making vent sheet metal chassis cheaper Sheet metal is one of the most commonly used materials in manufacturing. The properties of sheet metal, such as its malleability, hardness and durability make it ideal for many . An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

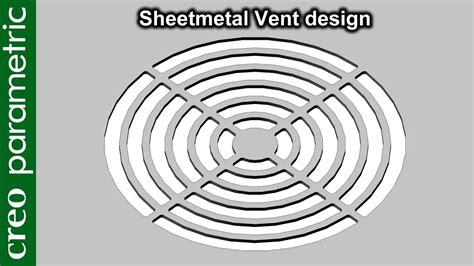

0 · sheet metal vent designs

1 · sheet metal enclosure ventilation systems

2 · sheet metal enclosure ventilation reviews

3 · sheet metal enclosure ventilation requirements

4 · sheet metal enclosure vent design

5 · forced sheet metal vents

6 · forced sheet metal ventilation

7 · forced sheet metal enclosure ventilation

Box sets are aimed at an aging demographic that still prefers physical media. That aging demographic also tends to have more money than younger music fans. So they roll out these "ultimate," "super deluxe," and "uber" box sets to maximize the profit.

Vent patterns, in particular, can get costly when the patterns have a large number of small cutouts. Switching to longer slots for your vent cutouts, or using perforated sheet metal, .This resource will cover the key elements of designing custom enclosures that .1. Reduce the Number of Parts. Combining two or more parts into a single one is a cost-effective way to reduce the price of sheet metal fabrication jobs. If you can attach two parts via a bend, or turn separate panels into a single piece, it is .Sheet metal is one of the most commonly used materials in manufacturing. The properties of sheet metal, such as its malleability, hardness and durability make it ideal for many .

Access Points: Design doors, panels, or hatches for easy access to the interior components. Mounting Provisions: Include mounting holes, brackets, or flanges for securing .

Here are several strategies to make sheet metal parts more cost-effective: 1. Design for Manufacturability (DFM) Simplify Design: Minimize complex features and .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on . How to easily make a decorative custom air vent cover to replace your basic metal wall vents!

Our custom sheet metal chassis service are of the highest quality and most affordable prices. Finish the parts in time to provide the strongest support for your R&D projects. Do sheet metal manufacturing according to your drawings or . 1 was here. General Sheet Metal Work /Residential Venting / Commercial Ventilation / Ductwork / Exhaust SystemsSheet metal ducting in homes is actually uncommon now. Steel duct made to run between the spaces in walls is a relatively commonly used product, but most of the ductwork run under homes and in the attics is plastic over a coil of steel. It's insulated with about an inch of fiberglass wool, and covered with a plastic plastic/foil laminate sleave.

I was wondering if anyone had any tips for making sheetmetal chassis on Solidworks. This is the first time that I am experimenting in sheetmetal and want to get it right. . Chief Delphi Tips For Making a Sheet Metal Chassis on SolidWorks. Technical. CAD. O_Sancheski June 16, 2011, 4:49pm . to get it right. Thanks. Frenchie461 June 16, 2011 . This is straightforward if using Forced Ventilation (i.e. fans). Just make sure to use a fan, or multiple fans, that exceeds your requirement by a reasonable safety factor. You must then make sure that the air can flow in and out of the enclosure without constriction. Forced sheet metal ventilation is typically used for higher power . I would do a tube frame and save the sheet metal resource for superstructures, personally. Making a WCD nowadays takes very little time, and for us at least it makes more sense to go with that rather than use our sponsor’s time making the chassis for us. However, having flanged sheet metal for superstructures is very lightweight and nice IMO. It is an automotive sheet metal fabrication process that uses heat to join two or more materials. Common welding techniques include spot welding, MIG welding and TIG welding. Sheet metal welding is suitable for joining similar materials. It is highly compatible with many materials and can create strong and durable auto parts.

what kind of metal, what tolerances, what is cheap to you? getting small run sheet metal is pretty cheap. One off milled aluminum parts are less cheap. The price goes up as the complexity and tolerances go up as well as the hardness of the metal. . Nope, look for a local sheet metal place. A lot of the metal suppliers will do laser cutting to .Mid-high end MSI, Alienware, ASUS Zephyrus and some Acer like the Triton 500SE all have metal chassis. However, do note that some laptops have a hybrid plastic-metal chassis but just state that they have a metal chassis. For instance, the Helios 300, Legion 5 Pro among others have both plastic and metal components.

Hello all, first let me say I haven't done any casting so if this particular project is ultrahard, forgive me for not recognizing so and feel free to.

