cnc machine programming g code Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. J-B Weld products are widely recognized as among the best glues for metal-to-metal bonding. Its KwikWeld epoxy glue is also effective at sticking metal to wood, brick, masonry, ceramics, and.In this article, we will explore the factors to consider when selecting a fabric-to-metal glue, the types of glue available, how to apply the glue correctly, and even alternative ways to attach fabric to metal.

0 · g code explained with examples

1 · g code commands cheat sheet

2 · g code cnc cheat sheet

3 · g code cheat sheet

4 · complete g code list

5 · cnc turning g code list

6 · cnc mill g code list

7 · cnc g code for beginners

Choosing the right gauge of sheet metal for auto body repairs depends on several factors. Firstly, consider the panel location to determine the level of durability required. Structural requirements should also be taken into account, as certain areas may require thicker gauges for added strength.

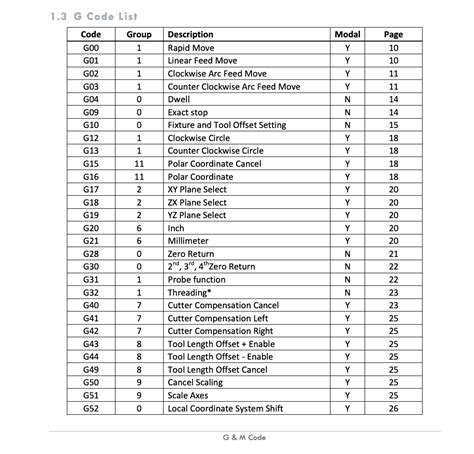

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

CNC G-codes & M Codes for milling and turning with explanations, . So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .The Four Professional G-Code training courses are a complete online training package to enable you to master CNC programming across all machine types. You will learn how to program G-Code on Milling machines, Lathes and . G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to . G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using .

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machinesCNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs?

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .The Four Professional G-Code training courses are a complete online training package to enable you to master CNC programming across all machine types. You will learn how to program G-Code on Milling machines, Lathes and machining centres. From beginner to expert in less than a week. G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow. G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

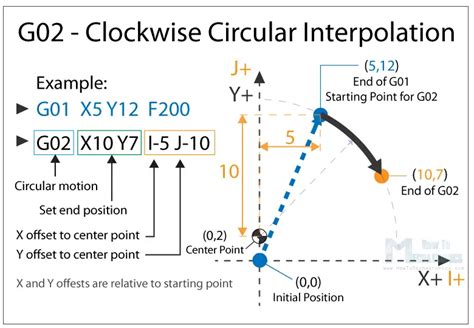

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.

I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machinesCNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs?

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .The Four Professional G-Code training courses are a complete online training package to enable you to master CNC programming across all machine types. You will learn how to program G-Code on Milling machines, Lathes and machining centres. From beginner to expert in less than a week.

g code explained with examples

g code commands cheat sheet

G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow.

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

g code cnc cheat sheet

g code cheat sheet

complete g code list

Orthodontic brackets are used as the main essence of dental braces. They are responsible for producing the required tension but the in-depth job differs for each different type of dental bracket. Some are good at .

cnc machine programming g code|cnc turning g code list