cnc machine chiller With units which can adjust coolant temperatures to track ambient temperature, machine base temperature, another reference or a fixed set point, there is a Thermal Care chiller for your application. Even complex part machining . $28.80

0 · water chiller system for home

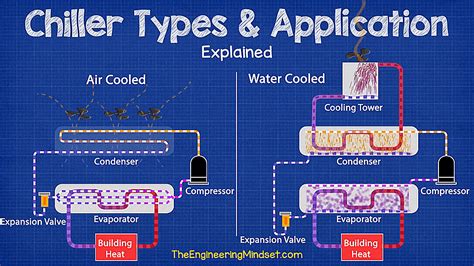

1 · types of water cooled chillers

2 · types of air cooled chillers

3 · industrial chilled water cooling system

4 · different types of chiller systems

5 · chiller types and operation

6 · chiller type air conditioning system

7 · chiller for air conditioning system

Book services and compare quotes from highly rated pros near you. How long does it take to replace an outside electrical meter box? When should I replace my outside electrical meter.

MP Systems Coolant Chillers are built specifically for the harsh environments of the CNC machining industry. They're intended for use with any machining .Built for harsh environments, CS Series Stand Alone Coolant Chillers are designed for machining applications where elevated coolant and machine tank .Industrial chillers optimize the performance of CNC machines across various dimensions, offering benefits that extend far beyond mere temperature control. Here’s how chillers contribute to the enhancement of CNC machine operations.

IBAG spindle chillers are the perfect solution to keep your CNC machine running smoothly. Our machine tool chillers are engineered to provide reliable and efficient cooling for a wide range of spindle types and sizes, ensuring optimal .With units which can adjust coolant temperatures to track ambient temperature, machine base temperature, another reference or a fixed set point, there is a Thermal Care chiller for your application. Even complex part machining .Better Cooling for Your Fadal CNC Machines. The Oasis Chiller Unit with Power Cord & Fittings (21 Amp) is a smart solution to cool your CNC machines. This Fadal CNC Chiller Unit Online keeps your equipment from getting too hot, .TEYU S&A CNC Machine Tool Chillers are extremely helpful in dissipating the heat from the spindles of CNC machine tools. They offer cooling precision from ±1℃ to ±0.3℃ and .

An industrial water chiller, specifically designed for cooling CNC machines, uses circulating cooling technology to promptly remove the heat generated by the high-speed rotation of the spindle, ensuring that the spindle .

water chiller system for home

Coolant chillers are essential to your machining operation. Metalworking fluids must be maintained at a constant and correct temperature for your application to ensure you produce consistent high-quality parts.The Haas Coolant Chiller reduces the temperature of the machine’s coolant, before it is circulated through the machine. The system is effective whenever the flood coolant pump is on. Warm coolant from the tank (red hoses in the illustration) is pumped through a filter and into the Chiller.MP Systems Coolant Chillers are built specifically for the harsh environments of the CNC machining industry. They're intended for use with any machining application where an increase in coolant or machine tank temperature could cause problems holding tight tolerances.Built for harsh environments, CS Series Stand Alone Coolant Chillers are designed for machining applications where elevated coolant and machine tank temperatures may cause problems holding tight part tolerances.

Industrial chillers optimize the performance of CNC machines across various dimensions, offering benefits that extend far beyond mere temperature control. Here’s how chillers contribute to the enhancement of CNC machine operations.

types of water cooled chillers

IBAG spindle chillers are the perfect solution to keep your CNC machine running smoothly. Our machine tool chillers are engineered to provide reliable and efficient cooling for a wide range of spindle types and sizes, ensuring optimal performance and long tool life.With units which can adjust coolant temperatures to track ambient temperature, machine base temperature, another reference or a fixed set point, there is a Thermal Care chiller for your application. Even complex part machining requiring high pressure chip removal systems are no .

Better Cooling for Your Fadal CNC Machines. The Oasis Chiller Unit with Power Cord & Fittings (21 Amp) is a smart solution to cool your CNC machines. This Fadal CNC Chiller Unit Online keeps your equipment from getting too hot, making sure they work well. Checkout the CNT-0278-KIT and what it can do for your Fadal CNC Machine. How It Works

TEYU S&A CNC Machine Tool Chillers are extremely helpful in dissipating the heat from the spindles of CNC machine tools. They offer cooling precision from ±1℃ to ±0.3℃ and refrigeration power from 600W to 42000W. An industrial water chiller, specifically designed for cooling CNC machines, uses circulating cooling technology to promptly remove the heat generated by the high-speed rotation of the spindle, ensuring that the spindle operates within an appropriate temperature range.

Coolant chillers are essential to your machining operation. Metalworking fluids must be maintained at a constant and correct temperature for your application to ensure you produce consistent high-quality parts.The Haas Coolant Chiller reduces the temperature of the machine’s coolant, before it is circulated through the machine. The system is effective whenever the flood coolant pump is on. Warm coolant from the tank (red hoses in the illustration) is pumped through a filter and into the Chiller.MP Systems Coolant Chillers are built specifically for the harsh environments of the CNC machining industry. They're intended for use with any machining application where an increase in coolant or machine tank temperature could cause problems holding tight tolerances.

electric blues box slide guitar kit review

Built for harsh environments, CS Series Stand Alone Coolant Chillers are designed for machining applications where elevated coolant and machine tank temperatures may cause problems holding tight part tolerances.Industrial chillers optimize the performance of CNC machines across various dimensions, offering benefits that extend far beyond mere temperature control. Here’s how chillers contribute to the enhancement of CNC machine operations.

IBAG spindle chillers are the perfect solution to keep your CNC machine running smoothly. Our machine tool chillers are engineered to provide reliable and efficient cooling for a wide range of spindle types and sizes, ensuring optimal performance and long tool life.With units which can adjust coolant temperatures to track ambient temperature, machine base temperature, another reference or a fixed set point, there is a Thermal Care chiller for your application. Even complex part machining requiring high pressure chip removal systems are no .Better Cooling for Your Fadal CNC Machines. The Oasis Chiller Unit with Power Cord & Fittings (21 Amp) is a smart solution to cool your CNC machines. This Fadal CNC Chiller Unit Online keeps your equipment from getting too hot, making sure they work well. Checkout the CNT-0278-KIT and what it can do for your Fadal CNC Machine. How It Works

TEYU S&A CNC Machine Tool Chillers are extremely helpful in dissipating the heat from the spindles of CNC machine tools. They offer cooling precision from ±1℃ to ±0.3℃ and refrigeration power from 600W to 42000W. An industrial water chiller, specifically designed for cooling CNC machines, uses circulating cooling technology to promptly remove the heat generated by the high-speed rotation of the spindle, ensuring that the spindle operates within an appropriate temperature range.

electric box 2 level 8

types of air cooled chillers

Plastic boxes are the most common choice for residential wiring projects. They are lightweight, easy to install, and less expensive than metal options. Plastic boxes are also non-conductive, reducing the risk of electrical shock, and they’re compatible with .

cnc machine chiller|different types of chiller systems