swarf removal in cnc machine Efficient swarf removal is a critical aspect of CNC machining that should not be overlooked. By implementing appropriate swarf removal techniques and practices, manufacturers can . $3.30

0 · swarf removal techniques

1 · swarf metalworking

2 · swarf machine safety

3 · swarf equipment

4 · how to use swarf

5 · how to handle swarf

6 · cnc swarf washdown

7 · cnc swarf removal

We would like to show you a description here but the site won’t allow us.

swarf removal techniques

Efficient swarf removal is a critical aspect of CNC machining that should not be overlooked. By implementing appropriate swarf removal techniques and practices, manufacturers can .

Gio Albanese: Ben, today we're going to take a closer look at your Swarf Management Systems and conveyors and the innovation behind them, and how they've evolved over the years. Ben Crowther:.

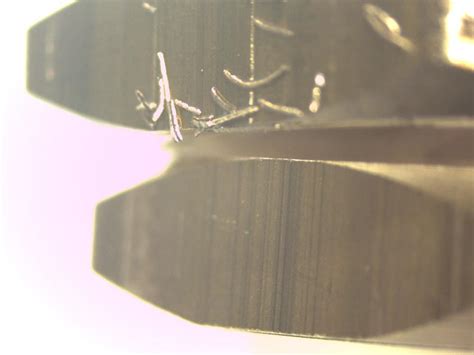

In this article, we'll explore how efficient swarf handling can drastically reduce machine downtime. You'll learn about best practices, practical solutions, and strategies to streamline swarf management, ultimately boosting . Boring process needs to be stopped and stringy nest of swarf removed every 15" of boring depth. The operator goes in with a hooked stick and fishes out the swarf. Has anyone .

Swarf removal for Vertical CNC machines demo in Haas VF4SS. .more.In this blog post, we'll explore the importance of having an efficient swarf removal system in place and how it can streamline CNC machine efficiency. We'll discuss the types of swarf removal . This video will add value to the knowledge of Diploma/ Engineering students in regards to swarf removal in CNC machines. Swarf removal is a basic machining process in which material is removed or cut by using relative movements between the tool and the workpiece to be machined. In other words, the desired final shape of the workpiece (e.g. .

swarf metalworking

Ben discusses the benefits of the new Cromar Swarf Management Technologies and Products. Gio Albanese: Ben, today we're going to take a closer look at your Swarf .The Swarf Unlimited All-In-One Conveyor is the ultimate solution to your CNC machine swarf removal needs! This powerful conveyor is equipped with advanced features that ensure a clean and efficient production process. The All-In-One . This video will add value to the knowledge of Diploma/ Engineering students in regards to swarf removal in CNC machines.

Cleaner and better performing machine pumps avoiding blockages and expensive machine downtime; Tank cleaning with sludge and swarf removal; Cost savings for emulsion buy-back; Saving on waste recovery (in case of . Aid with removal of swarf and used coolant from your CNC machines in a cost effective and time saving manner. Full-Service Cleaning of CNC Machines to Maintain High Performance. . Our service begins with advanced vacuum removal of all liquids, metal shavings, and other contaminants. Utilizing our fleet of 3,800-gallon vacuum trucks equipped .For faster drilling and improved swarf removal, ROBODRILL enables through-spindle coolant of up to 70 bar. Superb surfaces, superior part quality FANUC ROBODRILL vertical machining centre lets you achieve superior parts quality using CNC functions such as Nano interpolation, 3-D machining or AI contour control.

Hi, We are finish boring stainless parts up to 80" long, with through hole already machined, internal dia is approx 4", straight bore. We finish bore from both ends, ie 40" of bore depth. Boring process needs to be stopped and stringy nest of .

The Clean•Tec chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the . This enhances the cleaning effect and makes perfect sense if pockets and bores are commonly packed with swarf. . the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling .Haas CNC Chip Clearing Fans are the perfect complimentary tools for all CNC users, big and small, for short runs or production. They are engineered to provide the best results possible, when it comes to removing machined material chips, coolant, and other debris from your workpiece or fixture. . (if the machine is equipped) to pre-clean large .Chips or dust generated in the machining chamber (22) of a machine-tool (12) are removed by a current of suction air. The chamber is encapsulated airtight, the current (27) being directed in bundled form across it. The current can be inclined downwards from the top, and compressed-air can also be directed at the machining position roughly in the same direction as the suction .

