application of cnc machines in mould manufacturing Through the introduction of high-speed CNC machining technology, composite CNC machining technology and CNC EDM technology, its potential in improving manufacturing efficiency, reducing costs and improving product quality is deeply analyzed in . Find Enclosure electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

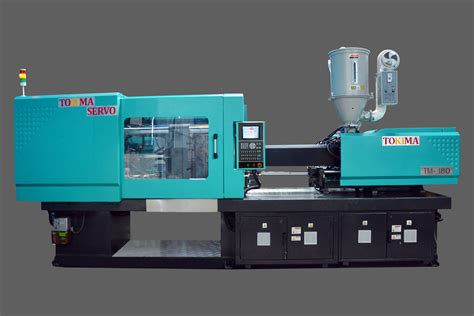

0 · cnc plastic injection moulding machine

1 · cnc moulding machine

2 · cnc mold making

3 · cnc machining vs injection molding

4 · cnc machine for mold making

5 · cnc injection molding machine

6 · cnc injection molding

7 · 5 axis cnc milling machine

Apresentamos-lhe o nosso torno CNC líder em vendas. Se procura uma máquina CNC de alto desempenho, potente e fiável, a série TA oferece 3 modelos (Z400, Z640 e Z1100) com múltiplas opções de configuração. Tornos CNC de bancada prismática incorporando uma torreta com motor incorporado de 12.000 rpm e cabeçotes integrados e .

CNC Machining for Tooling: CNC technology is employed to create the various tools and dies needed in mold manufacturing. This includes cutting, shaping, and finishing tool steel or other .Thanks to CNC machines, this precision has become not just possible but standard practice in the die and mould industry. In this post, we'll explore eight key applications of CNC machines in die and mould manufacturing, shedding light on why these cutting-edge tools are vital in this sector.CNC Machining for Tooling: CNC technology is employed to create the various tools and dies needed in mold manufacturing. This includes cutting, shaping, and finishing tool steel or other materials used for the production of molds.

cnc chuck manufacturers in india

Through the introduction of high-speed CNC machining technology, composite CNC machining technology and CNC EDM technology, its potential in improving manufacturing efficiency, reducing costs and improving product quality is deeply analyzed in .CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens .In this blog post, we'll explore the relevant applications of CNC machines in mould manufacturing, delving into its benefits, how it measures up against traditional methods, and some of the best practices in utilizing this advanced machinery.In this increasingly digital age, CNC machines have revolutionized the manufacturing industry with their precision and efficiency. Understanding how to effectively create molds using CNC machines is crucial for producing high-quality products with intricate designs.

In short, the application of CNC machining technology not only improves the efficiency of mechanical mold manufacturing but also improves the performance of mold products. The automated processing process reduces human interference and ensures the stability of mold quality and accuracy.

When comes of mold making, we usually use cnc router machine to make because it is with high precision and productivity. And for the mold materials, the most common we use is tooling board. What is Tooling Board? Tooling board, also known as modeling board and machinable slab are used for producing master models and prototype tooling. The application of CNC machining technology in the mold manufacturing process 2.1 There are various kinds of CNC machines used in the process of mold processing, according to the actual production needs of the type of mold to select the machine, reduce production costs and fully classify the processing mold.CNC milling machines are highly accurate and can produce complex shapes and intricate parts to tight tolerances. It provides improved efficiency and consistency in the manufacturing process, reduces errors and waste, and allows the production of customized products at a faster rate.

Thanks to CNC machines, this precision has become not just possible but standard practice in the die and mould industry. In this post, we'll explore eight key applications of CNC machines in die and mould manufacturing, shedding light on why these cutting-edge tools are vital in this sector.CNC Machining for Tooling: CNC technology is employed to create the various tools and dies needed in mold manufacturing. This includes cutting, shaping, and finishing tool steel or other materials used for the production of molds.Through the introduction of high-speed CNC machining technology, composite CNC machining technology and CNC EDM technology, its potential in improving manufacturing efficiency, reducing costs and improving product quality is deeply analyzed in .CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens .

In this blog post, we'll explore the relevant applications of CNC machines in mould manufacturing, delving into its benefits, how it measures up against traditional methods, and some of the best practices in utilizing this advanced machinery.

In this increasingly digital age, CNC machines have revolutionized the manufacturing industry with their precision and efficiency. Understanding how to effectively create molds using CNC machines is crucial for producing high-quality products with intricate designs. In short, the application of CNC machining technology not only improves the efficiency of mechanical mold manufacturing but also improves the performance of mold products. The automated processing process reduces human interference and ensures the stability of mold quality and accuracy. When comes of mold making, we usually use cnc router machine to make because it is with high precision and productivity. And for the mold materials, the most common we use is tooling board. What is Tooling Board? Tooling board, also known as modeling board and machinable slab are used for producing master models and prototype tooling.

The application of CNC machining technology in the mold manufacturing process 2.1 There are various kinds of CNC machines used in the process of mold processing, according to the actual production needs of the type of mold to select the machine, reduce production costs and fully classify the processing mold.

cnc car parts supplier

cnc plastic injection moulding machine

cnc burr manufacturers

cnc moulding machine

cnc mold making

Shop our gianni versace metal mesh selection from top sellers and makers around the world. Global shipping available.

application of cnc machines in mould manufacturing|cnc machine for mold making