electrical code box size One of the mistakes often made is over loading an wire electrical box with too many wires. This will cause switches and outlets to not fit correctly and could even cause wires to become damaged. This information will help you plan . The weight of a stainless steel sheet can be calculated using the formula: \[ \text{Weight} = \frac{\text{Thickness (mm)} \times \text{Width (mm)} \times \text{Length (mm)} \times \text{Density of Stainless Steel (kg/m}^3\text{)}}{10^6} \] Given the density of stainless steel is approximately 7850 kg/m³. Example Calculation

0 · nec code for electrical boxes

1 · nec code for box size

2 · electrical junction box nec code

3 · electrical junction box code

4 · electrical code for vac box

5 · electrical code for box fill capacity

6 · electrical box size chart

7 · electrical box codes

hello. I'm new to this forum. I'm a novice welder looking for some advice on oxy-acetylene welding 18 gauge mild steel. My project involves try to weld a 4" ribbon of steel around a curved panel about 18" in diameter. I'm trying to make some interesting shaped neon clocks. (Neon glass-bending is my main trade.) All of the welding is outside corner.

One of the mistakes often made is over loading an wire electrical box with too many wires. This will cause switches and outlets to not fit correctly and could even cause wires to become damaged. This information will help you plan . Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and .Selecting the appropriate junction box size is a critical task for facility managers and electricians to ensure safety, compliance, and efficient functionality of electrical systems. The National Electrical Code (NEC) 2023 provides detailed .

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Finding out how much volume of an electrical box you need to use is easy. However, it's necessary to do so that we follow the electrical building code to avoid potential danger and fire hazards. The NFPA® presents the use .

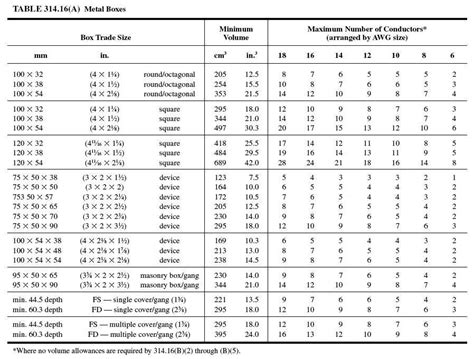

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to . Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), .

Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be .

One of the mistakes often made is over loading an wire electrical box with too many wires. This will cause switches and outlets to not fit correctly and could even cause wires to become damaged. This information will help you plan your electrical box size properly. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Selecting the appropriate junction box size is a critical task for facility managers and electricians to ensure safety, compliance, and efficient functionality of electrical systems. The National Electrical Code (NEC) 2023 provides detailed guidelines to help professionals make informed decisions.

behind wall junction box

nec code for electrical boxes

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Finding out how much volume of an electrical box you need to use is easy. However, it's necessary to do so that we follow the electrical building code to avoid potential danger and fire hazards. The NFPA® presents the use of "volume allowances" in determining the total box fill we would need for a utility box.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B). Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be necessary to perform box-fill calculations. These are covered in National Electrical Code (NEC) sections 314.16(A) and 314.16(B).

One of the mistakes often made is over loading an wire electrical box with too many wires. This will cause switches and outlets to not fit correctly and could even cause wires to become damaged. This information will help you plan your electrical box size properly.

Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Selecting the appropriate junction box size is a critical task for facility managers and electricians to ensure safety, compliance, and efficient functionality of electrical systems. The National Electrical Code (NEC) 2023 provides detailed guidelines to help professionals make informed decisions. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Finding out how much volume of an electrical box you need to use is easy. However, it's necessary to do so that we follow the electrical building code to avoid potential danger and fire hazards. The NFPA® presents the use of "volume allowances" in determining the total box fill we would need for a utility box.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B).

nec code for box size

bell weatherproof electrical box drawing

Weaver Metal Fab is a fabricated metal products manufacturer located in .

electrical code box size|electrical box size chart