sheet metal guy bend calculator Calculate the accurate bend allowance for your sheet metal fabrication with our easy-to-use calculator. Get precise measurements and reduce waste.

No box spring is needed—get superior support from the base’s solid steel frame and sustainable bamboo slats that offer natural durability. Additional center support legs and .

0 · sheet metal calculation formula

1 · sheet metal bend length calculation

2 · sheet metal bend deduction chart

3 · sheet metal bend calculation formula

4 · sheet metal bend allowance chart

5 · calculating bend allowance sheet metal

6 · calculate sheet metal flat pattern

7 · calculate bend radius sheet metal

$275.00

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend .

Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, . Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and .Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Calculate the accurate bend allowance for your sheet metal fabrication with our easy-to-use calculator. Get precise measurements and reduce waste. This sheet metal bend radius calculator can help you quickly and easily determine your project's bend allowance. Simply enter the dimensions of your project into the calculator, .

sheet metal calculation formula

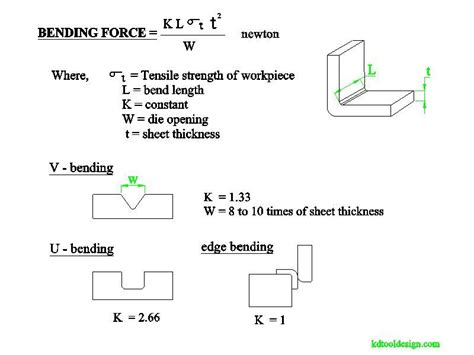

V-Bending Force Calculator. Sheet thickness (in): Die ratio: Die opening (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety: Bending force (lb):With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .Key Features. Accurate Calculations: Provides precise bend allowance and bend deduction values. User-Friendly Interface: Simple and intuitive design for easy use. Automatic Calculation: Real-time updates as you input values. Versatility: .

Enter Sheet Dimensions: Specify the thickness, width, and length of the sheet to be bent. Define Bend Parameters: Set the bend radius, angle, and type of bend (e.g., V-bend, U-bend). Calculate Force: The calculator will automatically compute the required bending force based on the input parameters and material properties.Sheet Metal Cone Calculator View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number . The bending allowance calculator provided below simplifies the process of calculating the bending allowance value, which is crucial for accurate sheet metal fabrication. Bend allowance is the length of the neutral axis between the bend lines, which helps in determining the correct blank size for a bent part.We would like to show you a description here but the site won’t allow us.

Hi I’m new to sheet metal design, can somone explain in simple terms what bend deduction, k factor is etc. and how it’s calculated? Guy who’s training me seems ignorant and rather than explain gave me a list of figures to use, he said use 4mm bend deduction for 2mm thickness, and 5.5 for 3mm thickness which is what we commonly use.

Transition Calculator is useful for Sheet Metal fabrication Industry, Duct manufacturing Industry, Insulation Fabrication Industry, Process Equipment Manufacturing Industry, Pressure Vessel Manufacturing Industry, Piping Industry, Heavy Equipment Fabrication Industry or .The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the arc length of the bend. Therefore, the bend allowance added to the flange lengths is equal to the total flat . Understanding Sheet Metal Bend Allowance Calculator In the realm of sheet metal fabrication, precise calculations are paramount to ensure the accuracy and functionality of the final product. One crucial aspect of this process is the determination of the sheet metal bend allowance , which accounts for the additional material required to form a .I was the waterjet guy for a while. Give me the drawing of the final part, and I'll do the sheet metal layout. There are a lot of adjustments that have to be made to a sheet metal part to get things to line up in the end. A 1/4in hole isn't a 1/4in hole. It's a hole for a 1/4in bolt, so .255 for a close fit and .265 for a loose fit.

The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal. However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table. To use the gauge table, create a sheetmetal part in SolidWorks, after you make your sketch, and you exit sketch you will get your base flange menu. In the sub menu "sheet metal gauges" you will need to check "use gauge table" then select the proper gauge table from the drop down menu. 4. Move down to the sub menu "sheet metal parameters".

For example when sheet metal of length “L” is bend. After bending, the total length (A+B) is larger than length “L”. Click this Link!! To know more about sheet metal k-factor and flat length calculations. Easy to use, the Sheet Metal Software will generate your most complex Flat Pattern layout in a Dxf file in less than 2 minutes. Using MetalFox, you can also: - Optimize Weld lengths to increase your productivity. - Indicate Welding gaps, MetalFox will remove them from Flat Patterns. - Send directly the Dxf file to your Sheet Metal cutting .Cheers for your help. Much appreciated. Im new to sheet metal, thought it be simple, how wrong was i 😂. Got 15 years experience in bespoke machinery. Can i ask one final question. If youre creating a multi bend sheet part, say a hexagon. Is it better to draw the hexagon profile (inc internal or external rads) , extrude, the covert to sheetmetal?Sheet Metal Bend Allowance Calculator Cells shown as light blue editable Units Sheet metal thickness T = in Radius r = in Bend angle φ = deg Calculated Results .

The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers .

To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves creating a controlled deformation to form a . Sheet Metal Bending Calculation. This calculator helps determine the bend length for sheet metal bending operations. Explanation. Calculation Example: The bend length calculation is essential in sheet metal bending to ensure accurate and efficient fabrication. This formula incorporates the sheet thickness (T), bend allowance (B), bend length (L .

Sheet Bending Calculator. Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw size. Sheet Bending Calculator is very helpful in sheet metal fabrication industry, process equipent fabrication industry, heavy equipment fabrication and sheet metal indutsry. You can also use the following calculator to calculate sheet metal unfold length: The following describes the unfolding algorithms of various bend features one by one. General bending I. R = 0mm, θ = 90° (Note: When R ≤ 1.0mm, it is treated as R = 0mm). . Imagine bending sheet metal without leaving a single mark or scratch. In this .

Key Parameters Explained:. Ductility: The ability of a metal to be plastically deformed without fracturing.; Strength (Yield): The stress at which a material begins to plastically deform. Hardness: A measure of a material’s resistance to localized pressure or indentation.; Bend Allowance (BA): The additional length of sheet metal required to form a bend.

K Factor Calculator for Sheet Metal Bending (Online & FREE) Sheet Metal Bending: Everything You Should Know Explained; Bend Deduction Calculator, Formulas & Charts; Precision Sheet Metal Bending with Solidworks Bend Allowance; Press Brake FAQs: Get Your Ultimate Answers; 0° – 180° Bend Allowance Chart for Sheet Metal Bending

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu [email protected] (916) 419-0580; Services. Services;Our supplier has custom k factors calibrated to his machine (evaluated by bending and measuring with different k-factos and then using the best one) . Additional comment actions. The calculator is specially used for sheet metal bending with press brake machine. Reply xd_Warmonger .How to calculate tonnage, internal radius and other bend parameters. This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange.You just have to insert the characteristics of the sheet metal to be bent. The Bend Force Calculator is a crucial tool used in manufacturing and engineering to determine the amount of force required to bend a material to a desired angle or shape. This calculation is essential for industries involved in metalworking, sheet metal fabrication, and other processes where precision bending is necessary.

sheet metal bend length calculation

your choice for responsive turnkey machining and fabrication services

sheet metal guy bend calculator|calculate sheet metal flat pattern