cnc machine encoders Most CNC machines rely on encoders for feedback and positioning. There are two primary types of encoders used in CNC machines:linear and rotary encoders. These categories can be . Understanding the width, dimensions, and size of metal roofing materials is essential for selecting the right materials and calculating the cost of your project. In this article, we will explore common metal roofing measurements and how they can affect your residential, commercial, or industrial roofing project.

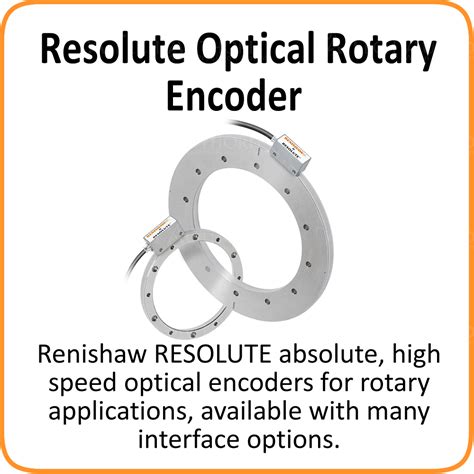

0 · renishaw rotary encoders

1 · high speed rotary encoder

2 · high resolution rotary encoder

3 · high quality rotary encoder

4 · high precision rotary encoder

5 · heidenhain rotary encoder catalog

6 · heidenhain encoder catalog

7 · cnc rotary encoder

$5.59

Encoders are essential in machine tools, providing positional feedback to the control and input on speed, accuracy and repeatability. Linear, rotary and angle encoders differ .

Encoders for CNC Machining. CNC machines must maintain position in the . Encoders for CNC Machining. CNC machines must maintain position in the face of heavy workpieces and spindles, multi-axis movement and high speeds. Encoders play a huge .Most CNC machines rely on encoders for feedback and positioning. There are two primary types of encoders used in CNC machines:linear and rotary encoders. These categories can be .

HEIDENHAIN develops and manufactures linear encoders, angle encoders, rotary encoders, digital readouts, and CNC controls for demanding positioning tasks.

Discover the vital role of position encoders in modern machining, explaining their contribution in controlling motion across linear axes, spindles, and rotary tables within high-precision CNC machines. In this application, an encoder informs the machine’s control system when to cut, ensuring accuracy and consistency. This article will review the different types of encoders, provide a basic understanding of how they .Quantum Devices manufactures high-quality, high-performance incremental optical rotary encoders suitable for a wide range of motion control applications, including CNC machining. Contact Us Buy Online. CNC machines use .

Rotary encoders from HEIDENHAIN stand for premium quality, durability, and precision, delivering accurate and dependable position and speed measurement. Due to their outstanding features and rugged, easy-to-install design, .In CNC machines, encoders are responsible for providing precise position feedback feedback to the control system. Encoders capture the movement of machine axes, such as X, Y, and Z, .

Encoders are essential in machine tools, providing positional feedback to the control and input on speed, accuracy and repeatability. Linear, rotary and angle encoders differ according to needs like directional variety, accuracy requirements and more.

Encoders for CNC Machining. CNC machines must maintain position in the face of heavy workpieces and spindles, multi-axis movement and high speeds. Encoders play a huge role in all of the components working together to mill, drill and bore correct parts. We also develop a full line of popular control systems and touch probes used to program CNC .Most CNC machines rely on encoders for feedback and positioning. There are two primary types of encoders used in CNC machines:linear and rotary encoders. These categories can be further divided based on their encoding method,which includes incremental and absolute encoders.HEIDENHAIN develops and manufactures linear encoders, angle encoders, rotary encoders, digital readouts, and CNC controls for demanding positioning tasks.Discover the vital role of position encoders in modern machining, explaining their contribution in controlling motion across linear axes, spindles, and rotary tables within high-precision CNC machines.

In this application, an encoder informs the machine’s control system when to cut, ensuring accuracy and consistency. This article will review the different types of encoders, provide a basic understanding of how they function, and present information on key considerations and important specifications for selecting the appropriate encoder for .

renishaw rotary encoders

Quantum Devices manufactures high-quality, high-performance incremental optical rotary encoders suitable for a wide range of motion control applications, including CNC machining. Contact Us Buy Online. CNC machines use brushless direct current (BLCD) motors, which require electronic commutation.

Rotary encoders from HEIDENHAIN stand for premium quality, durability, and precision, delivering accurate and dependable position and speed measurement. Due to their outstanding features and rugged, easy-to-install design, HEIDENHAIN rotary encoders have been used throughout the world for many years.In CNC machines, encoders are responsible for providing precise position feedback feedback to the control system. Encoders capture the movement of machine axes, such as X, Y, and Z, and deliver accurate information to the CNC controller. Encoders are critical to the positioning in production of advanced electronics. CNC machines must maintain position in the face of heavy workpieces and spindles, multi-axis movement and high.

Encoders are essential in machine tools, providing positional feedback to the control and input on speed, accuracy and repeatability. Linear, rotary and angle encoders differ according to needs like directional variety, accuracy requirements and more.

Encoders for CNC Machining. CNC machines must maintain position in the face of heavy workpieces and spindles, multi-axis movement and high speeds. Encoders play a huge role in all of the components working together to mill, drill and bore correct parts. We also develop a full line of popular control systems and touch probes used to program CNC .Most CNC machines rely on encoders for feedback and positioning. There are two primary types of encoders used in CNC machines:linear and rotary encoders. These categories can be further divided based on their encoding method,which includes incremental and absolute encoders.HEIDENHAIN develops and manufactures linear encoders, angle encoders, rotary encoders, digital readouts, and CNC controls for demanding positioning tasks.Discover the vital role of position encoders in modern machining, explaining their contribution in controlling motion across linear axes, spindles, and rotary tables within high-precision CNC machines.

In this application, an encoder informs the machine’s control system when to cut, ensuring accuracy and consistency. This article will review the different types of encoders, provide a basic understanding of how they function, and present information on key considerations and important specifications for selecting the appropriate encoder for .Quantum Devices manufactures high-quality, high-performance incremental optical rotary encoders suitable for a wide range of motion control applications, including CNC machining. Contact Us Buy Online. CNC machines use brushless direct current (BLCD) motors, which require electronic commutation.Rotary encoders from HEIDENHAIN stand for premium quality, durability, and precision, delivering accurate and dependable position and speed measurement. Due to their outstanding features and rugged, easy-to-install design, HEIDENHAIN rotary encoders have been used throughout the world for many years.

In CNC machines, encoders are responsible for providing precise position feedback feedback to the control system. Encoders capture the movement of machine axes, such as X, Y, and Z, and deliver accurate information to the CNC controller.

high speed rotary encoder

The integration of wifi cameras in CNC machines allows for enhanced machine efficiency and productivity. The cameras provide a visual aid that empowers operators to detect and resolve issues promptly, reducing downtime associated with unexpected machine failures.

cnc machine encoders|cnc rotary encoder