cnc horizontal milling machine axis Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Each machine has its own .

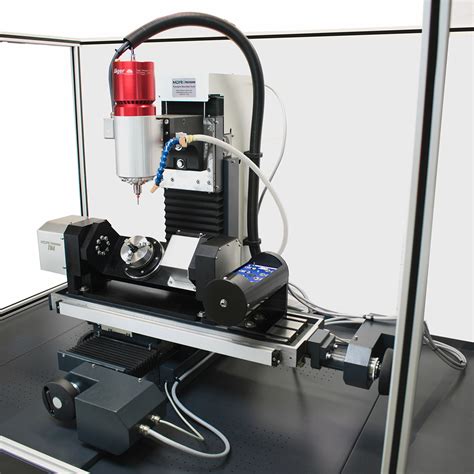

0 · small 5 axis milling machine

1 · milling machine axis diagram

2 · large 5 axis milling machines

3 · cnc machine axis locations diagram

4 · best 5 axis milling machine

5 · 5 axis vertical milling machine

6 · 5 axis milling machine price

7 · 5 axis cnc mill price

Stainless steel appliances stand out when paired with the right color cabinets because it sets the tone for a modern, sleek, and stylish kitchen aesthetic. White cabinets are versatile, market-friendly, and easy to maintain. Gray cabinets offer versatility, balance, and monochromatic appeal.

Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various . Auxiliary axes parallel to X, Y and Z are called U, V and W respectively. The quill on an HMC is an auxiliary axis parallel to the Z axis (the spindle), and hence is called W. Here’s a .The EC-1600ZT offers more Z-axis travel than the standard EC-1600. Extended Z-axis travel; Standard side-mount tool changer, 50+1 tools; 50-taper spindle with a 2-speed gearbox; Extra-large work envelope; 78" max part swing with .

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the .All Haas horizontal mills are available with 5-axis capability. Simply plug-and-play a Haas rotary to create a powerful 5-axis machine for a fraction of the price. Need help finding the right machine? Your next horizontal mill is waiting. The spindle, table, HMI (human-machine interface), controller, tool magazine, servo motor, ball screw slide, and other structural support components make up a three-axis CNC milling machine. The stock material is secured on the table.Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers from DMG MORI are extremely versatile.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better. Auxiliary axes parallel to X, Y and Z are called U, V and W respectively. The quill on an HMC is an auxiliary axis parallel to the Z axis (the spindle), and hence is called W. Here’s a detailed explanation on CNC mill axes directions, at cncphilosophy.com.The EC-1600ZT offers more Z-axis travel than the standard EC-1600. Extended Z-axis travel; Standard side-mount tool changer, 50+1 tools; 50-taper spindle with a 2-speed gearbox; Extra-large work envelope; 78" max part swing with integrated 4th axis (optional)In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

Horizontal machining center with highest stability, precision and dynamics. Max. X-axis travel. Max. Y-axis travel. Max. Z-axis travel. Up to 2,362.2 ipm feed drive and up to 1.2 g acceleration. Thick, high-rigidity bed. High rigidity bed due to stepped X-axis guideways. Automation is a key element of digital production.Horizontal Mills designed for maximum efficiency. These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations.The world’s fastest rotary axis drive system, which achieves zero backlash. High-speed rotation and high-precision indexing; Less maintenance and longer product life; Space-saving design. Machine height 106.7 in. Machine width×Machine depth 94.4×157.6 in.

All Haas horizontal mills are available with 5-axis capability. Simply plug-and-play a Haas rotary to create a powerful 5-axis machine for a fraction of the price. Need help finding the right machine? Your next horizontal mill is waiting.

small 5 axis milling machine

The spindle, table, HMI (human-machine interface), controller, tool magazine, servo motor, ball screw slide, and other structural support components make up a three-axis CNC milling machine. The stock material is secured on the table.Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers from DMG MORI are extremely versatile. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

Auxiliary axes parallel to X, Y and Z are called U, V and W respectively. The quill on an HMC is an auxiliary axis parallel to the Z axis (the spindle), and hence is called W. Here’s a detailed explanation on CNC mill axes directions, at cncphilosophy.com.The EC-1600ZT offers more Z-axis travel than the standard EC-1600. Extended Z-axis travel; Standard side-mount tool changer, 50+1 tools; 50-taper spindle with a 2-speed gearbox; Extra-large work envelope; 78" max part swing with integrated 4th axis (optional)In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.Horizontal machining center with highest stability, precision and dynamics. Max. X-axis travel. Max. Y-axis travel. Max. Z-axis travel. Up to 2,362.2 ipm feed drive and up to 1.2 g acceleration. Thick, high-rigidity bed. High rigidity bed due to stepped X-axis guideways. Automation is a key element of digital production.

Horizontal Mills designed for maximum efficiency. These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations.

milling machine axis diagram

large 5 axis milling machines

cnc machine axis locations diagram

The best metal roof color for a red brick house is dark bronze or charcoal gray. This will create an attractive contrast with the red brick and help the roof blend in more with the surrounding environment.

cnc horizontal milling machine axis|small 5 axis milling machine