4 axis cnc milling service production Elimold’s high-precision machining center library of four-axis CNC machines can provide five-sided machining of complex parts, reducing part handling and machine setup, resulting in . The easiest way to upgrade an ungrounded 120V receptacle to get ground protection is to replace it with a GFCI outlet. This doesn't turn an ungrounded outlet into a grounded outlet, but it does provide protection against shock. A GFCI outlet installation does not protect equipment from power surges.

0 · what is 4 axis cnc

1 · hobby 4 axis cnc machine

2 · cnc 4th axis for sale

3 · 4th axis rotary cnc

4 · 4 axis hobby cnc

5 · 4 axis desktop cnc mill

6 · 4 axis cnc mill cost

7 · 4 axis cnc for sale

Yes, steel wool comes in varying grades of coarseness. Coarse steel wool is best for heavy-duty work, while fine steel wool is ideal for gentle scrubbing to avoid scratches.

Elimold’s high-precision machining center library of four-axis CNC machines can provide five-sided machining of complex parts, reducing part handling and machine setup, resulting in .C&H Machine’s 4 Axis Milling services are ideal for machining parts and components that require close tolerances. A single setup can process dimensional information and designs from multiple datum sets.

A 4-axis CNC machining service factory specializes in providing high-quality machining services that cater to industries such as aerospace, automotive, electronics, and .DEK's 4 Axis CNC milling service is the best solution for projects requiring tighter tolerances – no minimum order quantity is required. We can provide faster and more efficient production with our 4 axis CNC milling equipment. The fourth .

Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.Elimold’s high-precision machining center library of four-axis CNC machines can provide five-sided machining of complex parts, reducing part handling and machine setup, resulting in increased accuracy, faster turnaround and lower costs for CNC machined parts.C&H Machine’s 4 Axis Milling services are ideal for machining parts and components that require close tolerances. A single setup can process dimensional information and designs from multiple datum sets. A 4-axis CNC machining service factory specializes in providing high-quality machining services that cater to industries such as aerospace, automotive, electronics, and medical equipment, where complex parts are often required.

RDL Machine offers full-service CNC machining of various materials to meet specific needs for your project. Our CNC mills can hold critical dimensions and extremely tight tolerances to further ensure that exact specifications are met.

DEK's 4 Axis CNC milling service is the best solution for projects requiring tighter tolerances – no minimum order quantity is required. We can provide faster and more efficient production with our 4 axis CNC milling equipment. The fourth axis provides more flexibility in machining complex shapes and features.

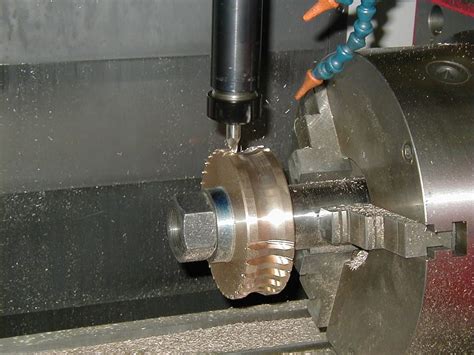

Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.Specializing in 4 Axis CNC machining to achieve greater consistency for parts with exceptional versatility, reliable, efficient, and fast production. What is 4-Axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. 4-axis CNC machining facilitates continuous machining from different angles without manually repositioning and realigning the workpiece. Hence, it reduces the overall time for producing CNC parts. Get your parts into production today! Develop Your Advantage in the Industry – Dive into the Precision of Metal CNC Machining Today!We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.

4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the manufacturing process.Elimold’s high-precision machining center library of four-axis CNC machines can provide five-sided machining of complex parts, reducing part handling and machine setup, resulting in increased accuracy, faster turnaround and lower costs for CNC machined parts.C&H Machine’s 4 Axis Milling services are ideal for machining parts and components that require close tolerances. A single setup can process dimensional information and designs from multiple datum sets. A 4-axis CNC machining service factory specializes in providing high-quality machining services that cater to industries such as aerospace, automotive, electronics, and medical equipment, where complex parts are often required.

RDL Machine offers full-service CNC machining of various materials to meet specific needs for your project. Our CNC mills can hold critical dimensions and extremely tight tolerances to further ensure that exact specifications are met.DEK's 4 Axis CNC milling service is the best solution for projects requiring tighter tolerances – no minimum order quantity is required. We can provide faster and more efficient production with our 4 axis CNC milling equipment. The fourth axis provides more flexibility in machining complex shapes and features.Here is a guide to 4 axis CNC machining: its types, functions, anatomy, pros and cons, and difference between 3- and 5-axis CNC machining.

Specializing in 4 Axis CNC machining to achieve greater consistency for parts with exceptional versatility, reliable, efficient, and fast production. What is 4-Axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. 4-axis CNC machining facilitates continuous machining from different angles without manually repositioning and realigning the workpiece. Hence, it reduces the overall time for producing CNC parts. Get your parts into production today! Develop Your Advantage in the Industry – Dive into the Precision of Metal CNC Machining Today!We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.

what is 4 axis cnc

hobby 4 axis cnc machine

cnc 4th axis for sale

4th axis rotary cnc

4 axis hobby cnc

At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, CNC machines follow programmed instructions to execute precise machining tasks.

4 axis cnc milling service production|what is 4 axis cnc