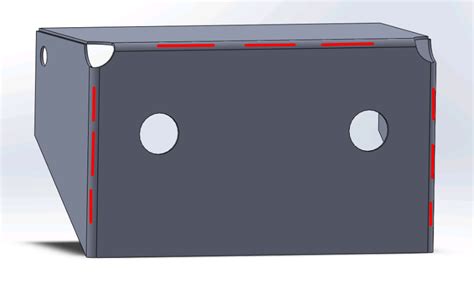

sheet metal relief cuts Relief Cuts. Relief cuts help parts fall closer to design intent to avoid “overhangs” and tearing at bends. Overhangs become more prominent for thicker parts with a smaller bend radius, and may even be as large as ½ the material’s thickness. . Here’s a more streamlined version of the comparison table for the CNC machines: 1. SainSmart Genmitsu 3018-PROVer CNC Router Machine. Check It Out Here! The SainSmart Genmitsu 3018-PROVer represents an affordable entry-level option in the CNC router market, tailored for engraving and light cutting.

0 · solidworks sheet metal relief cut

1 · solidworks sheet metal corner relief

2 · sheet metal pattern layout methods

3 · sheet metal fabrication design guide

4 · sheet metal corner relief chart

5 · sheet metal bending chart

6 · bend relief sheet metal solidworks

7 · auto relief solidworks sheet metal

15 votes, 12 comments. 212K subscribers in the Whatisthis community. Welcome to r/whatisthis, a subreddit for identifying objects of unknown make.

Learn how to design sheet metal parts with bend relief, small holes, and minimum flange widths to avoid tearing, cracking, and distortion. .

A bend relief is nothing more than two small incisions cut into a piece of sheet metal to free the metal between the two. It separates the . Relief cuts refer to notches or cuts made in the sheet metal to facilitate bending, minimize stress, and prevent material deformation or tearing. These cuts usually occur in areas with complex shapes or tight bends, where .

Relief Cuts. Relief cuts help parts fall closer to design intent to avoid “overhangs” and tearing at bends. Overhangs become more prominent for thicker parts with a smaller bend radius, and may even be as large as ½ the material’s thickness. .

Corner Fillets and Relief Cuts. Sheet-metal parts may have sharp corners, but designing a fillet of ½ the material’s thickness will make parts more cost-effective. In sheet metal design, bend relief refers to a small cut or notch made at the intersection of two bend lines. Its purpose is to prevent material deformation, tearing, and other issues during the bending process. . Bending . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab .

Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . bend relief cut into the part, again the depth of the relief should be greater than the radius of the bend. The width of the relief should be a material thickness or greater, preferably a material This doesn’t just work with thin sheet metal. You can use this method to bend material that would make a sheet metal bending brake cry. So what is this 2-step diy bending process that can do the job of a press brake? Here’s the secret: Step 1 – Make relief cuts in your part along the line you want to bend. Step 2 – Bend. That’s it, no . Sheet Metal Bending: What to Avoid for Better Results Video Guide. Key Concepts of DFM for Bending. In bending, DFM is the process of designing parts to accommodate manufacturing constraints. Because bending is inherently complex, it requires precise tooling, alignment, and clearance. . Bend relief, or slight cuts at bending points, helps .

We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts.Select the Sketch Bend tool in the Sheet Metal Tools section of the Sheet Metal tab. The Sketch Bend dialog box is shown.; In the Alignment options select either the Inside, Outside, Adjacent or Center option.; Select a planar face on the sheet metal that the sketch bend will be created on and set a Bend Angle.; The view will change to a sketch mode view and the Line tool will be .• For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but require high-cost tooling. [email protected] | 607.227.7070 | www.incodema.com Cut relief between external features. Internal bend relief mustRelief Ratio. The distance d represents the width of the Rectangular or Obround relief cut and the depth by which the side of the Rectangular or Obround relief cut extends past the bend region. The distance d is determined by the following equation:. d = (relief ratio) * (part thickness)

