolerancing sheet metal parts Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from . Metal detecting around an old house built in 1951. I made an unexpected discovery that predates the house by nearly 100 years!

0 · steel thickness tolerance chart

1 · standard sheet metal tolerances chart

2 · sheet thickness tolerance chart

3 · sheet metal tolerances pdf

4 · sheet metal tolerances chart

5 · sheet metal thickness tolerance chart

6 · sheet metal gauge tolerance chart

7 · sheet metal dimensioning standards

Experience top-notch metal fabrication from a leading manufacturer. Explore our state-of-the-art equipment, diverse services, and custom finishing options. Full Service Metal Fabrication | .

When choosing a manufacturer for your sheet metal parts, the term tolerance often comes up. Everyone wants their parts to be exact replicas of . The first dimension, 11.20±0.25, has a tolerance equivalent to approximately ±.010 inches. This dimension alone is challenging – our standard tolerance sheet indicates that a . Sheet metal tolerancing is a bit more complicated because of the fundamental differences in raw materials and manufacturing processes. Let’s . What Is Sheet Metal Tolerance? Sheet metal tolerance refers to the specified range that allows for deviations in the design sizes of parts. This range defines the upper and .

Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from .

Discover the essentials of Sheet Metal Tolerances with our in-depth guide covering dimensional, geometric, and material variations. Sheet metal tolerances help manufacturers align components and ensure optimal performance. Tolerancing is crucial for most industries. Learn why precision matters for sheet metal fabrication.

The acceptable difference from specified dimensions in fabricated parts is known as sheet metal tolerances. It is the permissible variation between actual and intended . Let’s explore the definition of tolerancing, the difference between precision machining and sheet metal fabrication tolerances, and how to rectify the common problem of overtolerancing parts. Tolerancing refers to defining .

steel thickness tolerance chart

Sheet metal parts are made from a single metal sheet by punching, cutting, stamping, and/or bending and are known for their end-use durability. But there are still many important design-for-manufacturability issues to consider. . This whitepaper helps describe a set of broad guidelines that you can use while specifying tolerances for your sheet metal parts drawing(s). Essentially, these are in place due to practical limitations of sheet metal .Tolerances are the acceptable range of variations in the dimensions of sheet metal parts that we manufacture. Tolerances are a guarantee that our parts will fit and perform as intended for your projects, just as they did for Jack Garcia and .

Fabricating sheet metal provides durable and accurate components for countless industries. However, many sectors require tight tolerances to ensure multi-faceted compatibility, successful functional testing, and standardized .

Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).

In sheet metal design, I would not be designing where I would require 15mil tolerance for anything to line up correctly. That's why god invented slotted holes. . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you . Industry Standards for Sheet Metal Tolerances. Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768. ISO 2768 is an important standard for general tolerances in sheet metal fabrication.Abstract: The dimensional accuracy of bent sheet metal parts is influenced by many factors and possible sources of inaccuracy such as the sheet material, machine, and . successful applications of the methods mentioned above on computer-aided tolerancing for sheet metal bending. In this paper, tolerance verification for sheet metal bending is .For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose.

The standard is organized in nine parts, with details of the geometrical characteristics in parts five through nine. Need an Overview of the ASME Y14.5 2009 and 2018 Standard? Check out our free ASME Y14.5 2009 vs. 2018 Comparison Chart These tolerance constraints apply not only when attaching two sheet metal parts together, but also when attaching sheet metal to other components such as weldments, or plastic/structural foam skins. Therefore when possible you should have any high tolerance alignment occur within one plane of sheet metal, strength can come from bends and .11. To dimension and tolerance a fixture for simulate datum features for inspection. 12. How to apply and fixture “step datums”. 13. How to use multiple slot centerplanes to create a datum reference frame. 14. The most popular and effective datum scheme for .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts. Bending Tolerances . Bends (and their corresponding tolerances) either pertain to a controlled dimension, or an uncontrolled .

utilized in prototyping and production parts. Well suited for intricate details and irregular contours, additional economies can be obtained through the nesting of parts when laser cutting. Tolerances – The feature to feature tolerance on for the laser cutter is . The most popular and effective datum scheme for tolerancing sheet metal panels. . -Common Misconceptions-Free State Variation in Sheet Metal Parts-Specifying Restrained State Inspection-Fixturing Sheet Metal Parts-Profile ALL OVER Controls and What They Mean . Upvote 0 Downvote. Dec 4, 2018 #11 drawoh Mechanical. Oct 1, 2002General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . CNC Machining, Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Table 6 - General Tolerances on Symmetry Table 7 - General .EF-001 Recommended Default Sheet Metal Tolerances Rev A Recommended Default Sheet Metal Tolerances Default Tolerances (Millimeters) DIM Tolerance Description A ± 0.13 Sheared Edge to Hole B ± 0.13 2 Holes on One Surface . Noted dimensions are for parts within a 12” envelope * Dimensions D, E and H are not recommended forms of dimensioning .

