discrete manufacturing for custom to order parts Discrete manufacturing is the assembling and production across several workstations located on an assembly line, also called a production line, which produces distinct components, parts, materials or subassemblies that . In this blog post, we will explore the most common file formats used by CNC machines and their importance in the manufacturing process. Introduction. To understand why file formats are crucial for CNC machines, we need to grasp the basic concept behind CNC technology.

0 · discrete manufacturing vs repetitive manufacturing

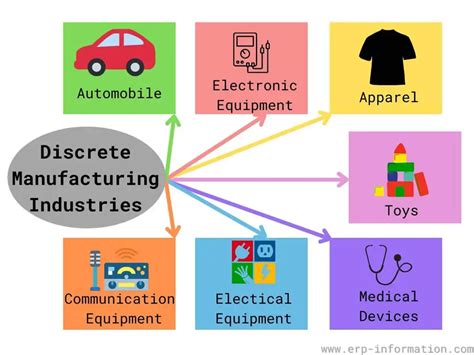

1 · discrete manufacturing process manufacturing

2 · discrete manufacturing industry examples

$1,799.95

Discrete manufacturing is the assembling and production across several workstations located on an assembly line, also called a production line, which produces distinct components, parts, materials or subassemblies that .

A discrete manufacturing process is a manufacturing method for creating specific, individual products that we can see and count. Those products are typically made of several components or sub-assemblies parts – for example, toys, cars, and .

discrete manufacturing vs repetitive manufacturing

discrete manufacturing process manufacturing

Discrete manufacturing enables companies to tailor products to meet specific customer requirements, fostering customization and flexibility in production. With rigorous quality control measures and precise assembly . Customization: Discrete manufacturing lends itself well to customization, as it involves the assembly of distinct parts. This means that variations can be introduced into the process to create products that are . Discrete manufacturing is a manufacturing practice that operates with bill of materials (BOM) to make individual parts of a product. The pieces are then merged together to form the final product at the end of production. Discrete manufacturing is the assembling and production across several workstations located on an assembly line, also called a production line, which produces distinct components, parts, materials or subassemblies that are put together at the end of the production cycle into finished products.

A discrete manufacturing process is a manufacturing method for creating specific, individual products that we can see and count. Those products are typically made of several components or sub-assemblies parts – for example, toys, cars, and airplanes. Companies that follow make-to-order, make-to-stock or assemble-to-order production practices use discrete manufacturing. For example, a company that produces custom furniture may allow its customers to mix and match a wide variety of colors, shapes and materials. Discrete manufacturing enables companies to tailor products to meet specific customer requirements, fostering customization and flexibility in production. With rigorous quality control measures and precise assembly processes, discrete manufacturing ensures the consistent delivery of high-quality products. Customization: Discrete manufacturing lends itself well to customization, as it involves the assembly of distinct parts. This means that variations can be introduced into the process to create products that are tailored to specific customer requirements.

Discrete manufacturing is a manufacturing practice that operates with bill of materials (BOM) to make individual parts of a product. The pieces are then merged together to form the final product at the end of production.Discrete manufacturing assembles final products that represent distinct, individual units. These could be as simple as a fastener or as complex as a smartphone or aircraft. There are several core elements involved in discrete manufacturing: A bill of materials (BOM) represents all the individual parts or components that make up a discrete unit . What is Configure To Order (CTO)? A Configure to Order (CTO) system is a hybrid of make to stock and make to order operations. It is a set of components (sub-assemblies) that are built to stock whereas the end products are assembled to order. . By keeping inventory at the component level, customer orders can be filled quickly.

Discrete manufacturing is an industry term for the manufacturing of finished products that are distinct items capable of being easily counted, touched or seen. Discrete manufacturing involves parts and systems like nuts and bolts, brackets, wires, assemblies and individual products. Make to Order is when an assembly project has to be done of parts and sub-assemblies according to the specific requirements of a specific customer/sales order. Such an assembly may or may not be used again for sales orders from other customers. Discrete manufacturing is the assembling and production across several workstations located on an assembly line, also called a production line, which produces distinct components, parts, materials or subassemblies that are put together at the end of the production cycle into finished products.

A discrete manufacturing process is a manufacturing method for creating specific, individual products that we can see and count. Those products are typically made of several components or sub-assemblies parts – for example, toys, cars, and airplanes. Companies that follow make-to-order, make-to-stock or assemble-to-order production practices use discrete manufacturing. For example, a company that produces custom furniture may allow its customers to mix and match a wide variety of colors, shapes and materials. Discrete manufacturing enables companies to tailor products to meet specific customer requirements, fostering customization and flexibility in production. With rigorous quality control measures and precise assembly processes, discrete manufacturing ensures the consistent delivery of high-quality products. Customization: Discrete manufacturing lends itself well to customization, as it involves the assembly of distinct parts. This means that variations can be introduced into the process to create products that are tailored to specific customer requirements.

discrete manufacturing industry examples

Discrete manufacturing is a manufacturing practice that operates with bill of materials (BOM) to make individual parts of a product. The pieces are then merged together to form the final product at the end of production.Discrete manufacturing assembles final products that represent distinct, individual units. These could be as simple as a fastener or as complex as a smartphone or aircraft. There are several core elements involved in discrete manufacturing: A bill of materials (BOM) represents all the individual parts or components that make up a discrete unit . What is Configure To Order (CTO)? A Configure to Order (CTO) system is a hybrid of make to stock and make to order operations. It is a set of components (sub-assemblies) that are built to stock whereas the end products are assembled to order. . By keeping inventory at the component level, customer orders can be filled quickly.Discrete manufacturing is an industry term for the manufacturing of finished products that are distinct items capable of being easily counted, touched or seen. Discrete manufacturing involves parts and systems like nuts and bolts, brackets, wires, assemblies and individual products.

Don't ground to the electrical box. Connecting the ground wire to a metal electrical box will energize the box in the event of a short circuit. The box could overheat and start a fire, or someone could get a shock from touching it.

discrete manufacturing for custom to order parts|discrete manufacturing process manufacturing