anode junction box cathodic protection Resistance values of anodes on any given impressed current cathodic protection system are often different due to varying lead wire length and electrolyte conditions. Assembled with shunts and resisu0002tors, this junction box . CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

0 · junction box cathode protection

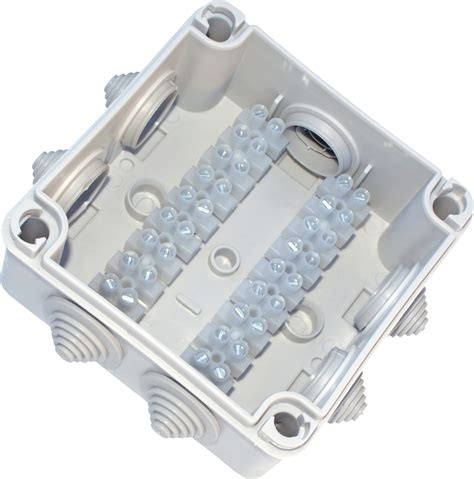

1 · junction box

2 · galvanic junction box

3 · farwest anode junction box

Tool Box Types. Let's define tool box types as the industry does, and as you'll find them defined on our website: "Tool Chest", also called a "Top Box": a multi-drawer tool cabinet, designed to work either as a stand-alone tool box, OR, sit on top of a Roller Cabinet.

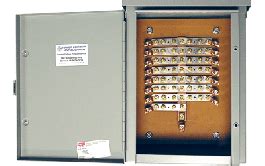

Farwest standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a Hoffman powder .Junction boxes are used to connect all the equipment in a cathodic protection systemand provide a means for easy inspection of individual anode currents. Choose fromsheet steel, stainless steel, aluminium, glass reinforced plastic . MESA Junction Boxes are designed to make electrical connections on impressed .

Farwest manufactures a wide variety of custom junction and bond boxes to meet most cathodic protection field requirements. The details and components needed for these assemblies must be provided by the end user in order for us to .

Resistance values of anodes on any given impressed current cathodic protection system are often different due to varying lead wire length and electrolyte conditions. Assembled with shunts and resisu0002tors, this junction box .Anode Engineering offers a wide range of Test Point, Junction and Bond Boxes with associated equipment for Cathodic Protection systems. The most common test point is the simple two .Our standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, .

Cathodic protection junction boxes are designed to provide a termination point anode cables, cathode (structure) cables, structure sense cable, reference electrode cables before routing to .MATCOR provides a range of cathodic protection junction boxes. We can design and manufacture junction or terminal boxes for all types of applications including explosion proof .JA Electronics provides custom bond boxes and junction boxes to connect cathodic protection system reliably and conveniently. For more information, call JA Electronics at 281-879-9903.Farwest standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a Hoffman powder coated steel enclosure, a Micarta insulating panel, copper buss bar, shunts (customer selected), and .

Junction boxes are used to connect all the equipment in a cathodic protection systemand provide a means for easy inspection of individual anode currents. Choose fromsheet steel, stainless steel, aluminium, glass reinforced plastic (GRP) and plastic, wecan provide a range of junction boxes for all types of application.

junction box cathode protection

Deep well anode box Farwest manufactures a wide variety of custom junction and bond boxes to meet most cathodic protection field requirements. The details and components needed for these assemblies must be provided by the end user in order for us to provide the desired finished product.

used electrical panel box

Resistance values of anodes on any given impressed current cathodic protection system are often different due to varying lead wire length and electrolyte conditions. Assembled with shunts and resisu0002tors, this junction box compensates the resistance .Anode Engineering offers a wide range of Test Point, Junction and Bond Boxes with associated equipment for Cathodic Protection systems. The most common test point is the simple two wire type for checking pipe to earth potential, other configurations with more connections permit testing of multiple parameters or conditions at the location .Our standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a steel enclosure, an insulating panel, copper buss bar, shunts (customer selected), and mechanical terminal lugs for cable attachment.

Cathodic protection junction boxes are designed to provide a termination point anode cables, cathode (structure) cables, structure sense cable, reference electrode cables before routing to a cathodic protection rectifiers.MATCOR provides a range of cathodic protection junction boxes. We can design and manufacture junction or terminal boxes for all types of applications including explosion proof and marine applications. Enclosures of all sizes and internal combinations have been built for worldwide CP applications.JA Electronics provides custom bond boxes and junction boxes to connect cathodic protection system reliably and conveniently. For more information, call JA Electronics at 281-879-9903.

junction box

Farwest standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a Hoffman powder coated steel enclosure, a Micarta insulating panel, copper buss bar, shunts (customer selected), and .Junction boxes are used to connect all the equipment in a cathodic protection systemand provide a means for easy inspection of individual anode currents. Choose fromsheet steel, stainless steel, aluminium, glass reinforced plastic (GRP) and plastic, wecan provide a range of junction boxes for all types of application.

Deep well anode box Farwest manufactures a wide variety of custom junction and bond boxes to meet most cathodic protection field requirements. The details and components needed for these assemblies must be provided by the end user in order for us to provide the desired finished product.

Resistance values of anodes on any given impressed current cathodic protection system are often different due to varying lead wire length and electrolyte conditions. Assembled with shunts and resisu0002tors, this junction box compensates the resistance .

Anode Engineering offers a wide range of Test Point, Junction and Bond Boxes with associated equipment for Cathodic Protection systems. The most common test point is the simple two wire type for checking pipe to earth potential, other configurations with more connections permit testing of multiple parameters or conditions at the location .Our standard anode junction boxes provide a low-cost solution to consolidate multiple impressed current anode cables and a means for monitoring individual anode currents. Build to last, these junction boxes include a steel enclosure, an insulating panel, copper buss bar, shunts (customer selected), and mechanical terminal lugs for cable attachment.

Cathodic protection junction boxes are designed to provide a termination point anode cables, cathode (structure) cables, structure sense cable, reference electrode cables before routing to a cathodic protection rectifiers.MATCOR provides a range of cathodic protection junction boxes. We can design and manufacture junction or terminal boxes for all types of applications including explosion proof and marine applications. Enclosures of all sizes and internal combinations have been built for worldwide CP applications.

galvanic junction box

used metal chicken house trusses

used cnc machine for sale near me

According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula: \footnotesize L_\text {min} \geq 8 \times t_\text {max} Lmin ≥ 8 × tmax. where:

anode junction box cathodic protection|junction box