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model . What Is Bend Relief? In sheet metal, a bend relief is an incision cut along the sides of a planned bend. Though bend relief lengths and widths vary between projects, they all share a common goal: preventing tearing and part deformation during the bending process. During the bending of sheet metal, material around the bend tends to stretch and .

solidworks sheet metal relief cut

Use this sheet metal bending design guidelines when designing your parts for manufacturing. 1. Bend Relief 2. Curling 3. . To ensure successful bending, the width of the relief cuts should be at least equal to the material thickness, and the length should be longer than the radius of the bend. 2. Bends where the flanges aren’t adjoining. SOLIDWORKS 2018 What’s New – SOLIDWORKS Sheet Metal Three Bend Corner Relief – #SW2018. SOLIDWORKS Sheet Metal 2018 includes two enhancements to Three Corner Bend Relief, adding solutions for the corner flange challenges Sheet Metal designers run into.. Corner Relief Display. SOLIDWORKS 2018 enhancement to the 3 Corner Relief can now .Tangent —Creates the relief cuts tangent to the middle bend edges. Closed —Creates a corner patch that is flattened during an unbend operation. 4. Set the offset value and width of the gap. Flat Walls. To follow this procedure you must have created multiple flat walls, or a flat wall with a pair of tangent wall segments. 1. Basically, he makes the extruded flange in sheet metal then cuts a slot with extrusion in the flat pattern. Fusion 360 misses small holes and bend slots Fusion 360 - CAM. When it comes to bend relief cuts, this has been the .

11 gauge sheet metal brake

Change the bend relief cut location in Fusion 360 Sheet Metal. It is not possible to choose the location of the bend relief as that is determined by the sheet metal rules. However the position of the relief cut can be adjusted by editing the sheet metal rules and possibly by changing the edge selection and direction of the flange bend Bend relief is a term used in sheet metal design to describe a small cut or notch made at the intersection of two bend lines. This helps prevent material deformation, tearing, and other issues during the bending process.This crucial element allows the sheet metal to bend more easily, creating a smoother transition between bends and flat surfaces.

Sheet Metal Relief cut for bends. RM By Rick McDonald 02/26/13. In my company we do not have press breaks so we do all our sheet metal bending by hand or farm out larger parts. Most of what we make is done with 6061 aluminum. We also need need to make tight bends due to the products we build.

11 10 electrical box

solidworks sheet metal corner relief

Assuming the parts will be laser cut, you can just leave the corners like that. It shouldn't be a problem. You can edit the flat pattern feature properties and try toggling the corner treatment setting. You can also add corner trims to the flat by hitting the flatten button then going to Insert > sheet metal > corner trim.Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: Do one of the following: Click . Cuts the corner relief with the gap. Fill in some gap . Extends the corner relief material into the gap. Parent topicCorner Reliefs and . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Quick video showing how to program relief cuts or straight line cuts in fusion 360 for plasma CNC table users. I use this in order to add relief cuts to my p.

Small holes in sheet metal can be punched or can be laser cut, depending on the equipment used for punching. As general guideline suggests , hole diameter equal to sheet thickness can be punched. . Bend Relief. When sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to tear depending on the geometry of .Relief sheet metal part design. See below an example of a flange that has been offset to avoid the need for a relief cut. Offset added sheet metal part design rules. It is important to consider whether the flange corners are to be closed or not, they may require a gap to allow for welding. Weld gap sheet metal part design rules Sweet Relief – How to avoid hole distortion in sheet metal parts Sheet metal fabrication is an excellent method of making mechanical parts, especially support brackets. They tend to be cheap, light, strong, and easy to pack and ship. In this article, I explain how to avoid hole distortion in sheet metal parts. Ideally, when sheet metal is .

sheet metal pattern layout methods

Yellow box junctions keep the junction clear for through-traffic to avoid traffic jams. They also keep a road space free to ensure fire engines always have a clear exit from fire stations..

sheet metal relief cuts|solidworks sheet metal corner relief