electrical control enclosure placement on industrial machinery Control panel design for industrial equipment and machinery is an important undertaking, resulting in an interface designed to control a machine or process. It’s not a simple matter of selecting an appropriate enclosure and a . Find thousands of kitchen with White Cabinets and Stainless Steel Countertops ideas to help you come up with the perfect design for your space. How do I determine my kitchen layout? If you're starting a kitchen renovation, now is a great time to create exactly what you want.

0 · industrial enclosures

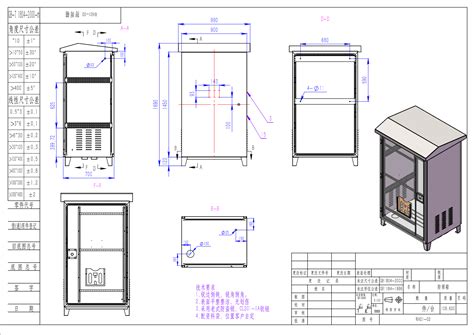

1 · industrial electrical enclosure standards

2 · industrial electrical enclosure specifications

3 · industrial electrical enclosure requirements

4 · industrial electrical enclosure design

5 · industrial appication electrical enclosure

6 · electrical enclosure for industrial use

7 · electrical enclosure design

These sturdy metal brackets have powder-coated finishes for added durability. Select from white, black and silver and other colors to coordinate with your space. Other shelf hardware brackets fit into shelf boards to create a shelving unit that can make a .

These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access the devices to control and operate machinery and systems.Industrial Control Panels and Electrical Equipment of Industrial Machinery for North America A Guide for Practical Use . Reference Manual 08/2014 . A5E02118900A/RS-AA/002 . Disclaimer . Control panel design for industrial equipment and machinery is an important undertaking, resulting in an interface designed to control a machine or process. It’s not a simple matter of selecting an appropriate enclosure and a . Industrial control panel enclosures are protective housings that contain electrical and electronic components. They are designed to shield these components from environmental .

To design as efficiently as possible without dangerously cutting corners, follow these layout-specific control panel tips: Industrial-grade control panels are complex creatures to lay out. Focus on these nine areas of design: . These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and .

Industrial control panels contain the heart of a controlled system. The National Electrical Code (NEC) is a standard for the design and safe installation of electrical equipment in the United States. NEC and related .Control panels contain electrical components and devices that allow for the automation of industrial processes and equipment. When designing a custom control panel, there are a number of key aspects to consider to ensure your . Sizing an enclosure is a task of balancing internal space, external installation room and cost. The enclosure obviously must be big enough to house the contents with proper space tolerances, and interior space must be .These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access the devices to control and operate machinery and systems.

Industrial control panels (ICPs) contain electrical devices and control devices. Because of the different types of components, several standards and regulations apply to ICP design, production, and installation. ICPs must comply with .Industrial Control Panels and Electrical Equipment of Industrial Machinery for North America A Guide for Practical Use . Reference Manual 08/2014 . A5E02118900A/RS-AA/002 . Disclaimer of Liability . 1 . 2. Introduction . Area of application for this . documentation . 3. General information for . manufacturers of machinery and their associated . Control panel design for industrial equipment and machinery is an important undertaking, resulting in an interface designed to control a machine or process. It’s not a simple matter of selecting an appropriate enclosure and a back panel that . Industrial control panel enclosures are protective housings that contain electrical and electronic components. They are designed to shield these components from environmental hazards like dust, moisture, and temperature variations, ensuring safe and reliable operation.

To design as efficiently as possible without dangerously cutting corners, follow these layout-specific control panel tips: Industrial-grade control panels are complex creatures to lay out. Focus on these nine areas of design: 1. Make Your Schematic Count.

industrial enclosures

industrial electrical enclosure standards

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards. Industrial control panels contain the heart of a controlled system. The National Electrical Code (NEC) is a standard for the design and safe installation of electrical equipment in the United States. NEC and related regulations dictate many features of ICPs.

Control panels contain electrical components and devices that allow for the automation of industrial processes and equipment. When designing a custom control panel, there are a number of key aspects to consider to ensure your panel operates properly, is safe to .

Sizing an enclosure is a task of balancing internal space, external installation room and cost. The enclosure obviously must be big enough to house the contents with proper space tolerances, and interior space must be sufficient for fabricators and maintenance personnel.These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access the devices to control and operate machinery and systems. Industrial control panels (ICPs) contain electrical devices and control devices. Because of the different types of components, several standards and regulations apply to ICP design, production, and installation. ICPs must comply with .

Industrial Control Panels and Electrical Equipment of Industrial Machinery for North America A Guide for Practical Use . Reference Manual 08/2014 . A5E02118900A/RS-AA/002 . Disclaimer of Liability . 1 . 2. Introduction . Area of application for this . documentation . 3. General information for . manufacturers of machinery and their associated . Control panel design for industrial equipment and machinery is an important undertaking, resulting in an interface designed to control a machine or process. It’s not a simple matter of selecting an appropriate enclosure and a back panel that . Industrial control panel enclosures are protective housings that contain electrical and electronic components. They are designed to shield these components from environmental hazards like dust, moisture, and temperature variations, ensuring safe and reliable operation.

To design as efficiently as possible without dangerously cutting corners, follow these layout-specific control panel tips: Industrial-grade control panels are complex creatures to lay out. Focus on these nine areas of design: 1. Make Your Schematic Count. These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards. Industrial control panels contain the heart of a controlled system. The National Electrical Code (NEC) is a standard for the design and safe installation of electrical equipment in the United States. NEC and related regulations dictate many features of ICPs.

Control panels contain electrical components and devices that allow for the automation of industrial processes and equipment. When designing a custom control panel, there are a number of key aspects to consider to ensure your panel operates properly, is safe to .

industrial electrical enclosure specifications

metal roofing inside house

$298.30

electrical control enclosure placement on industrial machinery|industrial electrical enclosure requirements