cnc lathe machine tapping cycle I look at how to program a G84 tapping cycle on a CNC milling machine. Each code is explained with a few example programs included. CNC and manual Our people work with a number of high quality metal -working machines such as INDEX, Mori-Seiki, TRAUB, ENSHU and others. We perform all needed operations to .

0 · peck tapping cnc code

1 · g84 cnc tapping cycle

2 · cnc tapping wizard

3 · cnc tapping code generator

4 · cnc mill tapping cycle

5 · cnc g84 tapping speed

6 · cnc code for rigid tapping

7 · can tapping cycle

We offer a wide range of precision sheet metal solutions and are sure that we can assist you in whatever you need. We excel in the supply of subcontract fully fabricated components to a range of industries covering Point of Sale, Electrical & Electronics, Shopfitting, Retail Display & Medical.

peck tapping cnc code

If your machine can’t do Rigid Tapping, you’ll need to use a special tap holder. There are two common types described in our companion article on tapping: a Tapping Head or a Tension-Compression Holder. There are pros and cons for each described in the other article. The purpose of the special holder . See moreTapping is a very commonly used function. Peter Smid says it is second only to drilling holes. It’s easy to program either by hand or using a tool like G-Wizard Editor’s Conversational CNC. . See more

g84 cnc tapping cycle

1. Use GW Editor’s Conversational CNC Tapping Wizards to generate code for the different kinds of tapping so you can see how it should work. . See more

I look at how to program a G84 tapping cycle on a CNC milling machine. Each code is explained with a few example programs included.

What is a G84 CNC code? A G84 command activates the tapping canned cycle. Tapping is threading the female portion of a mating pair. Basically, this means you are creating the thing that will be screwed into. Tapping is .

This canned cycle can be used on the secondary spindle of a Dual Spindle DS lathe, when prefaced by a G14. Refer to the G14 Secondary Spindle Swap for more information. For Axial Live-Tool tapping, use a G95 or G186 command.

Rigid tapping means the tap can remain rigid throughout the tapping cycle. It can be held in a chuck just like an endmill or a drill. The machine spindle locks in with the feedrate just like when you are screw cutting. You can .G84 tap cycle is one of the mostly used function of CNC machining centers. This G84 tapping cycle example program illustrates the use of tapping in an easy to understand way.

The G84 cycle is intended for tapping. This cycle rotates the spindle clockwise to tap a pre-drilled hole; when the bottom of the hole is reached, the spindle rotates in the reverse direction and .

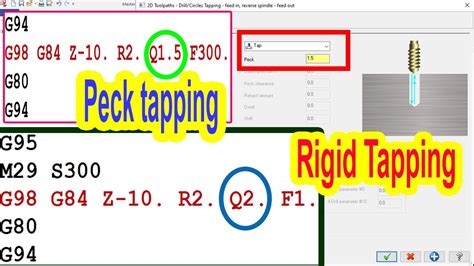

cnc tapping wizard

Most CNC machine types like VMC, HMC, Mill-Turns, CNC Lathes, and CNC Routers can use standard Tapping cycles (G84, M03) and Rigid Tapping (G84, M29). Tapping on a CNC machine presents challenges such as .Tapping a deep hole in rigid tapping mode may be difficult due to chips sticking to the tool (tap) or increased cutting resistance. To make such deep hole tapping operations easy for CNC machinists there is a cycle on Fanuc cnc controls . I am learning about tapping in a CNC lathe and I like to know if there is a ration between RPM and the feed rate. I know for milling there is a ration between TPI and feed rate. . In this article, we’ll be looking at two ways of programming tapping on a CNC: – Tapping Cycles that can use the Rigid Tapping capabilities of your CNC Machine. – Long Form (no canned cycle is needed or used) programming when a Tapping Head or Tension-Compression Tap Holder is to be used on machines that do not have Rigid Tapping.

