gauge metal fabrication Explore the comprehensive guide to sheet metal gauge charts. Master the art of selecting the perfect metal thickness for your fabrication projects If you are looking to replace that old asphalt roof on your home with a metal roof this Spring, Summer or Fall, but still have a few lingering questions or concerns, then here are the top 70 metal roofing facts, myth-busters, FAQ, plus an overview of costs and pros and cons to consider before making your buying decision. via Birdseye Design.

0 · standard sheet metal gauge

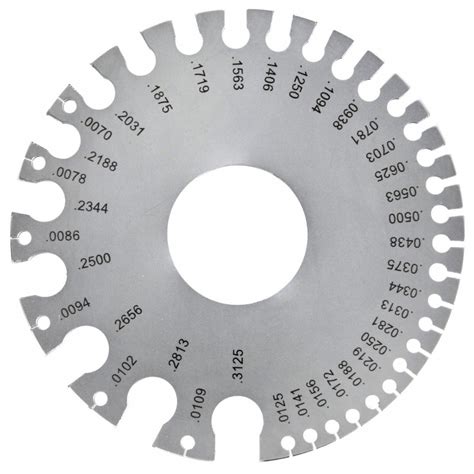

1 · sheet metal gauge wheel

2 · sheet metal gauge tool

3 · sheet metal gauge system

4 · sheet metal gauge size chart

5 · metal gauge chart

6 · how to gauge sheet metal

7 · aluminum sheet metal gauge

Choosing the right metal roof color for your gray house can be tricky. Learn how to pick the perfect shade to complement your home's exterior.

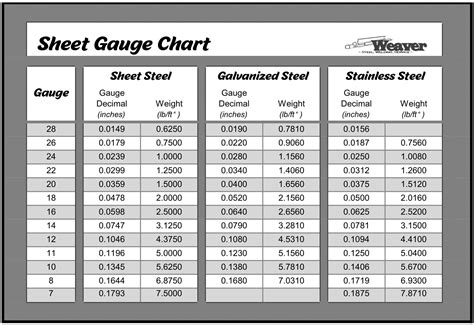

In sheet metal manufacturing, the term “gauge” refers to the thickness of the metal. The thicker the metal, the higher the gauge number. For example, a 12-gauge sheet of metal is thicker than a 14-gauge sheet. . A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The . Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless . The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the .

Explore the comprehensive guide to sheet metal gauge charts. Master the art of selecting the perfect metal thickness for your fabrication projects Welding Cube Kit - 11 Gauge (1/8") Mild Steel . Maybe you've seen the "Cube Challenge" online and wanted to try it, or maybe you've been looking for a way to practice welding without having to prepare your own cut pieces.Or .

Importance of a Back Gauge. In metal fabrication, precision is critical, and a press brake back gauge plays a pivotal role in ensuring accuracy and consistency when bending metal sheets. By providing a dependable reference point for operators, these gauges eliminate guesswork, ensuring precise and repeatable measurements throughout the process. . Hteedy 7inch Metal Bead Roller Machine, RM-08 Sheet Metal Fabrication Bead Roller Rotary Machine 22-Gauge w/6 Dies Rotary Steel Bending Bending Machine for Edging Turning Flattening Smooth. . (177 mm) throat depth sheet metal rotary forming machine, constructed with plate steel and having a capacity of 22 gauge (mild steel), is ideal for .

standard sheet metal gauge

About this item . The sheet metal guillotine shear comes with a sturdy stand ; features a long rubberized handle for maximum leverage. It has a bed length of 52 inch, suitable for cutting metal plate of 16 gauge.STRUCTURAL & FABRICATION STEEL SOLUTIONS. We are experts in steel fabrication solutions both in the light gauge steel and heavy gauge fabrication works. Good steel fabrication leads to better steel structural solutions for you. We are your one-stop shop to your steel project needs. We know steel and steel is our core business.The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. The Manufacturers' Standard Gage provides the thicknesses for standard steel, galvanized steel, and stainless steel.

Description Specifications The shear is hand control and simple operation Special used for thin plates Suitable for metal plate and plastic plate Features: Item NO. : 172108 Model: HS-30 Bed Width(in): 31" Max.shearing thickness(in) : 16ga Packing size(in) :54-1/2x11-1/4x21-1/4 N.W/G.

A press brake angle gauge is a tool used in metal fabrication to measure the angle of a bend. It is an essential tool for ensuring precision and accuracy in the bending process. The press brake angle gauge is designed to be used in conjunction with a press brake machine, which is used to bend sheet metal. .Mika excels at high end, custom sheet metal fabrication of light gauge steel, stainless steel, and aluminum to make products for top brands in North America. We’ve built our reputation on quality craftsmanship and on-time delivery because it’s understood if we . This Guillotine metal shear can be easily coped with all kinds of hard metal plates. For example, mild steel plate, aluminum plate, aluminum alloy plate, electronic galvanized plate, tinned plate, composite steel plate, color coated steel plate, this versatility makes it more convenient for you when working. Long handle design cuts with less . Press brake back gauges are an essential tool in the metal fabrication industry. These devices play a crucial role in ensuring precision and accuracy when bending metal sheets. By providing a reliable reference point for the operator, press brake back gauges help maintain consistent measurements and eliminate guesswork. In this article, I'll delve into the importance .

