bending copper sheet metal This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. With 17 years of professional CNC machining experience, AS Precison provides various precision CNC parts machining services for global customers.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Our state-of-the-art facility offers custom metal stamping parts with advantages over our competitors. Learn how Winco can help you today!

In summary, this guide provides comprehensive insights into the art of bending copper sheets, covering everything from understanding copper properties to safety measures. It’s an invaluable resource for anyone looking to enhance .Unlock the secrets of bending copper sheets in our detailed guide. Learn the techniques, tools and safety measures to shape copper sheet.In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet .

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.In summary, this guide provides comprehensive insights into the art of bending copper sheets, covering everything from understanding copper properties to safety measures. It’s an invaluable resource for anyone looking to enhance their metal fabrication skills . Bending copper sheets can be a daunting task. It’s a material that is malleable enough to bend but also strong enough to retain its shape when bent. But with the right tools and techniques, you can easily learn how to bend copper sheets like a pro. This blog post will show you how to do just that!Unlock the secrets of bending copper sheets in our detailed guide. Learn the techniques, tools and safety measures to shape copper sheet.

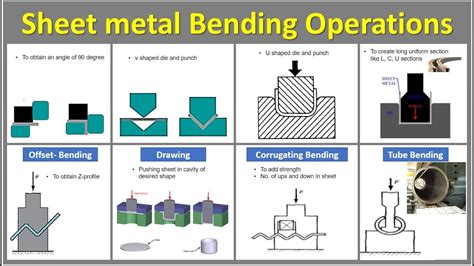

In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.) Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Coining is a very accurate sheet metal bending wherein the metal is fully embraced by the die to achieve the correct angle. It uses full punch force and this makes it to be very precise and creates unique sharp angles that do not fade away easily.

types of bending sheet metal

Common copper grades for sheet metal bending include: C11000 (Electrolytic Tough Pitch): Known for its high conductivity, commonly used in electrical busbars and roofing. C12200 (DHP Copper): Offers excellent formability, making it ideal for plumbing and HVAC applications.

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal structure.

In summary, this guide provides comprehensive insights into the art of bending copper sheets, covering everything from understanding copper properties to safety measures. It’s an invaluable resource for anyone looking to enhance their metal fabrication skills . Bending copper sheets can be a daunting task. It’s a material that is malleable enough to bend but also strong enough to retain its shape when bent. But with the right tools and techniques, you can easily learn how to bend copper sheets like a pro. This blog post will show you how to do just that!Unlock the secrets of bending copper sheets in our detailed guide. Learn the techniques, tools and safety measures to shape copper sheet.In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.)

sheet metal bending standards

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Coining is a very accurate sheet metal bending wherein the metal is fully embraced by the die to achieve the correct angle. It uses full punch force and this makes it to be very precise and creates unique sharp angles that do not fade away easily.

metal tool box design

Common copper grades for sheet metal bending include: C11000 (Electrolytic Tough Pitch): Known for its high conductivity, commonly used in electrical busbars and roofing. C12200 (DHP Copper): Offers excellent formability, making it ideal for plumbing and HVAC applications.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.

sheet metal bending near me

sheet metal bending guidelines

sheet metal bending chart

problems with sheet metal bending

Offers low-cost custom motorcycle CNC parts such as engine parts, cylinders, camshafts, pistons, etc. All motorcycle CNC parts are inspected, and quality tested before shipping with a material certificate.

bending copper sheet metal|problems with sheet metal bending