bent sheet metal manufacturing Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a . There’s a different vibe to the [metal] genre. The industry as a whole seems to crave authenticity and then in the metal world, it’s like a dirty secret to let people know that you have a job in a bar when you come off tour.

0 · types of bending sheet metal

1 · sheet metal cutting and bending

2 · sheet metal bending near me

3 · sheet metal bending dies

4 · maximum thickness sheet metal bending

5 · hand bending sheet metal

6 · bending tool for sheet metal

7 · bending galvanized sheet metal

We're updating the user interface in Sonar to be even more convenient than before — now all your favorite presets figure at the main screen, so you can instantly see which ones are applied! Sonar, part of the free SteelSeries GG software, serves to be your all-in-one command center for game audio.

Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .

Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with .Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

types of bending sheet metal

Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision . Bending is an important process in sheet metal fabrication process. In this guide, I will explain everything you should know about sheet metal bending process. If you want to be an expert in metal bending parts, read this guide to . Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.

cnc laser cutting machine for stainless steel

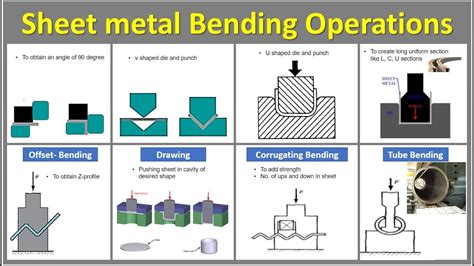

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final . Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with complex geometries, they usually turn to CNC machining, stamping, or forging for their metal parts.

sheet metal cutting and bending

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision and efficiency. Bending is an important process in sheet metal fabrication process. In this guide, I will explain everything you should know about sheet metal bending process. If you want to be an expert in metal bending parts, read this guide to the end.

Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final .

Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with complex geometries, they usually turn to CNC machining, stamping, or forging for their metal parts.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision and efficiency.

cnc laser engraving machine manufacturers in china

sheet metal bending near me

cnc laser cutting machines suppliers

cnc laser cutting machine usa

You should use Sonar if you got into EQing and balancing with the new audio system. Most games automatically detects which source to use. Gaming/Chat/Media etc.

bent sheet metal manufacturing|bending galvanized sheet metal