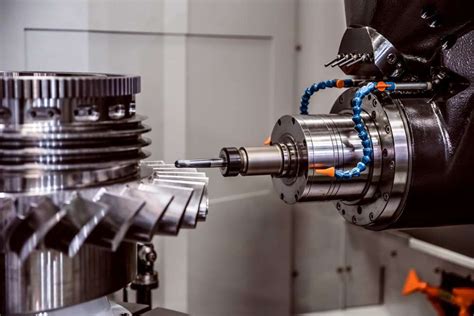

cnc lathe machine advantages and disadvantages Advantages of CNC lathes include reduced labor costs, increased productivity, and improved quality control. Disadvantages may include higher upfront costs and the need for specialized training or programming skills. Junction box type electrical enclosures are designed and built meet JIC standards. This smaller enclosure is typically used for terminal block junction points in field applications.

0 · horizontal cnc lathe disadvantages

1 · disadvantages of cnc lathe machine

2 · different types of cnc lathe

3 · cnc lathe pros and cons

4 · cnc lathe advantages and disadvantages

In the distribution box, commonly known as the distribution board or breaker panel, you’ll find several critical components responsible for managing and distributing electrical power throughout a building or home.

horizontal cnc lathe disadvantages

One of the most important advantages of CNC lathe is its ability to operate continuously without needing constant manual intervention. This translates into the production of parts that have precise dimensions, ensuring .

One of the most important advantages of CNC lathe is its ability to operate continuously without needing constant manual intervention. This translates into the production of parts that have precise dimensions, ensuring that every piece meets high standards.

Advantages of CNC lathes include reduced labor costs, increased productivity, and improved quality control. Disadvantages may include higher upfront costs and the need for specialized training or programming skills.High precision and accuracy – CNC lathes craft parts with exact measurements and fine details, ensuring every piece matches the desired specifications. Consistent quality output – They produce items that are exactly alike, making sure each product is as good as the last.

Discover the advantages and disadvantages of using a CNC lathe machine, including precision, productivity, and potential costs involved. Some of the advantages in using a lathe machine are: High Productivity – The industries that are using lathe machines can be sure that these produce high quality products with top-notch accuracy, especially the CNC lathe machines. As a result, the productivity will increase. Uncover the key CNC lathe machine advantages and disadvantages to boost your manufacturing processes. Stay informed for better operational decisions. CNC lathe machining can now be said to be a very popular processing technology. Compared with ordinary lathes, CNC lathes between the two are more likely to highlight its advantages. Let's analyze the advantages and disadvantages of these comparisons. 1. Higher procurement costs.

disadvantages of cnc lathe machine

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.Lathe machines are versatile tools used for a variety of applications. Advantages include increased accuracy and improved safety. Disadvantages include high initial cost and limited maneuverability.CNC machining offers several significant advantages over traditional manufacturing methods. 1. High Precision and Accuracy. CNC machines utilize computer-controlled motion to ensure incredibly tight tolerances. This level of precision is repeatable, making CNC machining ideal for high-volume production.

One of the most important advantages of CNC lathe is its ability to operate continuously without needing constant manual intervention. This translates into the production of parts that have precise dimensions, ensuring that every piece meets high standards.Advantages of CNC lathes include reduced labor costs, increased productivity, and improved quality control. Disadvantages may include higher upfront costs and the need for specialized training or programming skills.High precision and accuracy – CNC lathes craft parts with exact measurements and fine details, ensuring every piece matches the desired specifications. Consistent quality output – They produce items that are exactly alike, making sure each product is as good as the last.

Discover the advantages and disadvantages of using a CNC lathe machine, including precision, productivity, and potential costs involved.

Some of the advantages in using a lathe machine are: High Productivity – The industries that are using lathe machines can be sure that these produce high quality products with top-notch accuracy, especially the CNC lathe machines. As a result, the productivity will increase. Uncover the key CNC lathe machine advantages and disadvantages to boost your manufacturing processes. Stay informed for better operational decisions. CNC lathe machining can now be said to be a very popular processing technology. Compared with ordinary lathes, CNC lathes between the two are more likely to highlight its advantages. Let's analyze the advantages and disadvantages of these comparisons. 1. Higher procurement costs.

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.Lathe machines are versatile tools used for a variety of applications. Advantages include increased accuracy and improved safety. Disadvantages include high initial cost and limited maneuverability.

different types of cnc lathe

cnc lathe pros and cons

kaiser aluminum fabricated products llc

Sheet metal hemming is a standard method for improving the quality and appearance of your sheet metal products. This article discusses the principle behind sheet metal hemming, its purpose, and how you can get the best from it.

cnc lathe machine advantages and disadvantages|different types of cnc lathe