As an hvacer, I use sheet metal angle. Always some laying around and non combustible for commercial applications. . I like cheap solutions.. Keep the vent, it's plastic and easy to drill two holes, one on either end. Screw the vent to the ceiling through the drywall and into a piece of wood you have glued to the back of the drywall. Reply reply

Our own prototype sheet metal shop had no particular difficulty doing the extruding, given a reasonable tolerance and a few test articles. Express tapping goes really quick, especially if you have an auto-reversing tapping head. Your usual suppliers should have no great difficulty doing it, and it should be much cheaper than clinch nuts. Mike .However, the vents all still remain on the floor, opening up to the ground below. Is there a cheap/nice looking way to seal off the bottom of the vent so I can keep the look without having to put in a vent? One of the companies I talked to quoted me 0/vent. Or alternatively, a nice looking vent cover?

metal mesh box with lid

Approved Sheet Metal (ASM) excels at fabricating custom sheet metal chassis. We understand that many industries rely on precise, high-precision fabricated parts. Our team of dedicated sheet metal mechanics, laser operators, and programmers get it, we understand that speed and price won’t make a difference if the parts aren’t right. If I were making this, I would provide for a safty ground system below the wood top plate just as there would be with a metal chassis. Perhaps a wide piece of sheet copper below the transformers. That is, one wide enough to span all three transformers with appropriate holes for both the wires and all the mounting bolts.

Like anything in product development, deciding to machine a laptop unibody chassis and cover from slab of aluminum is a set of trade-offs. There are no huge benefits over typical packaging methods of a stamped sheet metal chassis with injection molded covers, magnesium diecast or machined aluminum unibody; each has strengths and weaknesses. 1999 - 2003 7.3L Power Stroke Diesel - AV8or1's epic sheet metal weld in update for new style cab vents. egged on by Y2K's leaking vents. . 1968-Present E-Series Van/Cutaway/Chassis; Ranchero & 1961 - 1967 Econoline . with a dirt cheap example vent to work with. You've already done the hard work of moving your bed back and clearing out . SolidWorks TutorialsAdvanced ModelingSheet Metal PartVent Sheet metal cutting is a fundamental step in manufacturing, where flat metal sheets are cut into specific shapes and sizes. The cutting method depends on factors like material type, thickness, and the complexity of the design.Here are the .

in this tutorial video i will show you sheet metal vent tool tutorial .& i hope you will enjoy the tutorial, please subscribe our channel for more videos &.Aluminum or metal chassis tend to also trap heat more. Plastic will stay cool to the touch while metal can get extremely hot. Honestly, gaming metal laptops can get uncomfortable hot with areas that need to cool before you can even touch them. Metal is nice and premium, but you also get a hotter laptop that will exhaust hotter air. 1. Design Optimization. Simplify Designs: Reduce complex features that require additional cutting, forming, or welding. Fewer bends, holes, and complex shapes will reduce fabrication time and costs. Standardize Components: Use standard sizes and shapes for parts wherever possible, reducing the need for custom tools or processes. Optimize Material Usage: .

New Perrin crank pulley. New carbon trim around infotainment,vents, switches. Added pics of turbo inlet hose and mechanical bypass valve. Hand painted top of oil cooler.Spot approves! The oil cooler would normally mount up high but i have Hella horns so i mounted it low. Two bolts thru lower radiator support sheet metal and added 90 deg fittings.

sheet metal vent designs

How many square inches of sheet metal are used to make the vent transition shown? (The ends are open.) 8" 8" 1 13" 7" 7"Best choice you have is looking for Zinc sheet/foil distributors or wholesalers buying it from retail sales or resalers is why you’re finding such high pricing. The website I linked is pretty reliable but you’ll still have to dig to find what you’re looking for. It depends most what gauge and size you’re looking for, and whether it’s readily available. These dies are CNC machined steel and can handle steel or aluminum sheet metal up to 16 gauge (.060” thick). To use these, start by cutting a hole in the sheet metal to the size of the dimple die you are using, then hold the dimple over your hole and tighten the bolt.

metal mixing cheat sheet

If your vent is larger, these metal sheets come in various sizes that should work! The inside of our vent is black, so you can't see the metal inside the wall. If your vent is lower on the wall, consider that you may be able to see inside if you change to this sheeting.

metal mug storage box

metal military medical drop box

metal mesh grill sheet

What is a Junction Box? Vorlane defines junction boxes as enclosures for protecting and safeguarding electrical connections. They are also suitable for organizing big loops of wires in a place. A junction box also combines different cables when needed.

making vent sheet metal chassis cheaper|forced sheet metal vents