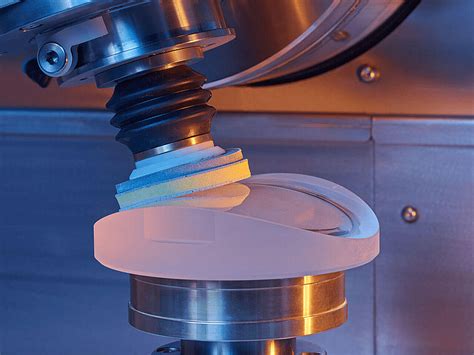

cnc machine polishing parts What surface finishes are available for CNC machining? You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of . Now is the time to address some of the most common issues I’ve received from people looking for a welder for auto body work. See more

0 · polishing tools for cnc mill

1 · mechanical polishing process

2 · deburring brush for cnc machine

3 · cnc polishing tool

4 · cnc machine polishing tools

5 · cnc deburring brushes for aluminum

6 · best paint for cnc mill

7 · aluminum wheel polishing pads factories

Unlike traditional prototyping methods, CNC prototype machining offers unparalleled precision and repeatability. The process involves the removal of material from a solid block, resulting in prototypes that closely mimic the final product in terms of form and function.

polishing tools for cnc mill

This article discusses helpful tips to ensure that your CNC machined parts have the best CNC machining surface finishes possible. Electrical and electrochemical finishing processes offer unique advantages, including the ability to deposit metals or alloys onto surfaces, polish to a high luster, and create protective or functional coatings that significantly .

What surface finishes are available for CNC machining? You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of .

sheet metal local 16 wages

Learn about the surface finishing options for CNC parts, from anodizing and Chem film or Alodine™ to zinc plating and electropolishing. This article discusses helpful tips to ensure that your CNC machined parts have the best CNC machining surface finishes possible. Electrical and electrochemical finishing processes offer unique advantages, including the ability to deposit metals or alloys onto surfaces, polish to a high luster, and create protective or functional coatings that significantly extend the life of CNC machined parts.What surface finishes are available for CNC machining? You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish CNC machined parts, and how to select the best methods for your applications.

In most CNC usages, lapping machines are high-precision units and produce a very fine and consistent surface, free of even microscopic imperfections. Although machining lapping usually produces a uniformly smooth and flat surface, it can also produce concave and convex surfaces. At American Micro Industries, we are quality driven and ready to customize parts for various utilizations. Whether you’re adhering to tight dimensional tolerances and smooth finishes or require additional corrosion and wear resistance, our surface finishes for CNC machining can produce what you need. What are Surface Finishes?

Polishing aluminum CNC parts involves careful steps to achieve a smooth and reflective finish while preserving the precision machined components. Here's a guide on how to effectively polish aluminum CNC parts: Learn the best practices for finishing your CNC parts with our beginner's guide to CNC part finishing. Get the perfect finish every time!

This article discusses the techniques, considerations, and tips to help you achieve superior surface finishes in CNC machining. 1. Geometric or Ideal Finish. 2. Natural Finish. 1. Grinding. 2. Reaming. 3. Burnishing. 4. Finish Boring. 5. Lapping. 6. Honing. 7. Hydrohoning. 8. Superfinishing. 9. Polishing. 10. Buffing. 11. Shot or Grit Blasting. 12. Polishing. There are several different types of polishing to finish off a machined plastic part. Here are a few of the most common methods: Vibratory Polishing: This method uses rotating or vibrating tumblers along with a variety of media to deburr, remove tooling marks and polish parts. It is convenient for large bulk items that need polishing. Learn about the surface finishing options for CNC parts, from anodizing and Chem film or Alodine™ to zinc plating and electropolishing. This article discusses helpful tips to ensure that your CNC machined parts have the best CNC machining surface finishes possible.

Electrical and electrochemical finishing processes offer unique advantages, including the ability to deposit metals or alloys onto surfaces, polish to a high luster, and create protective or functional coatings that significantly extend the life of CNC machined parts.What surface finishes are available for CNC machining? You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish CNC machined parts, and how to select the best methods for your applications.

In most CNC usages, lapping machines are high-precision units and produce a very fine and consistent surface, free of even microscopic imperfections. Although machining lapping usually produces a uniformly smooth and flat surface, it can also produce concave and convex surfaces.

At American Micro Industries, we are quality driven and ready to customize parts for various utilizations. Whether you’re adhering to tight dimensional tolerances and smooth finishes or require additional corrosion and wear resistance, our surface finishes for CNC machining can produce what you need. What are Surface Finishes?

Polishing aluminum CNC parts involves careful steps to achieve a smooth and reflective finish while preserving the precision machined components. Here's a guide on how to effectively polish aluminum CNC parts: Learn the best practices for finishing your CNC parts with our beginner's guide to CNC part finishing. Get the perfect finish every time! This article discusses the techniques, considerations, and tips to help you achieve superior surface finishes in CNC machining. 1. Geometric or Ideal Finish. 2. Natural Finish. 1. Grinding. 2. Reaming. 3. Burnishing. 4. Finish Boring. 5. Lapping. 6. Honing. 7. Hydrohoning. 8. Superfinishing. 9. Polishing. 10. Buffing. 11. Shot or Grit Blasting. 12.

sheet metal laser cutting in stock

Have you been wondering, “what would my house look like with a steel roof”? Now you can try before you buy! In just a few steps, you can see how a sleek, modern new Hy-Grade Steel Roof can enhance the look of your home.

cnc machine polishing parts|deburring brush for cnc machine