building a cnc machine where do i start In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your . Junction boxes are typically located in walls and ceilings, but they must be accessible without any tools in order to comply with safety regulations. They can be mounted directly on the wall or ceiling, or they can be installed using a mounting bracket.

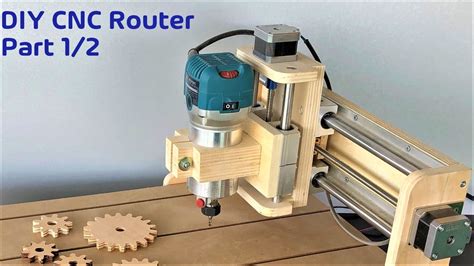

0 · homemade cnc router machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · build your own cnc router

4 · build your own cnc mill

5 · build your own cnc machine

6 · build your own cnc kit

7 · build your own cnc

I removed an older outlet in a single gang metal box and it had electrical taped wrapped around it, covering the terminals. I feel like I've seen that before and after googling, it seemed like it was optional, depending on code.

homemade cnc router machine

Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you . Although he certainly achieves that, more or less, automating the classic toy is just the hook for a thorough lesson in CNC machine building .

To begin building your CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with an extensive list and guide you on where to find affordable options or .

metal decorative edge scissors for fabric

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your .Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, . Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page? Why Build Your Own CNC Machine? Building a DIY CNC router machine can be more beneficial . If this sounds like you, never fear—the team at Scan2CAD is here to help. We’re here to provide handy tips on building a CNC machine. We’ll include some great options for CNC kits, as well as details and resources .

Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your .There are several ways to start your CNC project but before you start consider the following: How big should the machine be (work area X-,Y,C-axis)? Do i have a solid set of plans to build from? What materials do I want to be able to .

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?

Although he certainly achieves that, more or less, automating the classic toy is just the hook for a thorough lesson in CNC machine building starting with the basics.To begin building your CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with an extensive list and guide you on where to find affordable options or repurpose items you may already have.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field.Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more.

Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page? Why Build Your Own CNC Machine? Building a DIY CNC router machine can be more beneficial than purchasing one. Let's run through some of the reasons: 1. Save Money. If this sounds like you, never fear—the team at Scan2CAD is here to help. We’re here to provide handy tips on building a CNC machine. We’ll include some great options for CNC kits, as well as details and resources covering how to build your own CNC machine from scratch. Let’s get started!

Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. Chapter 1: Understanding CNC Machines. Introduction to CNC machines.

There are several ways to start your CNC project but before you start consider the following: How big should the machine be (work area X-,Y,C-axis)? Do i have a solid set of plans to build from? What materials do I want to be able to process? Do I have the necessary equipment/tools to make it? What materials should be used to build the machine?

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing? Although he certainly achieves that, more or less, automating the classic toy is just the hook for a thorough lesson in CNC machine building starting with the basics.To begin building your CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with an extensive list and guide you on where to find affordable options or repurpose items you may already have.

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field.Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more. Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page? Why Build Your Own CNC Machine? Building a DIY CNC router machine can be more beneficial than purchasing one. Let's run through some of the reasons: 1. Save Money.

If this sounds like you, never fear—the team at Scan2CAD is here to help. We’re here to provide handy tips on building a CNC machine. We’ll include some great options for CNC kits, as well as details and resources covering how to build your own CNC machine from scratch. Let’s get started!Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. Chapter 1: Understanding CNC Machines. Introduction to CNC machines.

metal decorative holiday houses for sale tealight holder

In sum, houses are built stick-frame because of efficiency and sustainability. Cost and workability. I only ever see (in Canada) steel moment frames and the odd steel post or beam used. Moment frames are often now replaced with osb sheer panels. And it seems like steel is usually on specified when a wood post or beam would be larger than desired.

building a cnc machine where do i start|build your own cnc mill