drill hole in plastic junction box You need to drill a hole so you might as well drill the proper sized hole. I only punch metal 2" and up because the larger size hole saws have too much surface area to cover and it takes freaking forever.

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

0 · plastic electrical box cutting

1 · drilling hole in junction box

2 · drilling a junction box

3 · drill bit for junction box

4 · cutting hole in plastic electrical box

5 · cutting hole in plastic box

We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

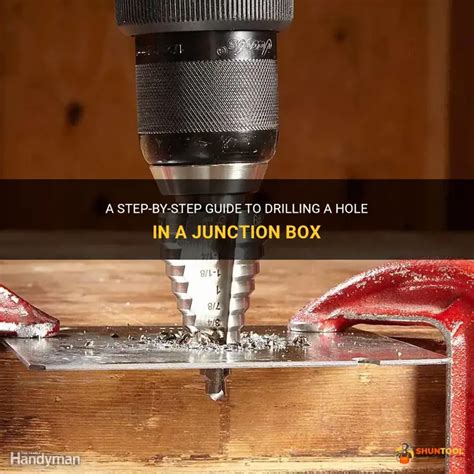

I have never had an AHJ object to sing a Greenlee punch to add/move a hole in a panel, but I have never needed to do the same for a junction box. Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the p. When drilling a hole in a junction box, it's crucial to use the right drill bit to prevent damage to the box and ensure a clean hole. For plastic junction boxes, a general-purpose high-speed steel or carbide-tipped drill bit is suitable. IBEW member Jennifer Smith leads this weeks job tip by showing us how to drill into a junction box or panel without breaking your drill bit. .more. First, you will need a cordless.

By drilling a hole in the junction box, you create a designated entry point for the wires to enter and exit the box. This ensures that the wires are tightly secured and cannot be .

You need to drill a hole so you might as well drill the proper sized hole. I only punch metal 2" and up because the larger size hole saws have too much surface area to cover and it takes freaking forever. First prepare an awl and a lighter, then heat the awl until red hot, and then directly drill holes in the electrical junction box. To get neater holes, it is recommended to punch the holes from the reverse side of the plastic.You can definitely drill holes, but the preferred method is to use a knockout set so you don't get metal shavings into the electrical components.

Drilling junction boxes may seem like a simple task, but it requires precision and attention to detail. By following the steps outlined in this guide, you can ensure that your .

Once you’ve determined the optimal location, follow these steps to drill the hole for your junction box: 1. Mark the drilling location: Using a pencil, mark the center point of the . I have never had an AHJ object to sing a Greenlee punch to add/move a hole in a panel, but I have never needed to do the same for a junction box. Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the p. When drilling a hole in a junction box, it's crucial to use the right drill bit to prevent damage to the box and ensure a clean hole. For plastic junction boxes, a general-purpose high-speed steel or carbide-tipped drill bit is suitable.

IBEW member Jennifer Smith leads this weeks job tip by showing us how to drill into a junction box or panel without breaking your drill bit. .more. First, you will need a cordless. By drilling a hole in the junction box, you create a designated entry point for the wires to enter and exit the box. This ensures that the wires are tightly secured and cannot be easily pulled out or damaged. Drilling a hole in a junction box also helps maintain the integrity of . You need to drill a hole so you might as well drill the proper sized hole. I only punch metal 2" and up because the larger size hole saws have too much surface area to cover and it takes freaking forever. First prepare an awl and a lighter, then heat the awl until red hot, and then directly drill holes in the electrical junction box. To get neater holes, it is recommended to punch the holes from the reverse side of the plastic.

You can definitely drill holes, but the preferred method is to use a knockout set so you don't get metal shavings into the electrical components.

plastic electrical box cutting

drilling hole in junction box

Drilling junction boxes may seem like a simple task, but it requires precision and attention to detail. By following the steps outlined in this guide, you can ensure that your junction boxes are installed correctly and safely.

Once you’ve determined the optimal location, follow these steps to drill the hole for your junction box: 1. Mark the drilling location: Using a pencil, mark the center point of the junction box on the wall. 2. Pilot hole: Drill a small pilot hole using a drill bit slightly smaller than the diameter of the junction box mounting holes. This .

I have never had an AHJ object to sing a Greenlee punch to add/move a hole in a panel, but I have never needed to do the same for a junction box.

Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the p.

When drilling a hole in a junction box, it's crucial to use the right drill bit to prevent damage to the box and ensure a clean hole. For plastic junction boxes, a general-purpose high-speed steel or carbide-tipped drill bit is suitable.IBEW member Jennifer Smith leads this weeks job tip by showing us how to drill into a junction box or panel without breaking your drill bit. .more. First, you will need a cordless. By drilling a hole in the junction box, you create a designated entry point for the wires to enter and exit the box. This ensures that the wires are tightly secured and cannot be easily pulled out or damaged. Drilling a hole in a junction box also helps maintain the integrity of . You need to drill a hole so you might as well drill the proper sized hole. I only punch metal 2" and up because the larger size hole saws have too much surface area to cover and it takes freaking forever.

First prepare an awl and a lighter, then heat the awl until red hot, and then directly drill holes in the electrical junction box. To get neater holes, it is recommended to punch the holes from the reverse side of the plastic. You can definitely drill holes, but the preferred method is to use a knockout set so you don't get metal shavings into the electrical components.

Drilling junction boxes may seem like a simple task, but it requires precision and attention to detail. By following the steps outlined in this guide, you can ensure that your junction boxes are installed correctly and safely.

drilling a junction box

drill bit for junction box

There are different types of sheet metal screws that are made specifically for different material engagement and fitting purposes. The variation in the parameters such as the thread pattern, .

drill hole in plastic junction box|plastic electrical box cutting