change sheet metal thickness inventor To create a sheet metal rule, copy the supplied Default rule (or an existing rule) . Quite often low voltage stuff (TV, phone, etc.) uses back to back plaster rings. There may be a fire code issue. Depending on what the wall is separating, you may have restrictions on penetrations and a box going from one side to the other or even 2 boxes too close together on both sides of a wall. would be a penetration.

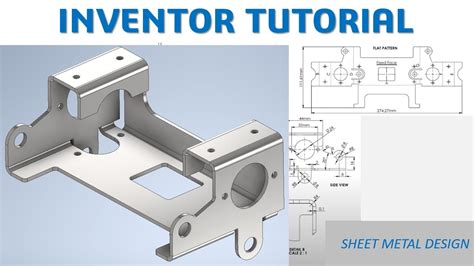

0 · sheet metal inventor tutorial pdf

1 · inventor unfold sheet metal

2 · inventor sheet metal rules

3 · inventor sheet metal exercises pdf

4 · inventor sheet metal defaults

5 · edit sheet metal rule inventor

6 · convert to sheet metal inventor

7 · autodesk inventor sheet metal tutorial

Molded from PVC it’s extremely durable and resistant to impacts in a wide range of temperatures and not adversely affected by water or chemicals. Built for corrosive environments, the Scepter junction box is entirely nonmetallic eliminating corrosion concerns with .

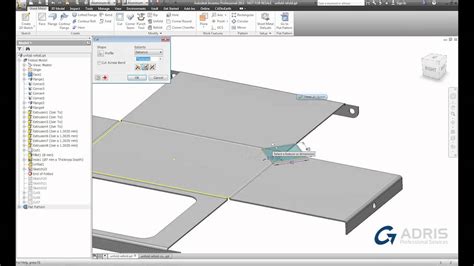

Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it.go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use .Use the Sheet Metal Defaults dialog box to change the options and parameters .To create a sheet metal rule, copy the supplied Default rule (or an existing rule) .

Inventor can create specific custom iProperties and classify by them. Use .Create a sheet metal part using the sheet metal template. The template uses your .If you modeled it in a sheet metal environment, you can simply change the . go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value.

This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucadUse the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body . Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.To create a sheet metal rule, copy the supplied Default rule (or an existing rule) and make and save changes to the selections and values on all three tabs. Click Manage tab Styles and .

sheet metal inventor tutorial pdf

Inventor can create specific custom iProperties and classify by them. Use the following steps: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal .

To edit the sheet metal rule, click the Edit Sheet Metal Rule button on the dialog. dialog, you can set the sheet preferences such as sheet thickness, material, flat pattern bend angle .Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a .

If you modeled it in a sheet metal environment, you can simply change the parameters - sheet metal rule to change the thickness; and edit operations related to individual segments and change the radius value in the . Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it. go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value.This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucad

inventor unfold sheet metal

Use the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body in a multibody part.

Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.To create a sheet metal rule, copy the supplied Default rule (or an existing rule) and make and save changes to the selections and values on all three tabs. Click Manage tab Styles and Standards panel Styles Editor to open the Style and Standard Editor dialog box.

cnc precision machining north west

Inventor can create specific custom iProperties and classify by them. Use the following steps: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal Parameters should be parameter: "Thickness". Export this parameter to custom iProperties by selecting the following check-box. Click Done.To edit the sheet metal rule, click the Edit Sheet Metal Rule button on the dialog. dialog, you can set the sheet preferences such as sheet thickness, material, flat pattern bend angle representation, flat pattern punch representation and gap size. 3. In the Sheet tab, set the Thickness to 0.12 and leave all the default settings. 4.

Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a profile for a base face or an initial contour flange. If you modeled it in a sheet metal environment, you can simply change the parameters - sheet metal rule to change the thickness; and edit operations related to individual segments and change the radius value in the dialog box. Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it.

go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value.This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucadUse the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body in a multibody part.

inventor sheet metal rules

Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.To create a sheet metal rule, copy the supplied Default rule (or an existing rule) and make and save changes to the selections and values on all three tabs. Click Manage tab Styles and Standards panel Styles Editor to open the Style and Standard Editor dialog box.

Inventor can create specific custom iProperties and classify by them. Use the following steps: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal Parameters should be parameter: "Thickness". Export this parameter to custom iProperties by selecting the following check-box. Click Done.To edit the sheet metal rule, click the Edit Sheet Metal Rule button on the dialog. dialog, you can set the sheet preferences such as sheet thickness, material, flat pattern bend angle representation, flat pattern punch representation and gap size. 3. In the Sheet tab, set the Thickness to 0.12 and leave all the default settings. 4.Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a profile for a base face or an initial contour flange.

inventor sheet metal exercises pdf

inventor sheet metal defaults

edit sheet metal rule inventor

NEMA 2 enclosures provide protection in indoor environments against the ingress of solid objects and light splashing or dripping water. Rugged NEMA 2 boxes are available from Polycase in ABS plastic, polycarbonate, steel, and stainless steel.

change sheet metal thickness inventor|edit sheet metal rule inventor