machine coordinate system cnc Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific . The code(s) in Box 7 of your Form 1099-R helps identify the type of distribution you received. We use these codes and your answers to some interview questions to determine if your distribution is taxable or subject to an early withdrawal penalty.

0 · what is g54 cnc code

1 · understanding cnc offsets

2 · right hand rule for machining

3 · cnc xyz axis chart

4 · cnc mill axis diagram

5 · cnc machine axis locations diagram

6 · cnc machine axis identification

7 · cnc cartesian coordinate system

Shop Kobalt 28-in W x 28-in H x 12.5-in D Wall-mounted Steel Garage Cabinet in Silver in the Garage Cabinets department at Lowe's.com. With heavy-duty construction and a powder-coated finish, this cabinet offers a durable storage solution for your garage.

what is g54 cnc code

In the manufacturing industry, with regard to numerically controlled machine tools, the phrase machine coordinate system refers to the physical limits of the motion of the machine in each of its axes, and to the numerical coordinate which is assigned (by the machine tool builder) to each of these limits. CNC Machinery refers to machines and devices that are controlled by using programmed commands which are encoded on to a storage medium, and NC refers to the auto. Learn coordinate system fundamentals for any CNC machine, from the cartesian coordinate system to tool offsets. Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific .

A comprehensive understanding of G-code fundamentals, tool movements, workpiece positioning, and tool offsets is essential for programming the CNC lathe coordinate system. Mastery of these aspects empowers machinists to .

On FANUC CNC machines, the Absolute, Relative, and Machine display screens provide different views of the machine's positional data. These screens are used by operators .

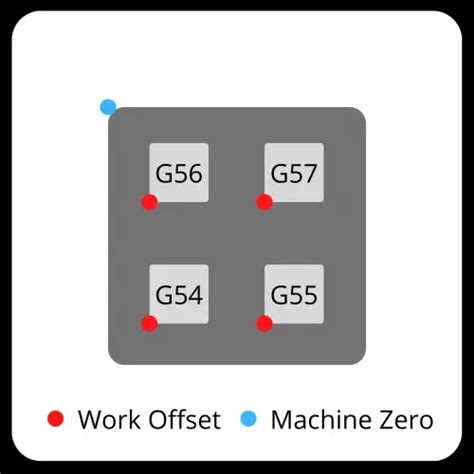

One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC .G54, G55, G56, G57, G58, and G59 (Usually referred to as “ G54-G59 “) are a group of CNC codes that specifies the “work offset” or the location of the workpiece on the machine’s table. They compensate for the workpiece’s .Machine coordinate systems are essential for precision and efficiency in CNC machining. Understanding the different types of coordinate systems and their applications empowers .

Machine coordinate systems are defined by the geometry of the CNC machine. The machine “knows” where it is within its own coordinate system by a series of limit switches and encoders that are located on each of the axes.

You know that G90 specifies the absolute mode. Any coordinates specified after G90 will use the program zero point as the origin for the motion. This is the most common method of specifying coordinates in your program - from program zero.G91, as you also know, specifies incremental mode. Any coordinates specified after G91 will use the machine's current position .Coordinate System Rotation: CSR matches the machine to your vise This option is made specifically for the machinist who is constantly breaking down and setting up new fixtures and vises. By simply touching off two points along the edge of .

A CNC machine cannot be successfully operated without an understanding of the how coordinate systems are defined in CAM and CNC machine and how the systems work together. This lesson begins with a review of the Cartesian . Coordinate system and direction of motion 1. The principle of determining the coordinate system. 1) The principle of the tool moving relative to the stationary workpiece This principle stipulates that regardless of whether the CNC machine tool is a tool movement or a workpiece movement, the program is written based on the tool's trajectory during .In addition to the machine coordinate system, CNC milling machines often support multiple work coordinate systems (WCS). A WCS allows the operator to set additional origins for specific features or operations on the workpiece without changing the machine’s coordinate system. This feature is useful when machining multiple features on different .Setting Up CNC Lathe Coordinate System. Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment. First and foremost is the establishment of the machine reference point.

