how to attach two pieces of sheet metal together Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. It involves connecting or attaching multiple sheets of metal together to create a desired shape or form. Hi, in this instructable I will go over how to create a 2-Axis CNC machine. This particular design utilizes parts which can be purchased at local hardware stores, reducing the price greatly. It also uses 3d printed parts which allow for customization and reduces the price even more.

0 · sheet metal joining technology

1 · sheet metal joining techniques

2 · sheet metal joining screws

3 · sheet metal joining process

4 · sheet metal connection process

5 · joining two pieces of metal

6 · joining sheet metal without welder

7 · how to join sheet metal

Twisted Metal Fabrication located at 185 Grand Ave, Fallon, NV 89406 - reviews, ratings, hours, phone number, directions, and more.

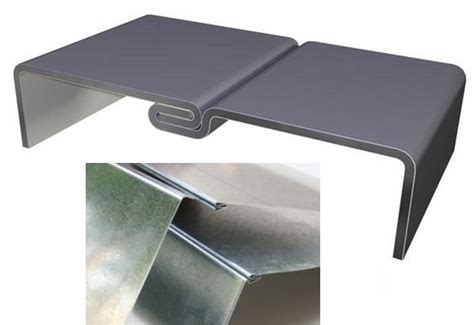

Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. It involves connecting or attaching multiple sheets of metal together to create a desired shape or form.

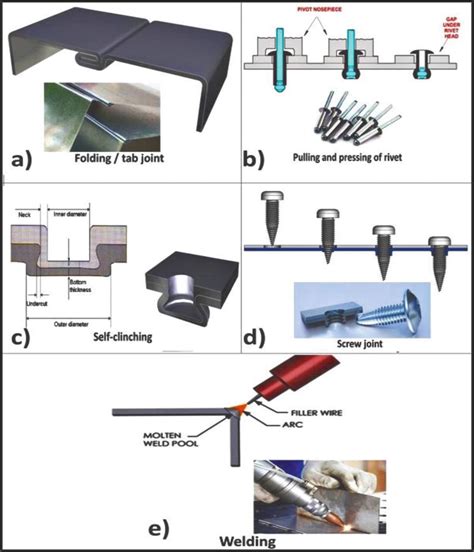

How can we ensure secure and durable connections in sheet metal fabrication? . No welding equipment? No problem! Today we show the #verycoolgang 3 different ways to attach two pieces of metal without using a welder!It is possible to join metal pieces by methods like riveting, soldering, bolting or brazing. Other than this, nano metals and adhesives can also be used to join metal pieces together without welding. Clamp the pieces together. Remove any glue that squeezes out. You can try using construction adhesive meant for non porous surfaces. This is hard to squeeze flat for a short .

Standoffs can be used to attach two parts in multiple ways. The simplest method is acting like a regular standoff with threads to stack two parts on top of each other. The other .1. Welding can be used to fuse two pieces of sheet metal together, typically forming a permanent join through the application of heat. When completed correctly, welding provides an extremely strong bond between the parts and, .

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You’ll discover the pros and . 1. Assembling Sheet Metal With Fasteners i.e. Nuts & Screws. You can use fasteners such as nuts and screws to directly hold onto sheet metal pieces. These fasteners will ensure a perfect fit. You can also disassemble .

Open the cap and use a brush or spatula to apply the glue on both surfaces. Epoxy metal glue might require some mixing while superglue might only require you to put a single drop on each square inch. Joining the metal pieces. .

Place the two pieces of aluminum together on the drill press, aligning them, so they are even; this will ensure that the holes line up perfectly when drilling. Using a countersink bit, carefully drill through both pieces of . Sanding the metal roughs up the surface, which helps the glue stick. Use 150- to 220-grit sandpaper or a sanding block on both pieces of metal in the spots to be glued. Make sure the metal is thoroughly cleaned first, since . I want to connect two sheet metal faces with a bend.Bend works if two parallel edges are selected.Is there a way to connect two faces with a bend if the two edges are not parallel? Thank you. . Attach your file here.----- Autodesk Inventor 2019 Certified Professional Autodesk AutoCAD 2013 Certified Professional .

which of the following methods is commonly used to fabricate custom hanging arrangements for air handlers and similar pieces of equipment . there are 18 threads per inch on this machine screw. set screws are typically used to. join two sections of sheet metal together. cone and oval points are most likely found on set screws with which types . Are you looking to switch away from welding?You’re struggling to find highly skilled welders or you are experiencing issues with welded joints?Here at Forgew. You can now proceed to join the two parts together, ensuring you don’t leave any gaps in-between. Leave them out for some time for the boding to form. You can clamp the two parts together to give the aluminum proxy ample time to cure and form a lasting bond. . Once you have the metal pieces in position, you let the filler metal flow through .Heat. That's the best and permanent way. I would find a piece of metal that you can heat, like a pizza cutter. Heat it with a torch and then run it on top of the two sheets where you want to join them. I have a bag sealer that works on that principle (heat) It will take some practice to get it right so you don't burn the plastic through.

