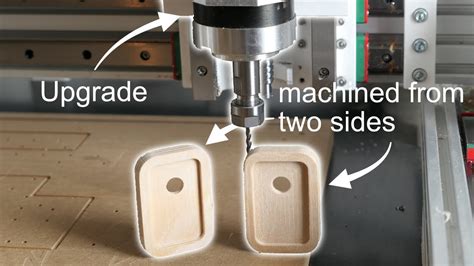

how to mill both sides of a part cnc router Wall Pocket Hook Files: https://www.cncwithme.com/---ALTMILL CNC: https://sienci.com/product/altmill/?ref=odjjyzvgControl Panel Computer: https://sienci.com/. Calculate patterns in seconds and get higher quality results. Performs operations and conversions with the English and decimal system. Shop Tools !!! Pen for marking on metal with double and retractable tip. Since 2011 FLAT METAL .

0 · Two Sided Machining

1 · Two

2 · Technical Tip of the Week: How to Use a Compression Bit

3 · Mastering CNC Two

4 · Machining both sides of a part?

5 · Look at CNC from Both Sides Now

6 · How to Easily and Accurately CNC Engrave on Both Sides

7 · Full Altmill Cut Process With gControl

8 · Demonstration Videos

9 · CNC router projects involving two

We’d Love to Hear From You, Get In Touch With Us! Please complete the form outlined below. Include in the Message box any details you think are pertinent. Someone from our office will .

cut softjaws with the profile of the first machined side of your part. part will perfectly nest when flipped, provided you do it right. Cut a "god hole" or other feature in your hard jaw .Wall Pocket Hook Files: https://www.cncwithme.com/---ALTMILL CNC: https://sienci.com/product/altmill/?ref=odjjyzvgControl Panel Computer: https://sienci.com/. In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid.

stainless steel bbq cabinets canada

Go to your CNC router, place the stock you want to engrave and secure it to the cutting bed. Drill the locating holes and engrave your design on one side. I used an 1/8 end mill for drilling - it's .This collection of videos illustrate my techniques for milling or machining parts on my CNC router that involve CAM operations on two (2) sides.One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of . In this video Ryan shows you how to machine both sides of your project on the WorkBee CNC Machine - if you've got any questions then feel free to ask in the .

This video demonstrates how to use an alignment pin technique to mill from both sides to create a full 3D project. View Video. Carving VS Machining. While most CNC systems and software will .

CNC routers need bits. They determine the kind of processing you can do, the resolution of your finished designs, and how fast you can move through the material. A . drill a hole in the top left corner. Make your toolpath's group for that side home to the top left. (0,0,0) on side 2 make home the bottom right. Use the same hole when homing .Building A CNC Mill | How To Make A CNC Router | Building Your Own CNC Milling Machine | Building CNC Mill | How To Build A CNC Router From The Scratch . CNC routers are an essential part of any machine shop, but .

Unless you have access to a mill or precision plotting and hole drilling already, it's fairly difficult to make your own frame parts that are both rigid and precise. Don't get me wrong, it's entirely possible to create a CNC frame leveraging 3D printing for some precision, but the low rigidity and damping of thermoplastic means machining . 1, Preliminary preparation Adequate preparation before milling both sides of the part is crucial to ensure machining quality and efficiency. Firstly, it is necessary to carefully check the various functions of the CNC router, including spindle rotation, feed system, cooling system, etc., to ensure that the equipment is in good working condition.This video demonstrates how to use an alignment pin technique to mill from both sides to create a full 3D project. . Carving VS Machining. While most CNC systems and software will model and carve most parts, Legacy will teach you how to use cutter profiles and tool paths to produce a better part up to 10 times faster. . 3 axis CNC router . Hopefully, you can improve your CNC machine accuracy (or your 3D printer) by eyeing the items mentioned here. Other articles you may be interested in: Stepover in CNC CAM; The best CNC software (including CNC control software) The best CNC routers; The best metal CNC machines for aluminum; The best sites for DXF CNC files; Best CAD-CAM software

There you have it, those are the best double sided tapes for your CNC Router. Any of these 3 tapes will work with most applications you will need for your CNC Router projects. However, after an in-depth review, the best double sided tape for CNC routers we recommend is the XFasten Double Sided Woodworking Tape.