Can you please explain the differences?Response:These coordinate systems provide three different ways to track the machine's movements. Each has a different point of reference - or origin.AbsoluteWith the absolute coordinate system (shown on the absolute position display screen), the origin is the currently active program zero point. If fixture offset number . In the right-hand coordinate system, a clockwise rotation around the Z-axis will cross the X-axis first and then the Y-axis. The right-hand coordinate system is commonly used with CNC Routers. Planes. The cutting area of a CNC Router is like a cube. Each side of the cube is a plane made up of two axes, X-Y, Y-Z, or X-Z.

understanding cnc offsets

The machine datum M is a defined position in the machine coordinate system. Since the position of the machine datum M is independent of the axis positions and the workpiece position, the machine datum M is used as a reference point for constant positions.The core of any CNC machine operation,whether it's milling,turning,or a plasma cutting machine,is the precise movement in a specified path – and that–s where the coordinate system comes into play. CNC machines use coordinate systems for direction and distances to control the machine's movements accurately.This coordinate system is called the machine coordinate system. It is a default coordinate system. The CNC machine will use the machine or default coordinate system to send the spindle to machine home. Operators do not set, reset, or choose machine coordinate systems. Machine coordinate systems are defined by the geometry of the CNC machine. Coordinate system and direction of motion 1. The principle of determining the coordinate system. 1) The principle of the tool moving relative to the stationary workpiece This principle stipulates that regardless of whether the CNC machine tool is a tool movement or a workpiece movement, the program is written based on the tool’s trajectory during .

By implementing and maintaining accurate machine coordinate systems, CNC operators can unlock higher levels of productivity, quality, and customer satisfaction in their manufacturing operations. With the continuous advancements in technology, it is exciting to anticipate the future developments in CNC machining and the role that machine .

An NC Machine stands for Numerical Control Machine it is the predecessor of CNC Machine. It is a manufacturing equipment wherein the Operator doesn’t manually adjust parameters. The parameters like Depth of the cut, Feed Rate, speed, etc. . The machine manufacturer sets a permanent reference system called the machine coordinate system . All CNC machines run off NC codes, which include coordinates. The WCS—which is X, Y, and Z—is in the middle of the component. These coordinates drive the toolpath, and are referenced from the WCS. . Work Coordinate System to the Machine. How does this translate to the machine? In the video, the WCS is set on a vertical mill. You may know .33 - Coordinate System. This setting changes the way the Haas control recognizes the work offset system when a G52 or G92 is programmed. It can be set to FANUC or HAAS.. Set to FANUC with G52:. Any values in the G52 register are added to all work offsets (global coordinate shift). This G52 value can be entered either manually or through a program. When FANUC is selected, . In this episode of Machining Fundamentals, we'll cover everything you need to know about the Work Coordinate System — what it is, why we need it, and how we .

Displays current active coordinate system. You can select active coordinate system either using the standard coordinate system G-codes G54,G55,G56.. or using Machine/Coordinate System/Select feature.The machine coordinate system (MCS) is defined by the applied kinematics which determine its position and orientation. The decoder coordinate system (DCS) is managed by the interpreter (SMC_NCInterpreter function block instance). All coordinate information for motion commands are interpreted in this coordinate system.

@G-Code Tutor talks about the differences between cartesian and polar coordinates systems and explains when to use each when programming CNC machines. When programming CNC machine tools, there are two coordinate systems that can be used to identify the position of the tool or of the features of your part: the Cartesian system and the polar system. The ISO unified standard right-hand Cartesian coordinate system is used by CNC machine tools. The nomenclature of the machine axes is depicted below; three axes are parallel to one another, and the three fingers of each axes point in the positive directions of the X-axis, Y-axis, and Z-axis. Additionally, when a machine tool moves in more than . G53 is a G-code command that tells a CNC machine to move to a position relative to the machine coordinate system. The machine coordinate system is a fixed reference frame that is defined by the physical limits of the machine. It is also known as the machine home position or the machine zero point. The machine coordinate system is usually set by .

Hello friends,In this video we will discuss about CNC coordinates system. What is coordinates system .How to working Absolute coordinates, Incremental Coordi.

Coordinate system in CNC Router is a way to determine the position, direction and motion of the machine table, work piece, machine tool on X-axis, Y-axis, and Z-axis. . Machine Coordinate System "Coordinate system" is a terminology that is used to .

Correct it’s a four axis machine (once I put the fourth axis on the table!). I just needed to synchronize the machine coordinate system with the work coordinate system. On this machine it looks at the machine coordinate system and references the work coordinate system to that setting. I just needed to figure out how to get them to both be the . Due to the rough nature of surfaces produced by current additive metal processes, a deviation between the nominal and actual pose of the part arises when fixturing in an NC machine. Modern 3D scanning systems are capable of generating high density measurements that may be used to localize the part and compensate for these errors; but require that scan . Comment une Machine CNC Utilise-t-elle les Coordonnées . En utilisant le système de coordonnées cartésiennes, nous contrôlons les mouvements des machines CNC le long de chaque axe afin de transformer un bloc de matériau en une pièce finie. Bien qu’il soit difficile de décrire les axes en termes relatifs, on obtient généralement les .

Wagner Machine specializes in various manufacturing capabilities including .

machine coordinate system cnc|cnc machine axis locations diagram