Often, you need large metal fabrications that are not practical to make in one piece, and examples can be a machine frame, a machine base, etc. In such cases, splitting the total fabrication into two or more small fabrications and then assembling them together using nuts, bolts, and washers (fasteners) can be advantageous. The reason being where the metal gets caught on the mating piece, when you push down to tuck it in so to speak, the other piece will try to follow it down too. The free fingers will help govern this problem, but the thumbs do most of the pushing in to get the parts to line up.HOW to seperate two pieces of sheet metal binded together with spot welds. Good Afternoon, . (looks like there is seam sealer that seals the panels together) Then use a grinding wheel on a dremel to remove the spot welds (carefully without ruining the panel behind it) . comments sorted by Best Top New Controversial Q&A Add a Comment. More . How strong are J.B. Weld’s adhesive capabilities? I decided to do a simple test to see if J.B. Weld could adhere two pieces of steel together and see how wel.

Rivets provide a low-cost, simple installation process that can be easily automated. Use them to join thin sections of plastics, plastic to sheet metal or plastics to fabric. To minimize stresses, use rivets with large heads — three times the shank diameter is suggested — and washers under the flared end. Never use countersunk rivets. How to use a rivet gun. in this video I show you how to join two pieces of metal together using a rivet gun. it is easy to do and very cost effective if you .

This can be a lower cost option in terms of setup. It’s a solid way of joining pipes together, too. For brazing, you use a flame torch to heat up the two pieces of metal with a flux to protect it from corroding. Then you use a braze (a . This Mig Welding Video Demo shows how simple and easy it is to use a MIG welding machine. Mig Welding Machines are use throughout the world. They are the suited for many welding applications. This video demonstration .You don’t need welding tools to attach two pieces of metal. For ordinary household repairs and DIY projects, you can use super glue to get the job done in no time at all. . Simply squeeze out a small amount of glue to one of the metal surfaces, then press the two surfaces together for about 30 seconds. Afterwards, leave the object to dry . This video shows how to solder two pieces of flat copper together. I used a propane torch, Nokorode Pre-tinning paste flux, and Solder Safe lead free solder .

The first step when joining stainless steel sheets is cleaning the surfaces of both pieces. This is crucial because any dirt or debris left on either piece could prevent them from adhering properly. To clean them, use a degreasing agent like lacquer thinner or acetone and wipe off any grime with lint-free cloths. Step 2: Prepare Your Joints

sheet metal joining technology

I’m a beginner mig welder trying to learn how to join together two pieces of sheet metal like that on a car that I’m planning on welding in the future. I have two questions and a one problem. My questions are what kind of gap should be between the two pieces of metal the size of the gap I have between the metal I have been practicing with .A subreddit dedicated to the ancient art of blacksmithing. Show off your latest creations or get advice on a problem. This subreddit is temporarily private as part of a joint protest to Reddit's recent API changes, which breaks third-party apps and moderation tools, effectively forcing users to use the official Reddit app.

Super Alloy 1 contains cadmium. Super Alloy 1 can easily solder galvanized steel plates together. Super Alloy 1 has a very low melting point which prevents t. The best way to join two pieces of metal without welding is to use a method called brazing. Brazing is a process where two pieces of metal are joined together by using a filler metal that has a lower melting point than the base metals. The filler metal is melted and then allowed to cool, which creates a strong bond between the two pieces of metal. Are you a DIY enthusiast looking to join metal pieces together? Then you must have heard about soldering. Soldering is an essential process for creating durable and robust bonds between metals. However, not all metals can be soldered with ease. Knowing which metals are suitable for soldering is crucial to successful metalworking. Different metals may

Press the two pieces together firmly and remove any excess resin with a squeegee or roller. For more intricate connections or repairs, fiberglass matting can be used in conjunction with polyester resin. Cut small sections of matting and apply them between the two pieces, saturating each layer with resin as you go.

When it comes to bonding metal surfaces together, having the right adhesive is key to ensuring a strong and durable bond. Metal can be a tricky surface to wo.

junction box types lowes

Two-Sided Machining. Aspire has the ability to create a project where your design requires you to cut both sides of your material. Typically you will cut the top surface of your material, then .

how to attach two pieces of sheet metal together|how to join sheet metal