For tooling start-up costs I expect to spend maybe 0 tops Forget that number. You need a bare minimum of a vice (0), 7 tool holders (00, you forgot a drill for that tap, ER32 for application flexibility), collets (0), a pack of each of your cutters (since you will inevitably ruin a bunch learning - your 0), part stops, and so on. . Figure 00 to make a single type of . I have a CNC mill and I'd like to mill both sides of a object Does anyone have any pointers, tips, tricks on how I can align the part correctly after flipping it over? Similar Threads: machining both sides of a part in SprutCAM; Need Help!-machining multiple sides of a part; All sides one Part file; Machining both sides of a part? 4 axis CNC router generally can be divided 4th axis CNC router and rotary axis CNC router. Compared to the 3 axis CNC router, the 4th axis engraving machine is special in its spindle which can swing 180 degrees left and right. And this type 4 axis CNC router not only can realize plane processing but also make work possible on both sides.

On the flip side, 6040 CNC routers like the 00 ones from China will have a bed size closer to 20"x14". . We don't often make large parts, but we do a lot of parts which have a 2D profile of say 10" square. We wouldn't be able to cut this on most CNC mills, it looks like. . Check out the Symbiosis router/mill from Stoney CNC. I wanted a .

How to set up your CNC router. When processing small parts there will inevitably be very little vacuum hold. This may particularly be a problem at the end of the cut cycle as the part is likely to move. . This will invariably drag the part towards the tool, damaging both in the process. If the material is thick (10mm or above) then this will . The secret of the impossible dovetail is they are at an angle. So make multiple tool paths. Cut the widest part of the female dovetail with a flat end mill to remove the majority of the waste. Then make the dovetail cut at full depth with a .

Both machines are potentially highly profitable if you use your imagination and keep them running regularly. Took me about three years to generate enough revenue to pay off the CNC router, but the laser paid for itself in the first year I owned it. Both were fantastic investments that I wished I had committed to getting way earlier. I'm cutting parts that have pockets on one side and engravings on the other. I have bolts in my CNC table that I use to secure my wood. The wood has pre-drilled holes. So, the wood piece sets down over the bolts and is . 💎SpeTool Bits https://spetools.com/?ref=SALE ADD coupon code "𝐒𝐀𝐋𝐄" at checkout to get an extra 12% discount on your order!How To Fi. CNC routers need bits. They determine the kind of processing you can do, the resolution of your finished designs, and how fast you can move through the material. . Where both sides of the material require the best .

3- If the sides of the part aren't square to the bottom when you clamp them in the vise, then that too can pull the part out of "square" when you clamp. On parts that are thin like that, you need to stand them up in the vise, and/or clamped against a good angle plate, and trim the thin edges that will get clamped between the vise jaws.CNC machining has revolutionized the manufacturing industry, offering precise and efficient methods for creating complex parts. One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece.(CNC Forum) From contributor T: One approach would be to manually nest as many as you can get in your built up stock material. Then, cut along both sides of the parts, but do not cut them loose. If they are very thin, once you cut them loose, they will take off on you. You can then remove them from the CNC and manually cut them loose.Just finished the cnc router pictured above (picture was a couple of days ago) anyway, got it up and running, or so I thought, then when doing the settings of the two motors on the X axis, I quickly realised something wasn't right, if standing at the front of the machine, the X axis moves faster as its going away from me at the right hand side .

stainless steel 4 drawer cabinet

Hi, in the following two videos I documented the build of my DIY CNC machine. It's a 3-axis router with a wooden frame. Part 1 of the video shows the build of the frame while part 2 shows in detail how all the electronic components are connected. This video outlines a standard workflow for setting up a double sided 3D model toolpath in Vectric software for your i2R CNC.Check out how our 3D Cut turned . This technology is essential for manufacturers aiming to maximize the capabilities of their CNC routers and sustain high productivity levels. 7. Integration with CAM Software. Integration with CAM software greatly simplifies locating Part Zero on CNC routers. It streamlines setup for machining operations. Ensure that the router will not run into the clamps. You can make sure by moving your router to the outer dimensions of the part you are making. Securing the material on one side can sometimes cause the material to lift up on the opposite side. Double check that the bottom of the material is flat before milling

When checking the plumbness of the router you want to put a square on the bed and look down the direction of the Y axis. You won't actually put the square on the router, rather you will have the square a few inches in front, close one eye, and see if the body of the router in the background lines up. Do the same in the X direction. - Save part, close bobcad, then reopen the part. (This is to work around the possible crash of editing your stock) - Right click on machine setup 2, edit - Select origin for side 2, and change the work offset if needed - Tool path your part for side 1 under machine setup 1 - Tool path side 2 - Run simulation, you will see the part flip for side 2.

Two Sided Machining

stainless steel bathroom cabinet suppliers

Two

Technical Tip of the Week: How to Use a Compression Bit

$59.95

how to mill both sides of a part cnc router|Full Altmill Cut Process With gControl