metal needle fabrication This paper presents the fabrication of silicon hollow microneedles by a deep-reactive ion etching (DRIE) process, with the aim of exploring the feasibility of microneedle . A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

0 · microneedle molding

1 · how to make microneedles

A junction box is an essential part of the electrical wiring systems for homes and commercial buildings. These metal or plastic boxes house and safely protect a structure's electrical connections. The electrical casings come in .

In this review, we provide an overview of multiscale needle fabrication techniques and their biomedical applications. Needles are . This study describes the fabrication and characteristics of microneedle array electrodes (MAEs) using Bismuth–Indium–Tin (Bi–In–Sn) alloys. The MAEs consist of 57 .A combination of photolithography, metal deposition, and selective etching was used for the fabrication of the microneedles. The manufacturing process is by using photolithography to . This paper presents the fabrication of silicon hollow microneedles by a deep-reactive ion etching (DRIE) process, with the aim of exploring the feasibility of microneedle .

Electroplating is a widely used process in the fabrication of micro-needles, particularly in drug delivery applications. This technique is essential due to its ability to produce thin, precise .In the past years, in-plane and out-of-plane microneedle technologies made by silicon (Si), polymer, metal, and other materials have been developed for numerous biomedical . In this review, technical challenges associated with microneedle processing are considered. The mechanical requirements associated with microneedle penetration of the skin . The ongoing challenges are the materials and fabrication methods of the microneedles in order to obtain a specific shape, configuration and function of the microneedles to achieve a target biomedical application. Here, this .

METAL FABRICATION. Hart Enterprises, Inc. takes great pride in our ability to create custom needles. Each of our production department heads have over 20 years of experience with Hart. This continuity over the years enables Hart . Hollow microneedles can penetrate the corneum of the skin and various biological barriers. Drugs can enter through a minimally invasive path or bodily fluid can be collected from the epidermis or dermis. This makes hollow microneedles (MN) a promising tool for drug delivery and body fluid sensing in a painless manner. Here, we propose a nickel microneedle with a .By creating this content, your metal fabrication brand stands out in search results and positions itself as an authority and thought leader, leading searchers to work with you when they’re ready to move forward. Learn more about the . The profile of outside needles is achieved by the developed fabrication process, which combined isotropic etching and anisotropic etching with inductively coupled plasma (ICP) etcher.

Arrays of micrometer-scale needles could be used to deliver drugs, proteins, and particles across skin in a minimally invasive manner. We therefore developed microfabrication techniques for silicon, metal, and biodegradable polymer microneedle arrays having solid and hollow bores with tapered and beveled tips and feature sizes from 1 to 1,000 μm. First, fabrication of metal and polymer microneedles should be less expensive and readily scalable to mass production because: (i) metal and polymer raw materials are widely available and generally less expensive than silicon wafers, (ii) the electroplating and polymer molding techniques used to make these needles can be set up in a . Micro-needle (MN), a kind of micro-device, has been proposed to act as drug delivery systems since 1990s. It can be made from silicon, metal, polymer and ceramic materials. A broad range of biopharmaceuticals are delivered by MN into skin, especially the supra-molecule which can not get through the stratum corneum.

Table 1 Needle types based on fabrication parameters, including engraving speed and length of the lines in COL design. Full size table. Microneedle shape characterization.

microneedle molding

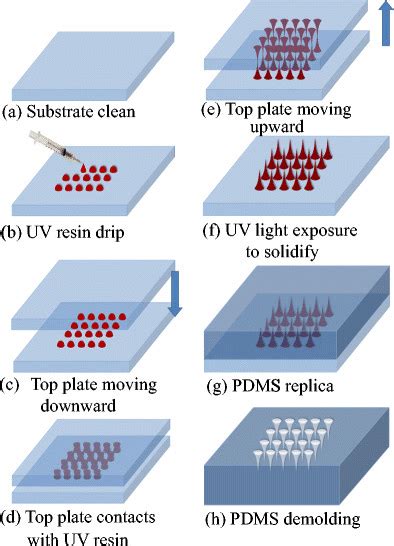

Reusable Stainless Steel Hypodermic Needles. Medical hypodermic needles (or needle assemblies) typically consist of a machined fitting joined to a fabricated tube. Most often, the tube is stainless steel and pointed or blunt (click on cannula link for more details).Depending on their diameter, needles can be classi-ed into nanoneedles, microneedles and millineedles. Owing to the scale eects of nano/micro/milli needles, dierent fabrication strategies and biomedical applica-tions have been developed, as shown in Table 1. In this review, we provide an overview of multiscale needle fab-Polymer materials, such as PMMA and PDMS, have been of great interest in the research and development of MEMS recently due to their relatively low cost and easy process. In this research, we are trying to fabricate Ni Micro needle array from PMMA master by through PDMS mold based on multi-mold transformation technology. The fabricated micro nickel needles array is 900 .

