bending thin sheet metal Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . When using junction boxes to extend ring mains or radial circuits, remember that the regulations limit the length of cable for both ring and radial circuits, and also how spurs are connected to ring mains. These regulations must be adhered to to avoid possible overloading the electrical wiring. Junction boxes should always be fixed . See more

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Box junctions: what are they? A box junction is outlined by a perimeter containing intersecting yellow lines in a grid pattern. They are designed to prevent gridlock by.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See moreThis guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are . If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

types of bending sheet metal

sheet metal bending standards

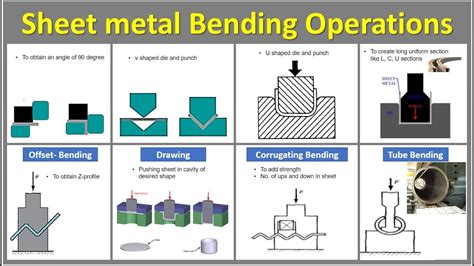

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .

In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's how to easily bend thin-gauge sheet metal. Sheet metal is a thin, malleable piece of metal. Since it’s so thin, you can bend it and it will keep its shape. To bend sheet metal, you simply need to squeeze it between parts . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

partes de un equipo de soldadura mig

sheet metal bending near me

parts cnc machining service

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's how to easily bend thin-gauge sheet metal.

sheet metal bending guidelines

part 1 ot the witchcraft cad cam-cnc board production system

Clear technical distinctions exist between junction boxes and pull boxes in electrical systems. These differences affect their applications, installation requirements, and overall project costs. Let’s break down each type to help you make informed decisions.

bending thin sheet metal|sheet metal bending guidelines