diy cnc table parts We will provide a step-by-step walkthrough for how to build your very own DIY CNC plasma table, including a list of required tools and equipment, as well as a guide. See more GenMet’s ventilated enclosures were designed with power components such as reactors and capacitors in mind. Each enclosure can serve either Nema Type1 indoor or Type 3R outdoor applications.

0 · onefinity cnc table plans

1 · homemade cnc plasma table plans

2 · homemade cnc plasma table

3 · home built cnc plasma table

4 · diy cnc table plans

5 · cnc plasma table for beginners

6 · build your own plasma table

7 · build your own cnc table

EASY ASSEMBLY: Our corten steel planters comes in flat, economical packaging with hardware and instructions on how to easily transform your panels into a planter that will bring your space to life ; MODERN, RUSTIC DECOR: The Long Box planter features clean lines to complement your contemporary aesthetic.

onefinity cnc table plans

Making your own CNC plasma table is a great alternate option to buying a brand new table, as they can range from 20,000 dollars to well over 50,000 for a high-quality, industrial-grade unit. It is possible to make your own CNC plasma table for much cheaper by purchasing and using your own tools and materials . See moreWe will provide a step-by-step walkthrough for how to build your very own DIY CNC plasma table, including a list of required tools and equipment, as well as a guide. See more

The difference between a DIY CNC plasma table and a professionally made CNC plasma table will depend on a number of factors. If . See more

home depot thin metal sheets

In this informational article, we have explored the idea of creating your own DIY CNC plasma table. We have discussed everything from versatility to the potential cost of building your . See moreAll the parts need to be cut in 3mm or 1/8" mild steel A366/1008 Grade (or 304 Grade Stainless). The parts are suitable for both metric and imperial box section / nuts & bolts if you just pick the . In today's video we add the the motors and drivers and belts for the XL table.Plans and parts for the XL table - https://jdsgarage.bigcartel.com/category/pla. In this informational article, we have explored the idea of creating your own DIY CNC plasma table. We have discussed everything from versatility to the potential cost of building your own table, as well as provided a step-by-step guide that .

Learn to create and import CAD designs, convert them to G-code, and operate the table safely. Regular maintenance, including cleaning and lubricating moving parts, is crucial for optimal performance.All the parts need to be cut in 3mm or 1/8" mild steel A366/1008 Grade (or 304 Grade Stainless). The parts are suitable for both metric and imperial box section / nuts & bolts if you just pick the closest size.

In today's video we add the the motors and drivers and belts for the XL table.Plans and parts for the XL table - https://jdsgarage.bigcartel.com/category/pla. Building a CNC plasma table at home is as awesome as it sounds, albeit a little dangerous. Learn how to use computer controlled motion to automatically and precisely move around the plasma stream to cut metal.

To build a plasma table, you’ll need various mechanical parts such as linear rails, stepper motors, a power supply, and a control board. You’ll also need metal tubing for the frame, caster wheels for mobility, and a gear rack for movement precision.Detailed step-by-step instructions for building your CNC plasma cutting table; Comprehensive lists of tools, materials and parts required, with online sources; Design principles and considerations for a durable and cost-effective table; Troubleshooting tips and maintenance advice for .Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The precisely cut.Budget DIY CNC Plasma Table Build / Plasma Cutter. Here is a list of all the items I purchased from scamazon as well as quantity needed and placement. Proma MyPlasm CNC Controller info as.

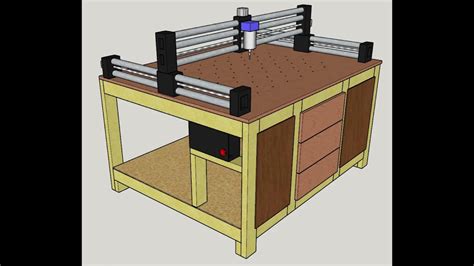

DIY CNC Table Build - FREE Plans: In this project, I’m showing how I made this sturdy, but inexpensive CNC table. It could also be used as an outfeed table for your table saw, or even just as a workbench. Watch the video and follow along with the steps below! In this informational article, we have explored the idea of creating your own DIY CNC plasma table. We have discussed everything from versatility to the potential cost of building your own table, as well as provided a step-by-step guide that .

Learn to create and import CAD designs, convert them to G-code, and operate the table safely. Regular maintenance, including cleaning and lubricating moving parts, is crucial for optimal performance.

All the parts need to be cut in 3mm or 1/8" mild steel A366/1008 Grade (or 304 Grade Stainless). The parts are suitable for both metric and imperial box section / nuts & bolts if you just pick the closest size.

In today's video we add the the motors and drivers and belts for the XL table.Plans and parts for the XL table - https://jdsgarage.bigcartel.com/category/pla. Building a CNC plasma table at home is as awesome as it sounds, albeit a little dangerous. Learn how to use computer controlled motion to automatically and precisely move around the plasma stream to cut metal.To build a plasma table, you’ll need various mechanical parts such as linear rails, stepper motors, a power supply, and a control board. You’ll also need metal tubing for the frame, caster wheels for mobility, and a gear rack for movement precision.Detailed step-by-step instructions for building your CNC plasma cutting table; Comprehensive lists of tools, materials and parts required, with online sources; Design principles and considerations for a durable and cost-effective table; Troubleshooting tips and maintenance advice for .

Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The precisely cut.Budget DIY CNC Plasma Table Build / Plasma Cutter. Here is a list of all the items I purchased from scamazon as well as quantity needed and placement. Proma MyPlasm CNC Controller info as.

home run junction box

Crafted from durable galvanized steel, these planters can withstand the harshest of weather, and the insulated.

diy cnc table parts|homemade cnc plasma table