metal sheet stamping Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in . Yes, that's the correct box. It's a 4" octagon but measure it and you'll see it's less than 4". That is a 4" octagonal not a square. That is what any electrician would install for a wall or ceiling fixture unless something else else is specified. My electrical answers are based on 2017 NEC, you may have local amendments.

0 · wholesale custom sheet metal stamping

1 · sheet metal stamping near me

2 · sheet metal stamping design guidelines

3 · sheet metal stamping basics

4 · sheet metal stamping at home

5 · metal stamping service near me

6 · metal stamping process flow chart

7 · automotive sheet metal stamping process

Crossover boxes are often made of durable materials such as aluminum or steel to withstand the rigors of transportation and frequent exposure to the elements. They typically feature a hinged lid that opens upward, providing easy access to the contents inside. Most also come with locks or other security features to prevent unauthorized access.

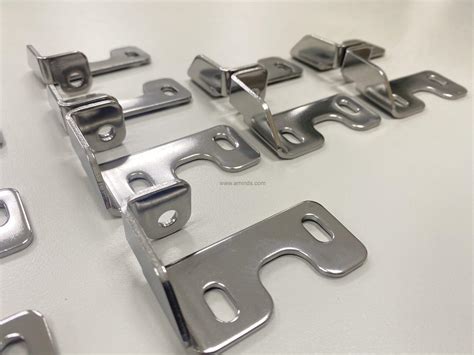

wholesale custom sheet metal stamping

Learn how metal stamping transforms flat metal sheets or coils into complex parts with various shapes and features. Explore the different types of stamping processes, presses, and dies, and their applications in various industries.Explore our in-depth guide on metal stamping, covering key processes, materials, precision techniques, and comparisons with CNC machining. Learn about surface finishes, die types, and how to select the best supplier for custom metal .

stainless steel 303 box sections

Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in . The sheet metal stamping process typically involves several key steps, each contributing to creating a high-quality metal component. Design and Die Creation. The sheet metal stamping process begins with designing the .Metal stamping is a cold-forming process that utilizes dies and stamping presses to transform sheet metal into specific shapes. It’s a complex process that can include several metal forming techniques, such as punching, blanking, embossing, bending, flanging, and coining, to produce precise parts for various industries.

Metal stamping is a manufacturing process used to convert flat metal sheets into various shapes using a number of metal forming techniques and designs. 800-486-5546. 800-486-5546. About. . The following guide illustrates best .Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force.

Metal stamping is a popular manufacturing process for developing parts with tight tolerances using sheet metal, like steel, copper, stainless steel, and aluminum. You can take advantage of metal stamping to manufacture products across diverse industries such as:Metal stamping is usually done by putting the metal sheet into a machine called a stamping press or power press. Following are the advantages of metal stamping: Because most of the stamping process is automated, you can produce your designs without much manual labor.Single punch stamping is a fast and efficient method of producing parts from sheet metal. Depending on the size and shape of your parts, the design template can be "nested" on the sheet metal prior to stamping for optimum part yield and minimal material waste. Ultimately, less scrap equals a lower cost per piece.

Sheet metal stamping is one of the most important manufacturing processes, where sheet metals are transformed into diverse shapes and parts. The process is placed within a stamping press wherein sheet metals take up or more sheet metal stamping dies, creating products adapted to usage in various industrial applications, including automotive, aerospace, .Synergy has specialized in prototype, short run sheet metal and emergency production stamping since 2011. We handle just about every type of stamping from deep draw to complex, high precision brackets. . Constructing prototype metal stamping parts for customers. We go a step further and work with your company to help develop and engineer your .Introduction to the sheet metal/ metal stamping industry BWC identified sheet metal and metal stamping employers among the top 10 workers’ compen-sation classifications with the highest fre-quency of claims and highest claims costs in Ohio. According to the National Council on Compensa-tion Insurance’s (NCCI’s) manual classifications,What Is Sheet Metal Stamping? Sheet Metal Stamping Process. There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping. Forming .