Cromar are a major European manufacturer of Swarf Conveyors and Filtration solutions for the engineering, aerospace and rail industries, and also offer conveyor spare parts and a conveyor repairs service. The Slat/Hinge conveyor is a general purpose swarf conveyor for general machining applications, Any chip size/shape, Wet and dry applications, CNC turning centres, . Oh, Diamond Machiners are notorious for taking their machines to bits and tinkering with them. be careful if you leave the enclosures off when machining Aluminium as the swarf conducts electricity and can short out boards etc. Anyways! nice to meet you

Why Swarf Removal Matters . Swarf removal is essential for several reasons. Firstly, it helps to prevent damage to the CNC machine. Swarf can accumulate in a machine's nooks and crannies, causing clogs and potentially damaging mechanical components. Secondly, efficient swarf removal increases productivity by reducing downtime for cleaning and .GM Meccanica performs various processes by light alloys swarf removal with CNC 5-axis milling machine with working areas up to 6m long for a linear width of 0.6mt. The technology of the light alloys swarf removal sector also includes: - 3 fresatrici CNC 5 assi campo di lavoro 6×0.6ml. – Fresatrice CNC 3 assi campo di lavoro 6×0.6ml.

swarf removal in cnc machine. CNC boring mills .

swarf machine safety

A quick and easy way to remove coolant and swarf chips from your work piece and table before opening the machine door. Supplied with 2 coolant holes to support the removal of chips when required. Perfect addition to support an unmanned automation setup. Okay running into the cooling/SWARF problem and looking at options and they are as follows: Designing a plate to go on the machine to allow SWARF being directly sucked up and hoping the air flow provides some indirect air cooling (not the best option but gets swarf out of the way). Getting input on designing a compressor based (type to be determined within a budget) . A CNC machine tool always has a sliding table and a spindle to control the position and speed. The table of the machine is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction. Driving System. The driving system of a CNC machine includes an amplifier circuit, drive motors, and ball lead screws.The advantages of recirculating ball screws over Acme screws are: (1) longer life (2) less frictional resistance (3) lower torque required (4) more precise positioning of slides because backlash is almost completely eliminated Unit 11 13 Trade of Metal Fabrication – Phase 2 Module 4 Unit 11 Figure 3 - Re-circulating Ball Leadscrew Machine .

Kiểu sàn nhàm chán; Kiểu lập kế hoạch nhàm chán; Máy doa ngang ( Loại bàn) Trung tâm máy CNCمركز آلة القنطرية العملاقة . مخرطة ذات عمود مزدوج; مخرطة عمودية بمحور cJULIUS offers different modules for swarf removal such as swarf hopper, swarf shredder, conveyor belts, swarf deflecting guides and others. Swarf hopper. A swarf hopper can be integrated into strip edge trimming machines. The swarfs are fed to a shredder through a swarf hopper and finally removed via a conveyer belt. Swarf shredderHowever for CNC machines swarf build-up is a problem due to the high rates of metal removal and the fact that CNC machines may not have an operator present during machining. Therefore in CNC machines have built in swarf removal equipment such as rotary screw or linear conveyors. Slanted beds in CNC lathes allow swarf to fall away into the base .

Accumulated shavings in a machine can cause issues like overheating, contamination, and potentially be a fire hazard. Conveyors, vacuums, or blowers help with chip removal. The metal shavings can be stored safely in bins, bags, or containers, awaiting recycling. . As these industries continue to use CNC, swarf will continue to have immense .

swarf equipment

metal slatwall brackets

When it comes to waterjet cutting in Atlanta or any other type of service for cutting metal or metal products, you can count on Wallace Sheet Metal to provide a level of quality others can’t match.

swarf removal in cnc machine|swarf equipment