For micro-needle fabrication, techniques like reactive ion etching (RIE) or plasma treatment can be employed to increase surface area and enhance the adhesion properties. . After the electroplating process, which deposits the desired metal onto a substrate to form needles, several treatments may be necessary to enhance the micro-needles .Common materials for micro-needle fabrication include metals, polymers, and ceramics. Each material type has its own advantages and challenges. Metallic micro-needles, like those made from stainless steel or titanium, often offer superior strength and durability, making them suitable for creating sharper needles that can penetrate skin effectively.Pliers: Pliers are used to bend and grip metal. Needle-nose pliers, slip-joint pliers, and locking pliers are all useful for different tasks. Screwdrivers: Screwdrivers are used to tighten and loosen screws and bolts. . Metal fabrication is a complex and demanding process that requires specialized tools and equipment. From hand tools and .Our Medical Needles Division offers the widest range of reusable, metal-hubbed needles from a standard hypodermic needle to the most complex biopsy needles. Our procedures needles include Anesthesia Needles, Biopsy Needles, .

Metal HMN arrays with high quality are prepared with great flexibility with tunable parameters of area, length of needle, size of hollow and array dimension. This efficient and cost-effective fabrication method can also be applied to other applications after minor alterations, such as preparation of optic, acoustic and solar harvesting . This enables the fabrication of intricate metal patterns and the use of metals with low melting points for MAEs. Recently, a study has been presented on the development of non-reusable intravenous needles using Gallium (Ga) metal, known for its low melting point 17. This research on needles utilizing such low-melting-point metals is expanding .Hickey Metal Fabrication is a nationally-recognized fabricating powerhouse. Increase the scope and scale of production through our State-of-the-art Automation in our seven-plant, 400,000+ square foot facility. Hickey Metal Fabrication is a nationally-recognized fabricating powerhouse. Increase the scope and scale of production through our State .Fabrication, Machining, Welding, Finishing and Assembly Hutchinson Manufacturing has tackled the complex, custom metal fabrication that other companies won’t touch, as well as large contract volume metal manufacturing. Our manufacturing space is located in Hutchinson, Minnesota and can perform virtually all metal and steel fabrication, machining, cladding and welding and .

Vita Needle provides first-class and affordable custom manufacturing in stainless, nickel, brass, aluminum and copper steel tube fabrication, in addition to other alloys. Since 1932, Vita Needle has built a reputation for superior quality, service and value. Vita services a wide range of markets from medical/laboratory to industrial to machine . Needles are classified as nanoneedles, microneedles and millineedles based on the needle diameter, and their fabrication techniques are highlighted. Nanoneedles bridge the inside and outside of . Microneedles are microscale needle-shaped devices that have attracted attention from the biomedical engineering community for transdermal drug delivery, sensing, and vaccine delivery. These devices do not inflict significant discomfort during skin penetration. Microneedles have recently been used to detect physiologically relevant molecules in interstitial fluid for .

how to make microneedles

Microneedle arrays (MA) have been extensively investigated in recent decades for transdermal drug delivery due to their pain-free delivery, minimal skin trauma, and reduced risk of infection. However, porous MA received relatively less attention due to their complex fabrication process and ease of fracturing. Here, we present a titanium porous microneedle array (TPMA) . (b) After fabricating MAE in a vacuum environment, the sharpness of the needle tip decreases to below 10 μm. (c) Image of Bi–In–Sn MAE before PUA coating, along with its magnified SEM image. The microneedles have attracted great interests for a wide range of transdermal biomedical applications, such as biosensing and drug delivery, due to the advantages of being painless, semi-invasive, and sustainable. The ongoing challenges are the materials and fabrication methods of the microneedles in order to obtain a specific shape, configuration and . Silicon, metal and polymer were always adopted to fabricate MEs. Photolithography technology with wet or dry etching has been widely used in the fabrication of MEs from silicon wafers. . Micro-Needle Array (MA) Fabrication. MSM was developed to fabricate MA. The magnetization-induced MA equipment is shown in Figure 2 a. This .

The Pica Dry Metal Set is the ultimate marking solution for professional metalworkers and DIYers alike. This set includes a durable metal scribing needle for precise marking on all metal surfaces, even rough or textured ones, and a refillable Pica Dry pencil compatible with versatile graphite lead 2B that marks on a variety of surfaces, from dry to glossy.

A sharp bend is the smallest radius you can air-bend a part short of stamping it, and the average for this is 63 percent of the material thickness. It’s a function of the relationship between material type, tensile, yield, and thickness.

metal needle fabrication|how to make microneedles