aluminum sheet metal stamping We provide metal stamped parts and additional stamping solutions for all . Model: AK8200AS. Transform your cooking experience with the Zephyr Power Tornado II Series AK8200AS. Type: Cabinet Insert. Blower Type: Internal.

0 · stamping steel

1 · sheet metal stamping process

2 · metal stamping facilities near me

3 · metal dye stamp

4 · diy metal stamping press

5 · best aluminum for stamping

6 · aluminum washers for metal stamping

7 · aluminum stamping companies

LOCATOR Attachment System is the most globally recognized and trusted brand for overdenture restorations. Combining innovative patented technology with availability in more than 280 implant connections has propelled it to be the preferred choice of clinicians with more than 4 million satisfied patients.

metal fabrication companies in richmond va

Learn how Winco Stamping can provide low-cost, custom stamping for aluminum sheets with favorable lead times to meet your needs and budget.We provide metal stamped parts and additional stamping solutions for all .

Custom Copper Stamped Parts. Winco Stamping provides short run and .Custom Hot Rolled Steel Stamped Parts. Winco Stamping provides custom hot .Winco Stamping’s in-house tool building process is second to none in the .Cold Rolled Steel Stamping Services by Winco Stamping. Winco Stamping has .

metal fabrication colleges

CUSTOM STAINLESS STEEL STAMPING. Winco Stamping is America’s trusted .Custom aluminum sheet metal stamping in alloys 1100, 3003, 5052, 6061, 6063, 2024, 7075 & more. High quality, quick turnaround, free quote.Stamping aluminum in metal fabrication is a high-speed, high-volume manufacturing process. It involves using specialized tools and dies to shape flat sheet metal into specific forms. For aluminum stamping, we start with . Metal stamping refers to several forming processes, typically used to transform a standard aluminum product into smaller parts. Different techniques involved in the aluminum .

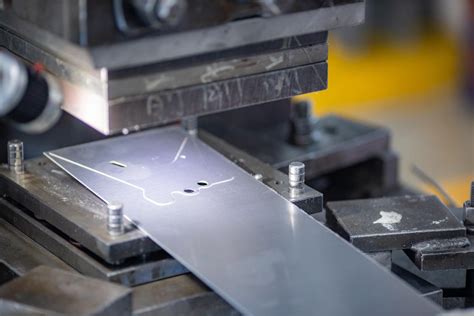

Aluminum sheet metal stamping, a crucial manufacturing technique, involves transforming aluminum sheets into specific shapes and designs using high-pressure machinery. Renowned for its precision and efficiency, this process .Sheet metal stamping involves using dies and stamping presses to shape flat metal sheets into specific designs. In this process, pressure is applied to cut, bend, or form the sheet into the .

Metal stamping is a shaping process that uses dies and stamping presses. A die of a specific shape is made. A flat aluminum piece goes in the stamping machine. The press applies force on the aluminum against the die. As a result, . At its core, aluminum stamping is an art form blended with science. It involves transforming aluminum sheets into specific shapes and designs using a combination of pressure and precision tooling. The journey of aluminum .Aluminum: Aluminum is lightweight and resistant to corrosion. It’s famous for industries looking to save weight without sacrificing strength. Stainless Steel: Stainless steel, known for its corrosion resistance and strength, is an excellent .Learn how Winco Stamping can provide low-cost, custom stamping for aluminum sheets with favorable lead times to meet your needs and budget.

1. What is Aluminum Stamping? Stamping aluminum is a metal fabrication technique where you use dies to make shapes and patterns on sheet metal. 2. Is Aluminum Good for Stamping? Yes. Aluminum exhibits good workability and strength. You can easily transform aluminum into any shape and design. You can stamp aluminum parts easily. 3.Custom aluminum sheet metal stamping in alloys 1100, 3003, 5052, 6061, 6063, 2024, 7075 & more. High quality, quick turnaround, free quote.

Stamping aluminum in metal fabrication is a high-speed, high-volume manufacturing process. It involves using specialized tools and dies to shape flat sheet metal into specific forms. For aluminum stamping, we start with aluminum sheet stock.

Metal stamping refers to several forming processes, typically used to transform a standard aluminum product into smaller parts. Different techniques involved in the aluminum metal stamping process are given by: Blanking: The blanking process forms a die to cut out a workpiece from an aluminum sheet metal piece.Aluminum sheet metal stamping, a crucial manufacturing technique, involves transforming aluminum sheets into specific shapes and designs using high-pressure machinery. Renowned for its precision and efficiency, this process ensures the .Sheet metal stamping involves using dies and stamping presses to shape flat metal sheets into specific designs. In this process, pressure is applied to cut, bend, or form the sheet into the desired shape.Metal stamping is a shaping process that uses dies and stamping presses. A die of a specific shape is made. A flat aluminum piece goes in the stamping machine. The press applies force on the aluminum against the die. As a result, aluminum cuts .

At its core, aluminum stamping is an art form blended with science. It involves transforming aluminum sheets into specific shapes and designs using a combination of pressure and precision tooling. The journey of aluminum stamping starts with a flat sheet of Aluminum.Aluminum: Aluminum is lightweight and resistant to corrosion. It’s famous for industries looking to save weight without sacrificing strength. Stainless Steel: Stainless steel, known for its corrosion resistance and strength, is an excellent choice for components that .Learn how Winco Stamping can provide low-cost, custom stamping for aluminum sheets with favorable lead times to meet your needs and budget.

1. What is Aluminum Stamping? Stamping aluminum is a metal fabrication technique where you use dies to make shapes and patterns on sheet metal. 2. Is Aluminum Good for Stamping? Yes. Aluminum exhibits good workability and strength. You can easily transform aluminum into any shape and design. You can stamp aluminum parts easily. 3.Custom aluminum sheet metal stamping in alloys 1100, 3003, 5052, 6061, 6063, 2024, 7075 & more. High quality, quick turnaround, free quote.

Stamping aluminum in metal fabrication is a high-speed, high-volume manufacturing process. It involves using specialized tools and dies to shape flat sheet metal into specific forms. For aluminum stamping, we start with aluminum sheet stock. Metal stamping refers to several forming processes, typically used to transform a standard aluminum product into smaller parts. Different techniques involved in the aluminum metal stamping process are given by: Blanking: The blanking process forms a die to cut out a workpiece from an aluminum sheet metal piece.Aluminum sheet metal stamping, a crucial manufacturing technique, involves transforming aluminum sheets into specific shapes and designs using high-pressure machinery. Renowned for its precision and efficiency, this process ensures the .

Sheet metal stamping involves using dies and stamping presses to shape flat metal sheets into specific designs. In this process, pressure is applied to cut, bend, or form the sheet into the desired shape.Metal stamping is a shaping process that uses dies and stamping presses. A die of a specific shape is made. A flat aluminum piece goes in the stamping machine. The press applies force on the aluminum against the die. As a result, aluminum cuts .

stamping steel

At its core, aluminum stamping is an art form blended with science. It involves transforming aluminum sheets into specific shapes and designs using a combination of pressure and precision tooling. The journey of aluminum stamping starts with a flat sheet of Aluminum.

sheet metal stamping process

metal stamping facilities near me

Root Kill dissolves the roots of trees and shrubs penetrating cracks of poorly sealed joints in pipes. The professional-strength, granular formula works on contact but does not harm trees and shrubs. It is safe for septic systems and .

aluminum sheet metal stamping|metal dye stamp