basic cnc machine maintenance checklist The right CNC machine maintenance not only results in high-end performance, it also means peace of mind. Operators and supervisors know that these valuable pieces of equipment are well cared for, and instant alerts will be sent if a . 36 in. Workpro Lateral File Cabinets at Office Depot & OfficeMax. Shop today online, in store or buy online and pick up in stores.

0 · preventative maintenance for cnc machines

1 · milling machine preventive maintenance checklist

2 · haas preventive maintenance checklist pdf

3 · cnc preventive maintenance checklist pdf

4 · cnc maintenance checklist pdf

5 · cnc machine maintenance manual pdf

6 · cnc machine maintenance checklist pdf

7 · cnc machine daily check sheet

We’re committed to providing each of our customers with high-performance CNC parts and quick service. Our technicians take great pride in returning our customers’ machinery to its full working capacity as quickly as possible.

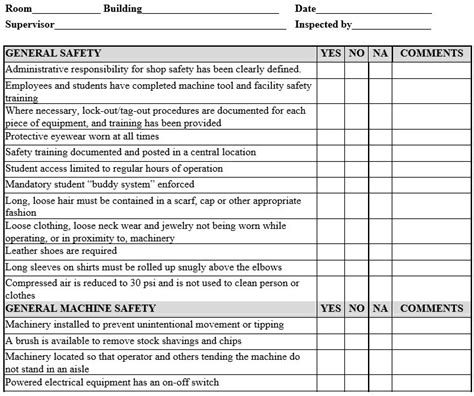

We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables and hoses, and checking coolant levels. CNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. 1-Ensure that the machine is clean near Chuck or spindle and Bed . 2 .Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean .The right CNC machine maintenance not only results in high-end performance, it also means peace of mind. Operators and supervisors know that these valuable pieces of equipment are well cared for, and instant alerts will be sent if a .

By following these steps, you can prevent breakdowns, avoid costly repairs, and prolong the lifespan of your CNC milling machine. Let's dive in! 1. Clean the machine thoroughly. 2. Check .In this blog post, we will provide you with a detailed preventive maintenance checklist specifically designed for CNC machines. And to facilitate your maintenance journey, we offer an Excel .

You should start maintaining with the 5 basic CNC machine maintenance tips, insights, and checklists to keep your machine tool running well with high speed, high machining quality, high precision, and long service life, .We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables and hoses, and checking coolant levels.

CNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. 1-Ensure that the machine is clean near Chuck or spindle and Bed . 2-Check all cover or Guard for security. 3- Clean the slide rails like door or Cover. 1-Check indicator lights for all components. 2-Test all the emergency push button.Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.

The right CNC machine maintenance not only results in high-end performance, it also means peace of mind. Operators and supervisors know that these valuable pieces of equipment are well cared for, and instant alerts will be sent if a problem occurs.By following these steps, you can prevent breakdowns, avoid costly repairs, and prolong the lifespan of your CNC milling machine. Let's dive in! 1. Clean the machine thoroughly. 2. Check for coolant leaks. 3. Inspect and clean the spindle. II. Weekly Maintenance: 1. Check and adjust machine alignment. 2. Inspect the tooling system. 3.In this blog post, we will provide you with a detailed preventive maintenance checklist specifically designed for CNC machines. And to facilitate your maintenance journey, we offer an Excel guide that simplifies the tracking and scheduling of maintenance tasks.

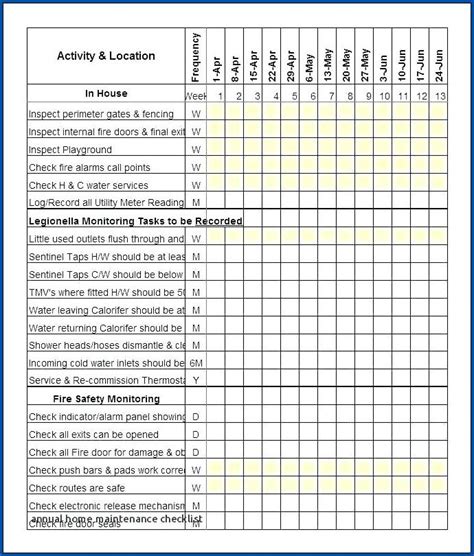

You should start maintaining with the 5 basic CNC machine maintenance tips, insights, and checklists to keep your machine tool running well with high speed, high machining quality, high precision, and long service life, and get benefits from making a regular maintenance schedule for your CNC machine tool. Basic CNC Checklist Maintenance tasks for CNC machines fall into three general categories: daily inspections, jobs that need to be performed every 500 hours or every six months, and additional inspections to be done every 1000 hours or every year.

HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine level

We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables and hoses, and checking coolant levels. CNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. 1-Ensure that the machine is clean near Chuck or spindle and Bed . 2-Check all cover or Guard for security. 3- Clean the slide rails like door or Cover. 1-Check indicator lights for all components. 2-Test all the emergency push button.Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.

preventative maintenance for cnc machines

Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.

The right CNC machine maintenance not only results in high-end performance, it also means peace of mind. Operators and supervisors know that these valuable pieces of equipment are well cared for, and instant alerts will be sent if a problem occurs.By following these steps, you can prevent breakdowns, avoid costly repairs, and prolong the lifespan of your CNC milling machine. Let's dive in! 1. Clean the machine thoroughly. 2. Check for coolant leaks. 3. Inspect and clean the spindle. II. Weekly Maintenance: 1. Check and adjust machine alignment. 2. Inspect the tooling system. 3.In this blog post, we will provide you with a detailed preventive maintenance checklist specifically designed for CNC machines. And to facilitate your maintenance journey, we offer an Excel guide that simplifies the tracking and scheduling of maintenance tasks.

You should start maintaining with the 5 basic CNC machine maintenance tips, insights, and checklists to keep your machine tool running well with high speed, high machining quality, high precision, and long service life, and get benefits from making a regular maintenance schedule for your CNC machine tool.

Basic CNC Checklist Maintenance tasks for CNC machines fall into three general categories: daily inspections, jobs that need to be performed every 500 hours or every six months, and additional inspections to be done every 1000 hours or every year.

milling machine preventive maintenance checklist

Maintain an organized filing system with this commercial file cabinet. The two spacious drawers accept letter and legal hanging file folders, and the precision ball-bearing suspension allows for smooth, quiet opening and closing.

basic cnc machine maintenance checklist|cnc machine daily check sheet