Cal Steel uses an end-to-end system for rapid and accurate fabrication and construction of structural steel and light gauge steel applications. Our design and build methodology ensures quality buildings, and delivers a faster return on investment and new business opportunities.Lake Air Products is an industry leader that produces thousands of light- to medium-gauge precision metal fabricated parts and components for customers all around the world. With 24/7 automated fabrication capabilities, we can deliver the parts you need with perfect repeatability and lot-to-lot consistency in some of the shortest lead times in . The sheet metal gauge will give you a numerical value that corresponds to the metal’s thickness. This is applicable for sectors where exact measurements are needed. These measurements can be used for component design and fabrication with specified performance and structural criteria. Usage of Sheet Metal Gauge In Sheet Metal Fabrication

Custom Metal Fabrication . With 20 years experience across a broad domain of industries, In Gauge Metal Works offers everything from creative design, fabrication and consultations. . In Gauge Metal Works. 1019 S Wolf Lodge Creek Road. 208-270-7606. [email protected]. Page 1 of 2 - What Gauge metal to use - posted in Fabrication: Looking at giving some welding a go to do some rust repairs on my lj. Before trying it on my on the car, i want to give it a go with just a couple of pieces of scrap but now sure what gauge/thinkness metal to use. I'll be using a gas/gasless mig ive got off a mate. If im hopeless theres no way i'll be touching . Cutting and Fabrication . Light gauge steel frame components are typically cut to precise lengths to meet the specifications of the frames required for the building project, (LGS wall frames, LGS trusses and LGS joists). Additionally, these components are often processed to include openings for electrical wiring and plumbing systems, allowing .

Specialties: In Gauge Metals is a custom Fabrication shop that focuses on Stainless Steel, Aluminum, Copper and Brass metals for both residential, commercial and private projects. We are especially skilled at project design and TIG welding. Our website gives a number of examples of our previous work and finishes. Please visit us there or give a call to discuss any questions or .

TLG is a complete steel framing system for light gauge & cold-formed steel fabrication. Our company specializes in residential, commercial and industrial production, offering flexible and scalable solutions that cater to a wide range of industries and construction needs. We provide custom Light Gauge Steel (LGS) design, supply and install services.

7inch Metal Bead Roller Machine 22-Gauge Sheet Metal Fabrication Bead Roller Rotary Machine Steel Bending Bender Manual Tool w/6 Dies for Edging Turning Sheet Metal Fabrication Shops . Brand: WsrrLun. 9.00 $ 179. 00. Delivery & Support Select to learn more . Ships from LZTUJ . 30-day easy returns . Last updated on July 1st, 2024 at 10:32 am. If you’re new to designing parts for precision sheet metal fabrication, choosing the best material for your part can be daunting.. In addition to selecting the material itself, you need to pick the optimal thickness. The gauge that may instinctively look or feel right isn’t always the best option—there are many factors that go . Below are how to decide gauge for sheet metal fabrication: Scenario. If you have a construction project that requires high rigidity, you’ll have to opt for a lower gauge sheet material. Remember, as discussed earlier, the lower the gauge, the thicker the object. On the other hand, if your construction requires different curves and high .

Sheffield Gauge Plate is not just a world-renowned supplier of tool steel, ground flat stock, waste recycling parts and machine knives; we also offer steel fabrication to transform our tool steel to meet your specific requirements.. Our tool room services will help your project management by allowing you to work with only one supplier for both the tool steel itself and the processing .Spallinger Millwright Services offers custom sheet metal fabrication from light gauge aluminum through heavy gauge stainless plate. We have the ability to field measure and design a solution to fit your specific needs or fabricate to existing drawings. We are proficient with numerous material types including carbon steel, stainless steel .

sheet metal gauge wheel

This organization is not BBB accredited. Sheet Metal Fabrication in Upland, CA. See BBB rating, reviews, complaints, & more.

Sheet metal thickness is denoted by gauge, sometimes spelled gage, which indicates a standard thickness before processing. Click here for a Gauge to mm Conversion Chart.. Processing may include polishing, or the applying of protective plastics which will decrease or increase a sheet’s thickness respectively. What is 16-gauge metal? 16-gauge metal ranges from 0.0598 to 0.0625 inches in thickness. To give you an idea of where this falls on the metal gauge scale, gauges for sheet metal typically range from 7 to 30. So 16-gauge metal falls on the thicker side of the spectrum, lending itself to considerable durability while maintaining flexibility.

1 1 4 x 8 sheet metal screw

sheet metal gauge tool

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal is highly compatible with the process, allowing custom sheet metal fabricators to create diverse products with optimal design versatility and .

gauge metal fabrication|how to gauge sheet metal