extruded hole in sheet metal Hole extrusions start with a punched hole in a flat surface of the sheetmetal. Then an extruding punch expands the hole to the required ID, usually in one hit. The extrusion wall height is the result of the punched hole diameter, . $8.18

0 · sheet metal rib design guidelines

1 · sheet metal hole extrusion tool

2 · sheet metal extruded hole design

3 · sheet metal bend relief guidelines

4 · metal fabrication draw form

5 · hole to distance sheet metal

6 · hole extrusion calculator

7 · extrude and tap sheet metal

Black Durable U-Clamps Metal Pipe Clamps Double Hole Double Hole Pipe Strap DIY U-Bracket (Pack of 6) (1/2 INCH) Application: They are ideal for pipe straps. These U-clamps are strong enough to hold pipes or rods securely in place.The U-shaped, two-hole design allows for easy installation on wood, drywall, exterior walls, floors, and other panels.

Hole extrusions start with a punched hole in a flat surface of the sheetmetal. Then an extruding punch expands the hole to the required ID, usually in one hit. The extrusion wall height is the result of the punched hole diameter, .

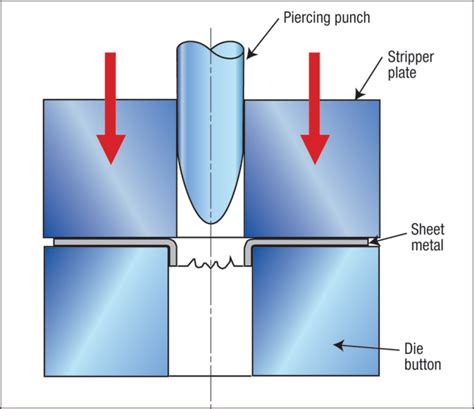

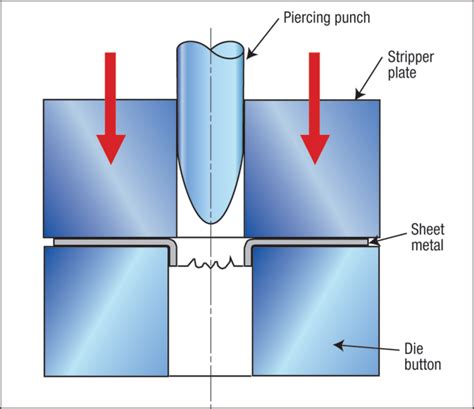

Creating an extruded hole using a punching process requires extreme pressure/Force. Extruded holes very close to the part edge can lead to sheet metal deformation or tearing. Therefore the minimum distance between the .Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to .

UniPunch tooling can be used to simultaneously punch a hole and extrude the material down. Applications include for self-tapping sheet metal screws or, in .

An extruded hole is one that is generated at one station using a specially stepped punch that first shears a smaller hole and then follows through to deform the local area around the hole into a . Extruding a hole sounds like a reasonably easy process. Just pierce a hole into a metal blank and bend the metal down to create a continuous radial profile. What could go wrong? A lot. Splitting, incorrect dimensions, and . This table provides specific guidelines on the minimum distances required between holes, slots, and other features in sheet metal fabrication. Each parameter is carefully calculated, considering factors like material thickness .

Tapping in sheet metal is the use of a tapping tool to form material in a pre-punched or extruded thru hole, to create threads for engagement of a non-self-tapping screw. This application is typically needed for connecting one piece of sheet metal to another item. Well, you have to convince the Sheet Metal application that the extrusion is Sheet metal first, - then you can bend it. There is no difference between extrusions created in Modeling and Sheet metal, both have to be converted to Sheet Metal. . The left hole is extruded and the right is a Normal cutout, now since the hole overlaps the bend, it .Mate leads the punching industry with a tool system designed to produce threaded holes in previously punched or extruded holes, in all types of sheet metal. Called EasyTap™, this unique tool system extends the punching capabilities of today's CNC punch presses by producing precisely located threaded holes at high speed, automatically and with repeatable quality

Minimum Distance Between Extruded Holes Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal. t = Sheet metal thickness Extruded hole sheet metal,The corrugated packing of stainless steel orifice plate has an opening rate of 12.6% and an aperture of 4mm. Corrugated packing of metal 316L hole plate: it is a regular packing assembled after punching the surface of metal sheet, rolling small lines and large ripples.Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . such as louvers or extruded holes, you will need to increase the distance relative to bends and edges in order to prevent malformed features and sheet deformation . Although there has been a lack of analysis on sheet metal extrusion, the process has indeed existed and is developing quickly now. For example, the process can be used to manufacture a staged hole in the sheet metal material, or used in the combined fine-blanking and extrusion process, as shown in Figs. 2 and 3, respectively.In order to develop the sheet metal .

