basics of metal fabrication The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . With 115 colours, our Professional Watercolour range offers bright, vibrant colours and unrivalled performance. Watercolour, more than any other medium, reflects the unique characteristics of the pigments used and our Professional Watercolours use only the finest pigments, and are known for their brilliance, permanence and strength of colour.

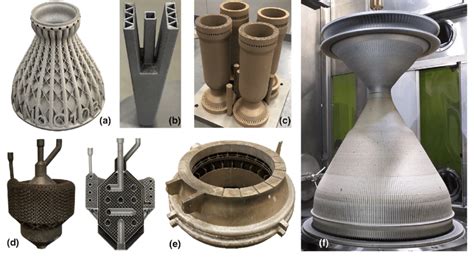

0 · your examples of fabricated parts

1 · what are fabricated metal products

2 · sheet metal assembly techniques

3 · manufacturing processes for metals

4 · manufacturing methods for metals

5 · manufacture of fabricated metal products

6 · different types of metal fabrication

7 · basic metal fabrication

Check out this video where we walk you through how to install an electrical junction box step by step. Subscribe to The Spruce for beginner-friendly how-tos, real-life .

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost . This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right . Understanding Metal Fabrication. Metal fabrication is the process of shaping, cutting, and assembling metals to create various structures, parts, and products. It .

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is . Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Sheet metal fabrication involves fabricating parts, components, and assemblies from metal sheets. It encompasses many operations, such as shearing, blanking, bending, welding, riveting, mold forming, and surface treatment. Unlock the full potential of sheet metal fabrication with our comprehensive guide! Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project.

Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right fabrication shop for .

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Understanding Metal Fabrication. Metal fabrication is the process of shaping, cutting, and assembling metals to create various structures, parts, and products. It encompasses a broad spectrum of techniques, from cutting and welding to forming and finishing, each tailored to achieve specific results.

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success. Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Sheet metal fabrication involves fabricating parts, components, and assemblies from metal sheets. It encompasses many operations, such as shearing, blanking, bending, welding, riveting, mold forming, and surface treatment. Unlock the full potential of sheet metal fabrication with our comprehensive guide! Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project.

Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.

This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right fabrication shop for . Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Understanding Metal Fabrication. Metal fabrication is the process of shaping, cutting, and assembling metals to create various structures, parts, and products. It encompasses a broad spectrum of techniques, from cutting and welding to forming and finishing, each tailored to achieve specific results.

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success. Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Sheet metal fabrication involves fabricating parts, components, and assemblies from metal sheets. It encompasses many operations, such as shearing, blanking, bending, welding, riveting, mold forming, and surface treatment.

cube3 metal expansion enclosure

your examples of fabricated parts

what are fabricated metal products

sheet metal assembly techniques

I am trying to solve a problem in conforming to code for electrical outlets and kitchen counters. I have a 15′ window behind a kitchen counter, sink in the middle, and no backsplash. The window sill will be about an inch above the counter top. Forum members have suggested Mockett’s PCS34 but I’m hoping for another solution.

basics of metal fabrication|your examples of fabricated parts