sizing process in sheet metal Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: . $197.30

0 · what is sheet metal size

1 · thin sheet metal size

2 · standard sheet metal dimensions

3 · sheet metal thickness chart

4 · sheet metal forming dimensions

5 · sheet metal distance calculator

6 · sheet metal diameter chart pdf

7 · how thick is sheet metal

Sell your Cnc Machined Parts products to global buyers for Free. There are currently 985 Cnc Machined Parts international importers waiting to connect with suppliers on Tradewheel.com.

Generally, dimensioning should be done from a feature to an edge. Avoid feature-to-feature dimensions over two or more planes. Feature-to-bend dimensions may require special fixtures . All About Sheet Metal – Materials, Standard Sizes & Forming Processes. Sheet metal is the basis of all engineering today. We can see it everywhere – from cars and .Sizing is a metal forging process that is used mainly to finish work that has already been manufactured. It is a cold forming process. Metal sizing uses a lot of force over a short .Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including . The sheet metal fabrication process consists of two main processes; forming and cutting. These two techniques work together to create the final form of any product. While cutting is a simple process, forming has further .

what is sheet metal size

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. . 5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are .

A full sheet of sheet metal can vary in size, but a common standard size is 4 feet by 8 feet (48 inches by 96 inches). What is sheet metal drawing ratio? The sheet metal drawing ratio is the ratio of the initial blank diameter to .

The Advantages Of Precision Sheet Metal Fabrication Process. The precision sheet metal fabrication process is ideal for high-quality manufacturing due to the various benefits it offers. For example: Customization: This process allows manufacturers to produce parts and components tailored to meet precise requirements. They just need to modify . Sheet metal screw sizing is critical for spot welds. Learn how to select the right screw size for your spot welding applications and ensure strong, secure joints in sheet metal. . Spot welding is a highly efficient and cost-effective method for creating hat channels, as it is a simple, automated process that requires minimal setup. It is also .It is a crucial procedure in sheet metal manufacturing as it allows for the shaping and sizing of the metal to specific dimensions. . The deburring process in sheet metal processing is vital to ensure safety and the overall finish of the final product. This step involves removing any sharp edges or “burrs” left from the previous processes . Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It involves removing excess material from a workpiece, bringing it to its desired size and shape. However, there are various trimming operations, each with its unique characteristics and applications.

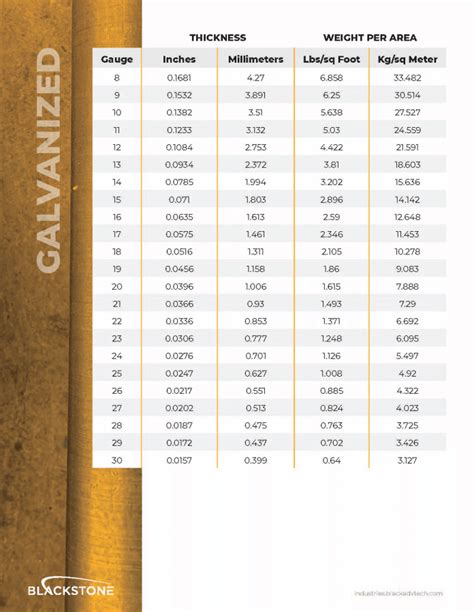

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. Like any manufacturing process, sheet metal hydroforming has its advantages and limitations. One of the biggest advantages is its ability to produce complex parts with tight tolerances and smooth surfaces. . One limitation is the size of the parts that can be hydroformed, as the process may not be suitable for very large or heavy parts. The . Spinning speed various with size, design, type of metal and thickness of sheet metal. Aluminum copper, bras and stainless steel can also be spun in spinning process. This process is mainly suitable for producing conical shape parts and suitable for low volume production. Components produced in this process do not require any trimming or beading .

In the world of sheet metal manufacturing, precision, and quality are paramount. Among the various processes that contribute to these factors, trimming holds a significant place. Trimming, essentially a shearing process involves cutting off excess material from the sheet metal part after it has been formed. Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. . Selecting the correct thickness is a critical part of the sheet metal fabrication design process. That’s why we’ve created this handy guide. The process is relatively inexpensive in large quantities and capable of punching a hole in strip as well as sheet metal. Holes of varying sizes can be punched but it is usually recommended that the diameter of the hole required is greater than the thickness of the material being punched. . In this process, the sheet metal is passed through a .

Cold sizing, like all other cold forming processes, has a hot process counterpart. In addition to semi-finished parts, cold forming may be used on metal stock, sheet, bar, and rod stock. Cold sizing can be performed on various metals, both ferrous and non-ferrous, and even materials like polymers and plastics.

the forming process, and the fact that dimensional variation is introduced at each bend, . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Minimum hole sizes are related to stock thicknesses and can be as low as 20% of the stock thickness. Turret Press Basics

In this article we will discuss about the sheet metal manufacturing process and its operation types. Introduction to Sheet Metal Work: Most of the sheet metal work is done on presses where a die and punch or other formed tools are required. In press work large force is applied on thin sheet metals to give the required shape or to cut it in to the desired shape. Press work is highly . Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. . The metal sheets are formed and cut into the .Small hole size in sheet metal requires smaller size punching tool which may leads to break during the operation. It is recommended that the diameter of the hole should be equal or more than the thickness of the sheet metal. . Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. .

Fig. 2 Radial riveting equipment and riveting process. Process selection and precautions of riveting (1) The size of the riveting bottom hole should be designed in strict accordance with the manuals of general or special equipment, standard parts, and should comprehensively consider the material, thickness, model, and strength requirements of the . The versatility of sheet metal allows these enclosures to be customized extensively in terms of size, shape, features, and finishes, making them indispensable in applications ranging from industrial machinery to consumer electronics. . CNC (Computer Numerical Control) punching is a process where sheet metal is fed into a press that houses .

thin sheet metal size

Guide to Sheet Metal Forming Process, Standard Sizes and Materials, Creatingway offers various fabrication and 2nd process services your projects. Skip to content +86-0(755)-89492523 UTC +8 : 8:00-22:00. Request a Quote; top menu. [email protected].

Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production.Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and KnightPunching is a prominent process in sheet metal fabrication that involves the use of a punch and die to create holes, slots, or other geometric features in sheet metal. This versatile technique is widely employed in the production of sheet metal components across diverse industries, including automotive, electronics, and construction.

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal is fed into a press, where the stamping tool, also known as a die, creates the desired shape.The die is pressed into or through the metal with tremendous force. Notches are the inward cut from the edge of sheet metal with a measured angle suitable for a particular application. . Why are tabs and notches essential in the sheet metal fabrication process? Tab and notch features are beneficial in manipulating sheet meals in desired shape and size. It makes assembly, handling, and inventorying easier. .

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

dark brown outdoor electrical box

standard sheet metal dimensions

USA Dutch – your complete source for precision sheet metal fabrication, from laser cutting to punching, bending, welding, assembly, and even CNC machining.

sizing process in sheet metal|standard sheet metal dimensions