technic metal fabrication & Technic has extensive experience with all piping for the metal finishing industry, offering expertise in PVC, CPVC, ABS, PVDF, black iron, . See more The ZAG range has many features which lend itself to a whole host of applications including junction boxes, both industrial and hazardous area, .

0 · what are fabricated metal products

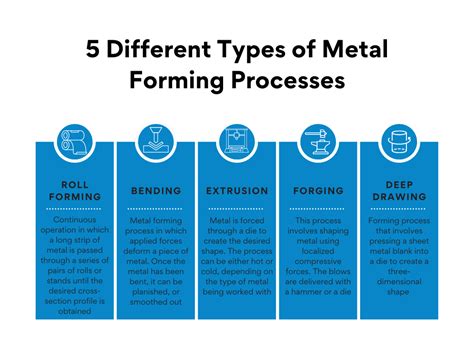

1 · types of steel fabrication

2 · types of metal processing

3 · types of metal fabrication processes

4 · manufacturing processes for metals

5 · manufacturing methods for metals

6 · manufacture of fabricated metal products

7 · basic metal fabrication

Main products Baby Bottle Warmer, Baby Bottle Sterilizer and 989 more Products from Zhongshan Yoice Electric Appliance Co., Ltd. on Alibaba.com

Our fully equipped plastic fabrication shops enable us to produce thermo plastic products such as tanks, rigid tank liners, ventilation exhaust hoods and duct of virtually any size and shape. PVC, CPVC, polypropylene, PVDF and acrylic. Our equipment includes Wegener formers and fusion butt welders. See moreTechnic fabricates all of its metal structures in-house. Our welders are AWS Certified Welding Fabricators and have capabilities with mig, tig, stick, plasma cutting and pipe welding. They regularly fabricate with structural steel, stainless steel, titanium, light . See moreTechnic has extensive experience with all piping for the metal finishing industry, offering expertise in PVC, CPVC, ABS, PVDF, black iron, . See moreTechnic fabricates custom designed control and operator consoles, layout of conduit and line wiring of complete wet process systems. Our electrical shop services, repairs and calibrates electrical products such as rectifiers, timers and amp meters. All . See more

In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make .

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .What are the different types of metal fabrication? Cutting; Metal stamping; Welding; Extrusion; Forging; Casting . Before a raw metal material can be used for manufacture and assembly, it . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .

Metal fabrication is easy to understand at an elementary level. With that being said, the numerous metal fabrication processes involved are each unique and highly detailed. Knowing the basic tenets of each is key to .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on .Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves . Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is .Precious Metals for Advanced Semiconductor Applications. Technic originated as a supplier of precious metals to the jewelry industry in the 1940’s. In the 1950’s Technic expanded their precious metal expertise to the electronics industry. Today Technic is one of the leading suppliers of precious metal specialty chemistry to the electronics industry.

Metal fabrication is the process of shaping and manipulating metal into desired structures or components. It involves various techniques such as cutting, bending, and assembling, which transform raw materials into finished products. Metal .5/222 Headland Rd, North Curl Curl New South Wales 2099, AustraliaTechnic manufactures polypropylene tanks as part of automated systems, manual tank lines or individual tanks. All tanks are constructed from natural, stress relieved polypropylene material. Tank fabrication includes butt welding or fold/weld methods to enhance tank strength and reduce the potential for leaks. Metal fabrication is a broad term referring to any process that cuts, shapes, or molds metal materials into a final product. Instead of an end product being assembled from ready-made components, fabrication entails creating an end product from raw or semi-finished materials.

Technic's advanced PCB fabrication and packaging chemistries are engineered to reduce environmental footprints through on site reclaim of metals, as well as the use of concentrates, lead free final finishes and biodegradable products. Due to the cost efficiency of concentrate usage, increased production capacity, and reduced raw material usage .

what are fabricated metal products

types of steel fabrication

Forming Techniques. Forming techniques involve reshaping metal into desired forms without adding or removing material. Common methods include: Bending: Performed using press brakes, where metal sheets are bent to create angles and shapes. Rolling: This method uses rolling machines to curve or roll metal into cylindrical shapes. Stamping: Involves pressing metal into .

Metal fabrication techniques are vital in industries like manufacturing, construction, etc. There are various techniques like forging, casting, machining, etc. Such fabrication techniques allow the creation of custom parts and components essential for successful projects. Understanding the techniques is crucial for achieving precise and high .

Key Takeaways Metal fabrication is a complex and varied process that involves numerous techniques, from welding to cutting. It is crucial in the automotive, aerospace, and construction industries. Understanding its applications can aid in selecting the appropriate method for specific industrial needs. Metal fabrication blends craftsmanship and technology, employing .