Metal stamping forms sheets of metal to create specifically shaped parts. Metal stamping also works with both ferrous and non-ferrous metals. However, stamping may have fewer options in terms of complexity and thickness. Each method brings unique advantages depending on the product design.MYD Metal specializes in the customization of various sheet metal stamping parts and precision springs. For many years, we have provided services to many customers in North America, Europe, Oceania and the Middle East. Our quality and fast delivery are praised by many of our customers which saved them considerable manufacturing costs.Sheet Metal Stamping Mechatrosys provides custom precision sheet metal stampings from coiled or blanked sheet metal. We can produce sheet metal parts in short runs or high volumes using processes like bending, cutting, and welding. Production processes include blanking, bending, embossing, punching, drawing, forming, piercing, laser cutting, welding, secondary machining, .Our metal sheet stamping department includes more than 20 mechanical presses (from 16 up to 630 tons) equipped with automated lines to use progressive dies. We also have hydraulic and mechanical presses for the simple single stroke .

Since 2005, TenRal has specialized in precision metal stamping services, gradually building a good reputation in the international market. We are committed to providing high quality, full types of sheet metal stamping components to customers in various industries, including but not limited to automotive, electronic, electrical and mechanical manufacturing. Learn Up: Precision Sheet Metal Stamping Sheet metal stamping is among the most common and necessary of all metalworking technologies. There’d be no body panels or bumpers on your car or truck without stamping. . Have you ever wondered what makes one metal sheet more suitable for stamping than another? Understanding the properties and specifications of various stamping materials is crucial for anyone in the metalworking industry. In this article, we will explore different types of materials like stainless steel, cold-rolled sheets, aluminum, and copper .

Metal stamping is a complex process that can include a number of metal forming processes — blanking, punching, bending, and piercing, to name a few. . Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible. When such factors .Sheet metal pressing, also known as fabrication metal sheet stamping or sheet steel pressing, is a metalworking process that involves using a press machine to transform a flat sheet of metal into a specific shape or form. The process typically involves placing the sheet metal between two dies, which are then pressed together using a high force .MYD Metal has specialized in the customization of various sheet metal precision stamping parts and CNC machining for more than 15 years. Email Us. get a Quote. Video profile. 360 Panoramic. VR. Who We are Professional CNC Sheet Metal Stamping fabricator. View Full Metal Stamping Parts Gallery >> Talan Products is a metal stamping manufacturer with equipment and expertise optimized for high-volume progressive die metal stamping production meeting ISO 9001:2015 quality .

Specializing in hard-to-produce, tight tolerance, appearance focused custom metal stampings, sheet metal fabrications, and assemblies. Short Run. Metal Sta mping. 2,000 - 50,000 pieces. Stage Tooling. Shorter Lead Times. Lower Cost Tooling & Parts. In-House Tool and Die Making. View More. High Volume Progressive.We are a leading manufacturer of Metal Stamping and Sheet Metal Fabrication, offering various engineered products. Through the use of the latest industry technologies such as Trumpf laser cutter, automatic press brakes, Amada CNC punch press, and robotics, together with our dedication to quality, MH Metal is to create added value for customers .Material saving: Metal Stamping minimizes material waste since it utilizes flat sheets or strips, optimizing material usage and reducing scrap. Applications of Metal Stamping Automotive industry: Metal Stamping is extensively used in the automotive sector for manufacturing components such as body panels, brackets, brackets, and structural parts.The metal sheets, usually made of aluminum, steel, or brass, are then placed between the die and the stamping machine. The machine applies pressure to the metal sheet, forcing it to conform to the shape of the die and create the desired component.

Precision for Your Sheet Metal Stamping Equipment . Whether you’re punching, blanking, bending, coining, embossing, flanging, cutting or sheering, sheet metal stamping is a precision business. Failure to stamp out a product correctly the first time can mean costly project overruns and lost time. FARO eliminates this measurement bottleneck .

sheet metal stamping near me

sheet metal stamping design guidelines

stainless steel bar cabinets

sheet metal stamping basics

Lighting, Light Fixtures, Ceiling and Exhaust Fans - 3 sets of wires coming into light/junction box, confused - Hey guys, So I have this junction box on the ceiling in my basement which runs a single light in the center of the room, the wiring is confusing to me though. each wire of course has black, white, and ground.

metal sheet stamping|sheet metal stamping basics