electrical panel box obstruction from open door requirements It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the .

Just tell the HO or inspector that its part of the listing of the light. These boxes are so small you can't put more than two NM cables in them like you could with a traditional junction box.

0 · panel door clearance requirements

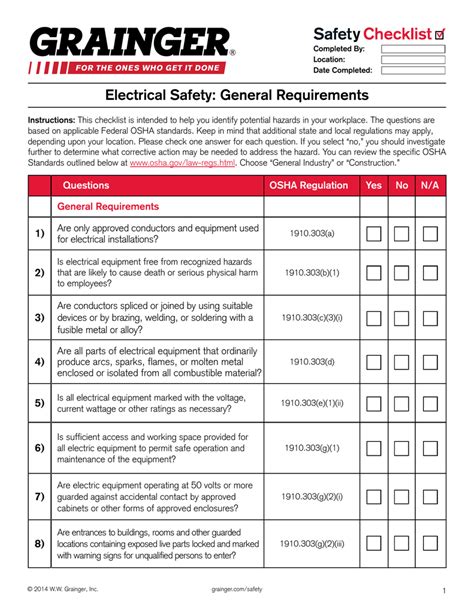

1 · osha outdoor electrical installation requirements

2 · osha electrical panel clearance requirements

3 · electrical panel width requirements

4 · electrical panel opening requirements

5 · electrical equipment door opening requirements

6 · electrical door clearance requirements

7 · building code electrical panel clearance

Learn how to properly wire a lighting junction box for safe and efficient electrical connections. Step-by-step guide for professional results.

In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.The site is secure. The https:// ensures that you are connecting to the official website .

washdown electrical enclosures

The site is secure. The https:// ensures that you are connecting to the official website .In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is .Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.

It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the .

waterproof box electrical

The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the . The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. . OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed .

warped sheet metal

And, if the panel does have a door, then it must be openable to 90º (perpendicular to face of box), per NEC 110.26 (A) (2). So a panel without a dead front is a code safety .

In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.The 3 foot requirement for electrical panel clearances is the most important one to follow. The panel should be accessible and have enough room in front of it so that an electrician can open the door and work safely. This area needs to remain clear at all times.In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is situated in a space with limited access:Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.

It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the minimum for safety.

The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels.

When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26. The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. All electric equipment installed, modified or repaired after March 1972 must comply with the .

panel door clearance requirements

osha outdoor electrical installation requirements

OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed Access: Electrical panels must be accessible at . And, if the panel does have a door, then it must be openable to 90º (perpendicular to face of box), per NEC 110.26 (A) (2). So a panel without a dead front is a code safety violation, but a panel without a door may—or may not—be.

In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.

osha electrical panel clearance requirements

The 3 foot requirement for electrical panel clearances is the most important one to follow. The panel should be accessible and have enough room in front of it so that an electrician can open the door and work safely. This area needs to remain clear at all times.In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is situated in a space with limited access:Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.

It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the minimum for safety.

The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. All electric equipment installed, modified or repaired after March 1972 must comply with the . OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed Access: Electrical panels must be accessible at .

waterloo steel cabinets

wardrobe box metal bar

If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

electrical panel box obstruction from open door requirements|building code electrical panel clearance