sheet metal bending solidworks Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .

An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. [1] Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

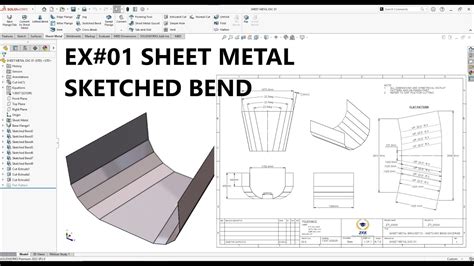

0 · solidworks sheet metal sketched bend

1 · solidworks sheet metal simulation

2 · solidworks sheet metal round bend

3 · solidworks sheet metal relief cut

4 · solidworks sheet metal k factor

5 · solidworks sheet metal bend lines

6 · sketched bend in solidworks

7 · sheet metal exercises solidworks pdf

Sheet metal screws work by digging into sheet metal with their fully threaded shank. It’s difficult — or impossible in some cases — to drive a conventional screw into sheet metal. As previously mentioned, only part of their shank is covered with external threading.

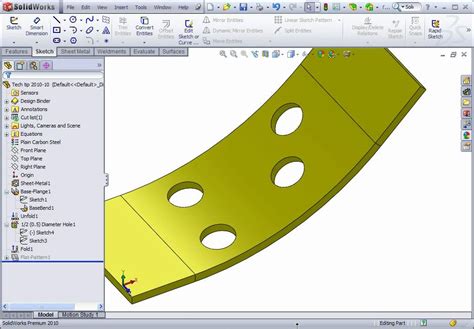

When bending sheet metal, you can create round bends instead of sharp bends. The Insert Bends feature also allows you to create rips. To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part.

amazon software development engineer online assessment junction box question

This Solidworks tutorial is show you how to bend a part with sketched bend in sheet metal features, check it out!!!.more. Initiating a base feature like the Extruded Boss/Base - we will show you how to set up a Sheet Metal part using the Base Flange/Tab feature instead which will concurrently set up your basic.You can add bend lines to a flat face of a sheet metal part with a sketched bend feature. This lets you dimension the bend line to other geometry.

solidworks sheet metal sketched bend

Here we will learn how to use Sketched bend command in Solidworks sheet metal and create a bend at any part of plan surface, at any angle and dimension.1)Sol.Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .

Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. . Tables are included in the SOLIDWORKS application, and are located in: \lang\\Sheet Metal Gauge Tables\.SheetMetalWorks is an add-in for companies that use SOLIDWORKS to design sheet metal for bending. SheetMetalWorks speeds up the design process and delivers automated calculations, flawless unfolding of complex parts, easy . SolidWorks – How to create a simple Sheet Metal part in SolidWorks. A quick tour and introduction using the SolidWorks Sheet Metal Sketch Bend Feature. In .2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the

solidworks sheet metal simulation

solidworks sheet metal round bend

SolidWorks Sheet Metal has a lot of useful and time saving features. One benefit is the ability to create a flat pattern of a complex sheet metal shape. This tutorial will cover setting up the sheet metal properties, as well as using “Edge Flange” and “Sketched Bend” features.

For example, a Sketched Bend sheet metal feature has a SketchBend as the individual bend that is absorbed in the Sketched Bend feature. To edit individual bends: In the FeatureManager design tree, expand a sheet metal feature. . Version: SOLIDWORKS 2020 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help .

Select the top face of the tab, then click Sketched Bend (Sheet Metal tab). Sketch a horizontal line of any length. Dimension it as shown. . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, . Hi, This video demonstrates how to create an animation of sheet metal bends folding using SOLIDWORKS motion study and macros in a matter of few clicks: Animate folding of SOLIDWORKS Sheet Metal bends - YouTube Thanks, Artem Catalog. View .Click Sketched Bend on the Sheet Metal toolbar, or click Insert > Sheet Metal > Sketched Bend.; In the graphics area, select a face that does not move as a result of the bend for Fixed Face.; Click a Bend position of Bend Centerline, Material Inside, Material Outside, or Bend Outside.; Set a value for Bend Angle, and click Reverse Direction if necessary. .Default: Sets the default Bend Method to use for all bends in the model.: Bend Method: Sets the name of the bend method. Setup Cost: Sets a setup cost per lot for the bend method. When the Bend Method is used during the Costing calculation, this Setup Cost is added to the Setup folder in the CostingManager and it is divided by the lot size to get the setup cost per part.

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .Here we will learn how to use Sketched bend command in Solidworks sheet metal and create a bend at any part of plan surface, at any angle and dimension.1)Sol.

Click Sketched Bend on the Sheet Metal toolbar, or click Insert > Sheet Metal > Sketched Bend.; In the graphics area, select a face that does not move as a result of the bend for Fixed Face.; Click a Bend position of Bend Centerline, Material Inside, Material Outside, or Bend Outside.; Set a value for Bend Angle, and click Reverse Direction if necessary. .Sheet metal bend line notes allow: Editing content; Modifying default format. Edit install_dir\lang\language\bendnoteformat.txt; Maintaining associative capabilities. Change the bend angle, bend direction, or bend radius, and the notes update in the drawing. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and .

You can calculate the developed length of sheet metal parts using bend calculation tables. Editing the Default Bend Radius, Bend Allowance, Bend Deduction, or Relief Type. A Sheet-Metal1 feature in the FeatureManager design tree indicates a sheet metal part. The Sheet-Metal1 feature contains the default bend parameters. Of all concepts in sheet metal design, bending and flattening are two of the most fundamental and important to understand. In this blog article, we will look at the basic theory behind sheet metal bends, particularly the Bend Allowance (BA), and how to apply this knowledge when utilizing SOLIDWORKS sheet metal tools.The main concept revolves around the idea of . Help Content Version: SOLIDWORKS Connected Tutorials (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.

To cut across a bend, you start by unfolding only the bend that you want to cut across. Unfolding only one bend results in faster system performance. Click Unfold (Sheet Metal tab). In the graphics area, select the face and bend as shown for Fixed face and Bends to unfold.

solidworks sheet metal relief cut

Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. . Tables are included in the SOLIDWORKS application, and are located in: \lang\\Sheet Metal Gauge Tables\.Now, fold the bend back to its bent state. Click Fold (Sheet Metal tab). In the PropertyManager, click Collect All Bends to add all unfolded bends to Bends to fold. Click . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions .For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of .You can calculate the developed length of sheet metal parts using bend calculation tables. Editing the Default Bend Radius, Bend Allowance, Bend Deduction, or Relief Type. A Sheet-Metal1 feature in the FeatureManager design tree indicates a sheet metal part. The Sheet-Metal1 feature contains the default bend parameters.

You can calculate the developed length of sheet metal parts using bend calculation tables. Editing the Default Bend Radius, Bend Allowance, Bend Deduction, or Relief Type. A Sheet-Metal1 feature in the FeatureManager design tree indicates a sheet metal part. The Sheet-Metal1 feature contains the default bend parameters.

Sheet Metal - Default Bend Parameters. A Sheet-Metal1 feature in the FeatureManager design tree indicates a sheet metal part. The Sheet-Metal1 feature contains the default bend parameters. To edit the default bend radius, bend allowance or bend deduction, or default relief type: Under Sheet Metal Gauges, select Use gauge table, and select a table .You can add bend lines to a flat face of a sheet metal part with a sketched bend feature. This lets you dimension the bend line to other geometry. Sketch on sheet metal face: Sketched bend applied: . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

solidworks sheet metal k factor

Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application. What is a Gang Box?

sheet metal bending solidworks|solidworks sheet metal k factor