dimple in sheet metal A simple demonstration of laying out, drilling and pressing dimpled lightening holes with dimple dies in a steel bumper.

What Is The Purpose Of A Junction Box? A junction box is an enclosure for electrical connections, protecting them from weather and preventing electric shocks. How Do I Know If I Need A Junction Box?

0 · sheet metal minimum bend length

1 · sheet metal extruded hole design

2 · sheet metal extruded hole

3 · sheet metal dimple dies

4 · sheet metal basic design guidelines

5 · minimum flange length sheet metal

6 · how to use dimple dies

7 · hole to distance sheet metal

Discover over 50 incredible ideas for what you can create using a CNC machine. Unleash your creativity and dive into the world of limitless possibilities. Get ready to be amazed!

sheet metal minimum bend length

aluminum electric hot box

sheet metal extruded hole design

Making Dimples in Sheet Metal Without Dimple Dies - Fabrication That Doesn't Suck. Today we look at using what you already have in your shop to make basic d. Sheet metal dimple forming improves strength-to-weight ratios, increase rigidity, and enhance the visual appeal of metal parts. Here's a simple sheet metal how to video for making dimples in panels. No expensive tooling was used. Why spend the money if you don't have to?Please consi.

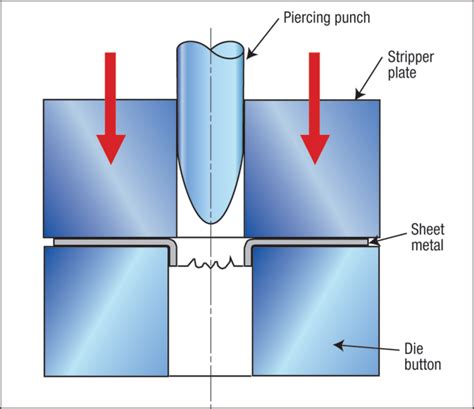

Learn how to use dimple dies effectively to achieve professional results in metal fabrication. This comprehensive guide provides expert tips, step-by-step instructions, and . Dimpling in sheet metal is the process of creating holes on the sheet metal materials, which resemble the shape of dimples. These uniquely-shaped holes are useful for you to use as strong panels for your sheet metal . A simple demonstration of laying out, drilling and pressing dimpled lightening holes with dimple dies in a steel bumper.

Losing weight without compromising strength is a constant battle in motorsports, and dimple dies are one proven way to achieve both. Let’s make a Dimple. DIMPLE. The Dimple requires two things: a sheet metal panel and a closed loop sketch (or some other region area). The interface for the Dimple has the CommandBar shown to the right and the .

aluminum cnc milling machine part suppliers

Dimples can reduce the weight of gussets significantly by removing material. Dimple dies have 4 main uses: Make flimsy sheetmetal stronger: By adding a bunch of flared holes to a piece of steel or aluminum you can .Making Dimples in Sheet Metal Without Dimple Dies - Fabrication That Doesn't Suck. Today we look at using what you already have in your shop to make basic d. Sheet metal dimple forming improves strength-to-weight ratios, increase rigidity, and enhance the visual appeal of metal parts. Here's a simple sheet metal how to video for making dimples in panels. No expensive tooling was used. Why spend the money if you don't have to?Please consi.

A Dimple Die Set is an essential tool for metalworking, designed to create precise dimples in sheet metal. This technique enhances both the strength and aesthetic appeal of the material, making it a favorite among fabricators and hobbyists alike. Learn how to use dimple dies effectively to achieve professional results in metal fabrication. This comprehensive guide provides expert tips, step-by-step instructions, and answers to common questions on using dimple dies for various applications. Dimpling in sheet metal is the process of creating holes on the sheet metal materials, which resemble the shape of dimples. These uniquely-shaped holes are useful for you to use as strong panels for your sheet metal components.

A simple demonstration of laying out, drilling and pressing dimpled lightening holes with dimple dies in a steel bumper.

Losing weight without compromising strength is a constant battle in motorsports, and dimple dies are one proven way to achieve both.

Let’s make a Dimple. DIMPLE. The Dimple requires two things: a sheet metal panel and a closed loop sketch (or some other region area). The interface for the Dimple has the CommandBar shown to the right and the Dimple Options dialog shown below. All of these settings are pretty easy to understand, and self-explanatory.

Dimples can reduce the weight of gussets significantly by removing material. Dimple dies have 4 main uses: Make flimsy sheetmetal stronger: By adding a bunch of flared holes to a piece of steel or aluminum you can strengthen it significantly.

Making Dimples in Sheet Metal Without Dimple Dies - Fabrication That Doesn't Suck. Today we look at using what you already have in your shop to make basic d. Sheet metal dimple forming improves strength-to-weight ratios, increase rigidity, and enhance the visual appeal of metal parts. Here's a simple sheet metal how to video for making dimples in panels. No expensive tooling was used. Why spend the money if you don't have to?Please consi.A Dimple Die Set is an essential tool for metalworking, designed to create precise dimples in sheet metal. This technique enhances both the strength and aesthetic appeal of the material, making it a favorite among fabricators and hobbyists alike.

Learn how to use dimple dies effectively to achieve professional results in metal fabrication. This comprehensive guide provides expert tips, step-by-step instructions, and answers to common questions on using dimple dies for various applications.

Dimpling in sheet metal is the process of creating holes on the sheet metal materials, which resemble the shape of dimples. These uniquely-shaped holes are useful for you to use as strong panels for your sheet metal components. A simple demonstration of laying out, drilling and pressing dimpled lightening holes with dimple dies in a steel bumper.Losing weight without compromising strength is a constant battle in motorsports, and dimple dies are one proven way to achieve both.

Let’s make a Dimple. DIMPLE. The Dimple requires two things: a sheet metal panel and a closed loop sketch (or some other region area). The interface for the Dimple has the CommandBar shown to the right and the Dimple Options dialog shown below. All of these settings are pretty easy to understand, and self-explanatory.

Yellow crisscross lines mark a box junction. Their purpose is to keep the junction clear by preventing traffic from stopping in the path of crossing traffic. You MUST NOT enter a box junction unless your exit road is clear.

dimple in sheet metal|how to use dimple dies