I look at how to program a G84 tapping cycle on a CNC milling machine. Each code is explained with a few example programs included. What is a G84 CNC code? A G84 command activates the tapping canned cycle. Tapping is threading the female portion of a mating pair. Basically, this means you are creating the thing that will be screwed into. Tapping is done by rotating the spindle, which holds the tap, down through the hole until it reaches the desired depth (bottom of the hole).This canned cycle can be used on the secondary spindle of a Dual Spindle DS lathe, when prefaced by a G14. Refer to the G14 Secondary Spindle Swap for more information. For Axial Live-Tool tapping, use a G95 or G186 command.

Rigid tapping means the tap can remain rigid throughout the tapping cycle. It can be held in a chuck just like an endmill or a drill. The machine spindle locks in with the feedrate just like when you are screw cutting. You can buy tapping heads specially for this.

G84 tap cycle is one of the mostly used function of CNC machining centers. This G84 tapping cycle example program illustrates the use of tapping in an easy to understand way.

The G84 cycle is intended for tapping. This cycle rotates the spindle clockwise to tap a pre-drilled hole; when the bottom of the hole is reached, the spindle rotates in the reverse direction and exits the hole.Most CNC machine types like VMC, HMC, Mill-Turns, CNC Lathes, and CNC Routers can use standard Tapping cycles (G84, M03) and Rigid Tapping (G84, M29). Tapping on a CNC machine presents challenges such as synchronization with the spindle and Z-Axis. Let's keep in touch!Tapping a deep hole in rigid tapping mode may be difficult due to chips sticking to the tool (tap) or increased cutting resistance. To make such deep hole tapping operations easy for CNC machinists there is a cycle on Fanuc cnc controls G84 Peck Rigid Tapping Cycle. I am learning about tapping in a CNC lathe and I like to know if there is a ration between RPM and the feed rate. I know for milling there is a ration between TPI and feed rate. Thanks !

In this article, we’ll be looking at two ways of programming tapping on a CNC: – Tapping Cycles that can use the Rigid Tapping capabilities of your CNC Machine. – Long Form (no canned cycle is needed or used) programming when a Tapping Head or Tension-Compression Tap Holder is to be used on machines that do not have Rigid Tapping.I look at how to program a G84 tapping cycle on a CNC milling machine. Each code is explained with a few example programs included.

What is a G84 CNC code? A G84 command activates the tapping canned cycle. Tapping is threading the female portion of a mating pair. Basically, this means you are creating the thing that will be screwed into. Tapping is done by rotating the spindle, which holds the tap, down through the hole until it reaches the desired depth (bottom of the hole).This canned cycle can be used on the secondary spindle of a Dual Spindle DS lathe, when prefaced by a G14. Refer to the G14 Secondary Spindle Swap for more information. For Axial Live-Tool tapping, use a G95 or G186 command. Rigid tapping means the tap can remain rigid throughout the tapping cycle. It can be held in a chuck just like an endmill or a drill. The machine spindle locks in with the feedrate just like when you are screw cutting. You can buy tapping heads specially for this.G84 tap cycle is one of the mostly used function of CNC machining centers. This G84 tapping cycle example program illustrates the use of tapping in an easy to understand way.

general electric converter box

The G84 cycle is intended for tapping. This cycle rotates the spindle clockwise to tap a pre-drilled hole; when the bottom of the hole is reached, the spindle rotates in the reverse direction and exits the hole.

Most CNC machine types like VMC, HMC, Mill-Turns, CNC Lathes, and CNC Routers can use standard Tapping cycles (G84, M03) and Rigid Tapping (G84, M29). Tapping on a CNC machine presents challenges such as synchronization with the spindle and Z-Axis. Let's keep in touch!Tapping a deep hole in rigid tapping mode may be difficult due to chips sticking to the tool (tap) or increased cutting resistance. To make such deep hole tapping operations easy for CNC machinists there is a cycle on Fanuc cnc controls G84 Peck Rigid Tapping Cycle.

cnc tapping code generator

cnc mill tapping cycle

cnc g84 tapping speed

Anmei U Shaped Connector Bracket, 5 Hole U Shaped Strut Connector Bracket, Height 1-3/4", Width 1-1/2", Thickness 5mm, Fit for 1/2" Bolt in 1-5/8" Strut Channel

cnc lathe machine tapping cycle|cnc tapping code generator