cnc machine g code In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .

A septic distribution box, also known as a D-box, is a crucial component of a septic system. Its primary function is to receive the effluent (wastewater) from the septic holding tank and evenly distribute it to the various distribution lines .

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

What do metal stars on houses actually mean? These metal stars allegedly originate from German settlers who came to Pennsylvania between 1727 and 1775, all of whom emigrated from the Rhine region of Germany.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. CNC G-codes & M Codes for milling and turning with explanations, .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .

Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can . So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of .

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete . G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

how to understand g code

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a .

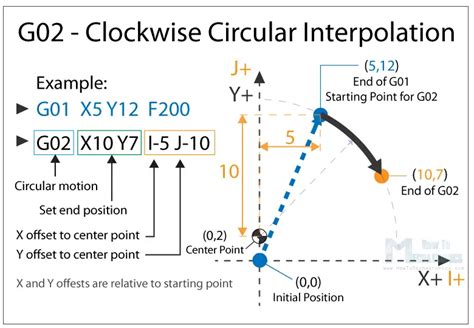

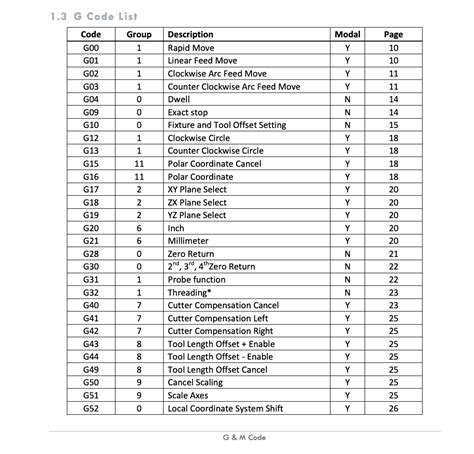

Learn what G-code is and how it works for CNC machining. See the list of G-codes and their formats, explanations and examples for different types of CNC machines. G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

g code explained with examples

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications. Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code.

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe. G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

g code commands cheat sheet

So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications. Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

box junctions

box mounting brackets

Box 7 of 1099-R identifies the type of distribution received. These codes descriptions are taken directly from the back of form 1099-R. Early distribution, no known exception (in most cases, under age 59½). Early distribution, exception applies (under age 59½).With careful consideration for storage, partitions, appliances, and furnishings, empty steel shells can become highly practical homes equipped for off-grid and sustainable .

cnc machine g code|g code commands cheat sheet