Sheet metal extrusion differs from ordinary extrusion, as can be seen in Fig. 1. . For example, the process can be used to manufacture a staged hole in the sheet metal material, or used in the combined fine-blanking and extrusion process, as shown in Figs. 2 and 3, respectively. In order to develop the sheet metal extrusion process, it is . Lets design sheet metal motor frame support in Creo Parametric.Insert flat pattern in the sheet metal drawing in Creo Parametric.https://youtu.be/GN8Uq_n72WU.

sheet metal rib design guidelines

Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Minimum Distance from Extruded Hole to Part Edge.DISCLAIMER:Do not us.In low carbon steel sheet metal, the minimum radius of a bend should be one- half the material thickness or 0.80 mm (0.03 inch), whichever is larger. . The minimum distance between two extruded holes is six times the material thickness. 5.Minimum Distance between Extruded Holes Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal.Extruded Holes. Forming. Heeled Punches. Keyholes. Lance and Form. Punch Louvers. Trim and Part . Sheet Metal; Coil Stock; Strip Stock; Flat Bar Stock . Other Parts. Molded Parts; Plastic Sheet & Extrusions; Composite Material; The versatile UniPunch system is capable of punching and notching many different types of parts. Send the UniPunch .

batrea lake metal boxes botw

Extrusions our commonly used to accept sheet metal screws or permit tapping into a deeper distance than just the material thickness. A pre-punched hole is required as a one hit pierce and extrude gives poor hole quality, and has limited adjustment on the machine. Whenever you modify a sheet metal design in the flat pattern, e.g. by rounding or drilling holes, all those features do not show up in the normal model view, which I would expect. I think other CAD programs do that and it .

Note that extruded holes in some material, especially stainless steel, can distort during forming. In these cases, a fabricator can apply a good forming lubricant to the material before making the extrusion. . Louver types .

basement electrical box height

sheet metal hole extrusion tool

Modifying the Extruded Hole Forming Tool. Next, you modify the extruded hole forming tool. Testing the Link to Forming Tools. Next, you test the link to the Design Library forming tool part by seeing that the change propagates to the sheet metal part. Displaying the Placement Sketch in a Flat Pattern. Next, you select the flat pattern display . Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Minimum Distance between Extruded HolesHit that like button and share. Finally, be sure to provide a knockout pin inside the die matrix (E) to help lift the extrusion from the bushing. This is especially important to prevent misfeeds in progressive dies. Another type of extrusion is the pierce extrusion. The difference between this type of extrusion and a hole extrusion: a pierce extrusion does not produce a slug.

Sheet metal extrusion is a metal forming process in which the movement of a punch penetrates a sheet metal surface and it flows through a die orifice; the extruded parts can be deflected to have .

A new tooling system produces threaded holes in all types of sheet metal, eliminating the need for secondary tapping operations or additional fasteners. . Prepunched or extruded holes on the . Want all of our free SolidWorks - Sheet Metal training videos? Visit our Learning Library, which features all of our training courses and tutorials at http:/. I have 6 holes on a bent flange, they are all put in with the extrude cut feature, and all on the same sketch. When I unsuppress the flat 2 of the holes go miss Holes Missing In Flat - DASSAULT: SOLIDWORKS 3D Design - Eng-Tips

Unattached extruded walls • The Extruded Cut tool. To access this tool, click Sheetmetal > Extruded Cut. This tool can be used to create the following features: Sheet metal cuts that remove solid material from the sheet metal wall, normal to the .

Next, you modify the extruded hole forming tool. In the Design Library, navigate to forming tools\embosses.; Right-click extruded hole and click Open.; In the FeatureManager design tree, right-click Boss-Extrude1 and click Edit Sketch.; In the graphics area, double-click the diameter dimension, 2. In the Modify dialog box, enter 8mm, and click .To Create a Sheet Metal Cut. 1. Click Sheetmetal > Extruded Cut. The Extruded Cut tab opens. The Placement tab opens by default. 2. In the Placement tab use one of the following options: When a sketch exists, click Unlink to break the association with the sketch. An internal sketch is created using a copy of the sketch.

1. An enclosure comprising: one or more planar portions of sheet metal having corresponding planes; and an array of extruded holes in a planar portion of the planar portions of sheet metal, the extruded holes: having an inner diameter; being configured as apertures for heat transfer through the enclosure; being extruded along an axis normal to a plane of the planar .

sheet metal extruded hole design

The absolute best security for your tools and precious equipment. Built to last! All .

extruded hole in sheet metal|sheet metal hole extrusion tool