bulk deformation processes and sheet metal processes This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal . This guide will help you understand what is a junction box is and get the best possible junction box for yourself without any struggle when you need one. Follow the instructions, and you’ll soon find a reliable junction box!

0 · metal deformation process

1 · material deformation process

2 · manufacturing deformation process

3 · load estimation for bulk forming

4 · bulk metal deformation

5 · bulk forming process

6 · bulk deformation vs metal forming

7 · bulk deformation process

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and the specific techniques .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and .This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to .

There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire .Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to .

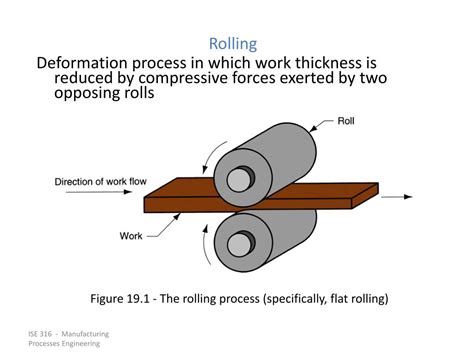

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion .

hold it mate medium steel planter box bracket kit

–Primary processes reduce a cast material into slabs, plates, and billets –Secondary processes reduce shapes into finished or semifinished products •Bulk deformation processes are those .Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to deform it. • It is used to make a variety of high-strength components for automotive, aerospace, and other applications.There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire drawing, extrusion, deep drawing, and bending.Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.

Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion –work is squeezed through a die opening, thereby taking the shape of the opening 4. Wire and bar drawing –diameter of wire or bar is

–Primary processes reduce a cast material into slabs, plates, and billets –Secondary processes reduce shapes into finished or semifinished products •Bulk deformation processes are those processes where the thickness or cross sections are reduced •Sheet-forming operations involve the deformationBulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.

Bulk forming processes Forging • It is a deformation process in which the work piece is compressed between two dies, using either impact load or hydraulic load (or gradual load) to deform it. • It is used to make a variety of high-strength components for automotive, aerospace, and other applications.There are three types of metal forming processes: bulk metal forming, sheet metal forming, and sheet-bulk metal forming. Some popular metal forming processes are forging, rolling, wire drawing, extrusion, deep drawing, and bending.Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

These interactions are demonstrated by selected examples of both bulk and sheet metal forming. In this connection special processes, such as superplastic forming, thermomechanical.

Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion –work is squeezed through a die opening, thereby taking the shape of the opening 4. Wire and bar drawing –diameter of wire or bar is

metal deformation process

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel .

bulk deformation processes and sheet metal processes|bulk deformation vs metal forming