Sheet metal parts must be processed as precisely and distortion-free as possible. This is done so that final products can be assembled efficiently. Welding robots, in particular, require tight tolerances. Precise parts are obtained by leveling the .

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Sheet metal parts and designs generally incorporate a number of standard design features that improve part utility, strength, rigidity or other properties based on the .

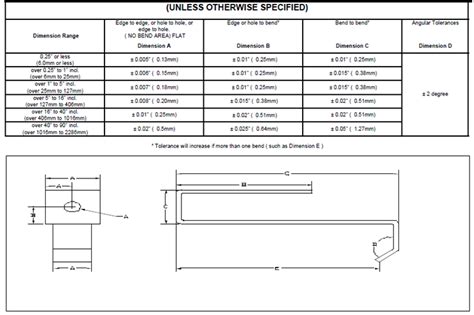

tolerances.Sheet metal.Process planning 1 Introduction Sheet metal forming (SMF) is one of the most common manufacturing methods for metal parts and is used widely in industries [99]. As in assembly or metal removal processes, design and process tolerances play an important role with respect to functionality and cost. However,GENERAL DIMENSIONAL TOLERANCES FOR SHEET METAL FORMED PARTS. (UNLESS OTHERWISE SPECIFIED) Dimension Range Dimension A Dimension B Dimension C ± 2 degree ± 0.01" ( 0.25mm) ± 0.015" ( 0.38mm) ± 0.015" ( 0.38mm) ± 0.025" ( 0.64mm) . tolerance sheet metal.xls Author: Rick Slocum Composite parts are characterised by high strength-to-weight ratio. This high ratio is one of the biggest contributions of high stress during their assembly processes. The other difficulty of composite assemblies is that these parts are also brittle (not as ductile as sheet-metal parts).

There are astm standards for sheet metal manufacturers that define the mechanical and physical properties limits for product coming from a rolling mill - where your sheet metal is coming from. From Working in a sheet metal penny for past 10 years I'd say . 5mm over 200mm flatness will be difficulty to achieve unless you have a specially agreed .Leveled sheet metal parts enable assemblies with tighter tolerances. These residual stresses cannot be seen and are difficult to measure. It is therefore important to eliminate them as reliably as possible. In the case of sheet metal and sheet metal parts, leveling helps here. This applies both to the starting material and to sheet metal parts .

Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts. Standard Tolerances For Perforated Sheet Metal. Usually, choosing material thickness is one of the first steps a designer takes when starting a project. We work with nominal thicknesses, so it's important to know the thickness tolerance on the material you chose . MBN 11011: Geometric Product Specification -Geometric Dimensioning and Tolerancing, Company standard, 2010. [22] Zheng, H., Litwa, F. et al, DoE-based Tolerance Analysis for Sheet Metal Parts considering Manufacturing Processes, International Conference on “New Developments in Sheet Metal Forming†, 2020, 71-81. [23]Press Working Parts Tol - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document outlines general dimensional tolerances for parts formed from sheet metal by press working. It establishes three tolerance classes - PTA, PTB, and PTC - for punching, bending, and deep drawing dimensions. Tolerance class PTA allows for the smallest . Sheet Metal Fabrication: Sheet metal parts are typically held to tolerances governed by the ISO 2768-1 standard, which defines acceptable deviations in flatness, angles, and radii. Manufacturers often aim for a balance between achieving tight tolerances and maintaining the cost-effectiveness of production.

horizontal electrical box for vertical outdoor lights

hornady tripoint lock box steel black

Each LOCATOR® male processing package contains: Stainless steel denture cap and black processing male. Clear nylon cap. Pink medium retention cap. Blue light retention cap. Block-out spacer. ZEST® metal housings for connecting to .

tolerancing sheet metal parts|sheet metal gauge tolerance chart