Welcome to Laser Technic®, Noida, your one-stop destination for high-quality custom sheet metal fabricated parts and assemblies. We manufacture panel enclosures, electronic enclosures, cabinets, battery boxes, kiosks, telecom tower/antenna clamps, and industrial & IT racks. Besides metal fabrication, we also offer metal laser cutting and CNC bending services. Our team of .

Metal finishing is an essential process in the metal fabrication industry, ensuring high-quality end-products through various techniques. One such method is powder metallurgy, which produces items from powders via three main steps: blending & mixing, compaction & sintering, and secondary operations including sizing/finishing. Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, . When you’re aiming for high-quality metal parts fabrication, it’s vital to take into account techniques that guarantee precision and durability. Methods like laser and water jet cutting offer intricate designs with minimal waste, while advanced welding techniques, such as laser welding, provide robust joints with reduced distortion. Effective metal forming processes . The Importance of Understanding Sheet Metal Fabrication Techniques. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.

In addition to machining and sheet metal fabrications, our technical team has in-depth knowledge of metallurgy and a wide range of metal forming processes to assist our customers in selecting cost effective processes and materials. . Ready to tackle your next metalworking project? In this video, we reveal essential techniques for DIY metal cutting, whether you're working with sheet metal,.

Sheet Metal Fabrication Techniques 8. Thread starter Dinga17; Start date Sep 22, 2018; Status Not open for further replies. Sep 22, 2018 #1 Dinga17 Mechanical. Sep 22, 2018 15 AU. Hi all, I am attempting to make a non-truncated cone with a very shallow taper/slant angle. My knowledge of fabrication methods and processes is not up to par and . Sheet Metal Fabrication: Techniques and Tips for Beginners and Pros covers the necessary tools and how to use them; how to choose, prepare, and work with the most suitable material; how to make bucks, plugs, and mock-ups; and how to cut, bend, form, and join sheet metal. Whether you want to shape a fender for a custom car, re-create damaged . Standard Techniques in Metal Fabrication. Two crucial methods are laser cutting and welding in metal fabrication. High-precision laser cutting creates complex designs without sacrificing material integrity by means of concentrated laser beams. This environmentally friendly, low waste generating energy-efficient approach is Conversely, welding .

Metal Fabrication Techniques. Metal fabrication encompasses a range of essential processes, with cutting metal standing as a fundamental step for achieving precision and intricate shapes. Within this realm, techniques like laser cutting are indispensable. However, metal fabrication extends beyond cutting and includes a variety of crucial .2,989 Followers, 80 Following, 271 Posts - Laser Technic® (@lasertechnic.in) on Instagram: " India Bringing Sheet Metal To Life!® Metal Fabrication | Laser Cutting | CNC Bending | 3D Modeling ☎️+91 9891022223 [email protected]" 1.0 THEORY The term ‘sheet metal’ is used to mean metal having thickness in the range from 0.4mm to 6 mm. When the thickness is more than 6 mm, the metal is called a plate. Products made from sheet metal can be found almost anywhere. Metal tables, steel cabinets, car bodies, beverages cans and home appliances are some of the common examples. The .

Specialty Chemicals, Technical Expertise, Innovation & Service. For more than 75 years, Technic has been a global supplier of specialty chemicals, custom finishing equipment, engineered powders, and analytical control systems to the semiconductor, electronic component, printed circuit board, industrial finishing, and decorative industries.© Deepak and Technic Private Limited. Follow; Follow; Follow; Follow

Sheet Metal Fabrication Techniques. Sheet metal fabrication technology encompasses a wide range of cold processing techniques for sheet metal.. As the use of sheet metal components continues to grow, sheet metal processing technology has become an integral part of product development. Designers must have a good understanding of the properties of .

Advanced Bending Techniques in Sheet Metal Fabrication CNC Press Brake Operation. At the heart of modern bending technology lies the CNC press brake operation. This cornerstone of precision fabrication offers unmatched accuracy and repeatability, revolutionizing how metal is shaped. Computer-controlled to execute detailed bending instructions .Technic Inc. provides parts, supplies, . Each location offers engineering, fabrication, assembly and service departments. Learn more. Amp Hour Meters, Timers & Chemical Feeders . Technic's precious metal recovery equipment is designed for reliability and conveyance of operation and maintenance.

types of metal processing

types of metal fabrication processes

When fabricating sheet metal parts, using a bead roller can add strength to the panels and return new parts to a factory look. Join Mark Simpson in this introduction to bead rolling as he demonstrates how to use a bead roller to roll flanges and beads.

technic metal fabrication &|types of steel fabrication